Lifting appliance for stable lifting of port steel pipe stacking and carrying crane

A technology for cranes and steel pipes, which is applied in the field of spreaders for stable lifting of steel pipe stacking and handling cranes in ports. It can solve problems such as lifting shaking, safety accidents, and uncertain quantities, and achieve safe and stable lifting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

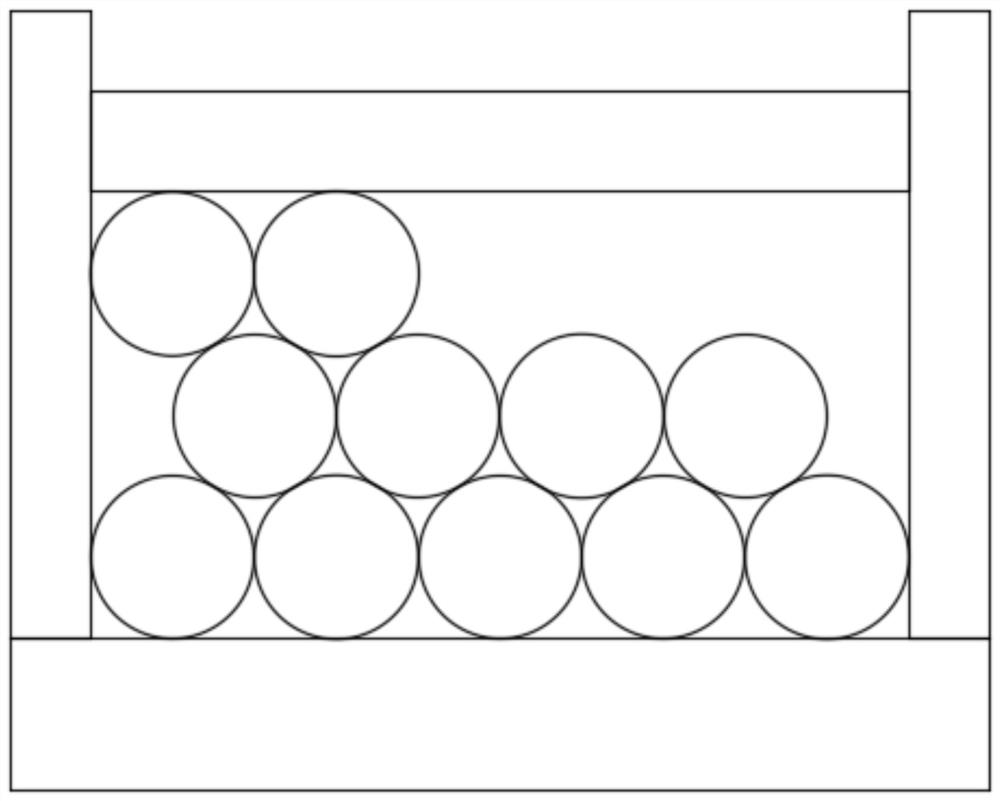

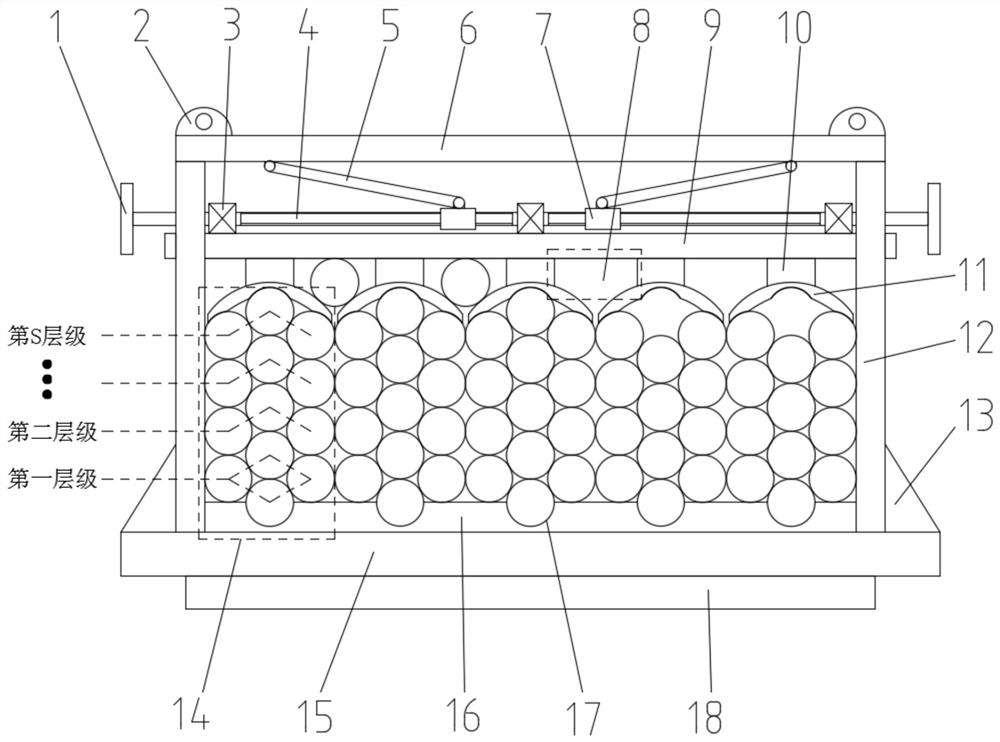

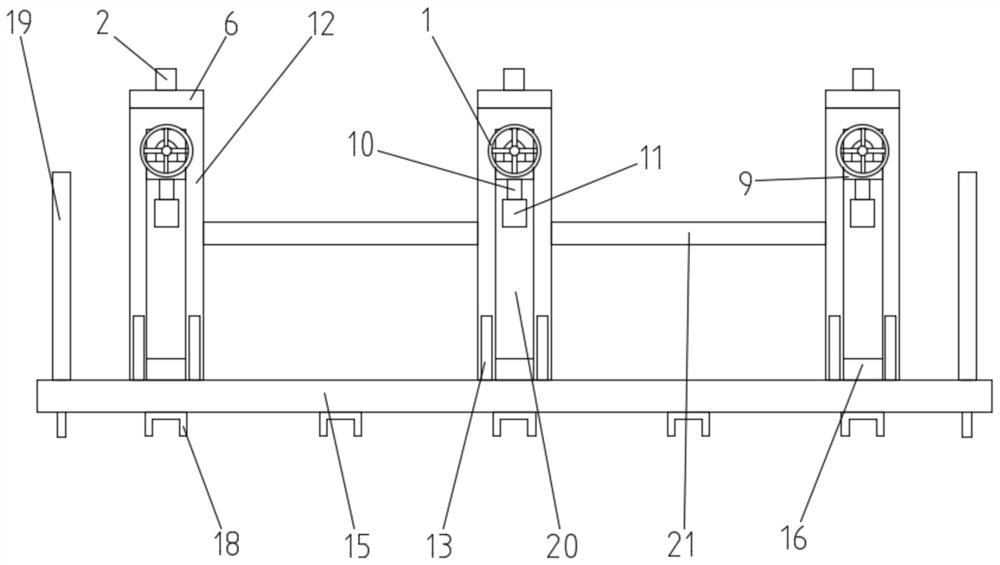

[0029] combined with Figure 2-3 Said port steel pipe stacking and handling crane stable lifting spreader includes a base plate 15 and a plurality of door frames fixed on the upper surface of the base plate 15 and arranged at intervals along the longitudinal direction of the base plate 15. The door frames are generally set to three , distributed at the two ends and the middle of the base plate 15; as required, the lower surface of the base plate 15 is longitudinally arranged with a plurality of reinforced channel steels 18, which can increase the bearing strength of the base plate 15, and can also facilitate forklift fork The door frame is composed of the flat frame plate 6 along the horizontal direction of the base plate 15 and the vertical frame plate 12 corresponding to the two plate surfaces to ensure the stability of the portal structure; as required, the two ends of the upper plate surface of the flat frame plate 6 Two lifting lugs 2 are fixed symmetrically for crane hoo...

Embodiment 2

[0035] The difference from Embodiment 1 is that the backing plate 16 is detachably installed on the upper surface of the base plate 15, the lower surface of the pressure plate 9 is provided with a T-shaped groove with a T-shaped cross-section and the end surface of the pressure plate, and the upper end of the suspender 10 The adapter is clamped in the T-shaped slot and can be moved and positioned in the T-shaped slot through the fastening bolt 22. When the diameter of the steel pipe changes, the steel pipe of the same specification can be adapted by replacing the crimping piece and the backing plate 16. However, due to the The width of the vertical frame plate 12 has been limited, and the thickness of the vertical frame plate 12 can be changed by installing a sub-plate on the inner surface of the vertical frame plate 12, thereby ensuring that the steel pipes close to the vertical frame plate 12 can be supported by resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com