Movable operation cabin structure

A mobile operation and operation cabin technology, applied in the field of rail transit, can solve the problems of potential safety hazards, only one operation cabin, and limited field of vision, and achieve the effects of ensuring safety, reducing work risks, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

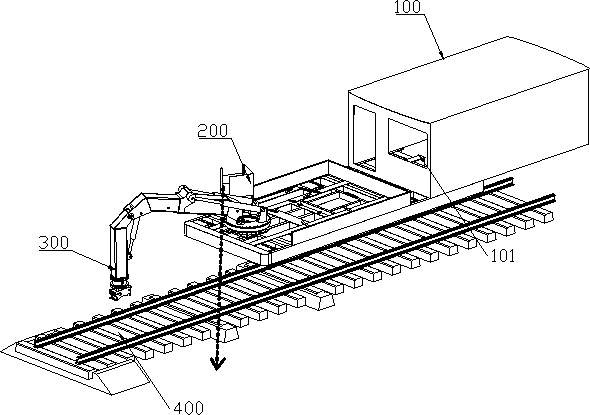

[0048] Such as Figure 3-Figure 9 As shown, the mobile operating cabin structure of this embodiment includes a base 1 located on the operating vehicle body, a supporting rotation mechanism and an operating cabin 10, wherein: the base 1 is provided with operating components, wherein the operating components can be mechanical arms 300 Components used for construction operations, etc., are described below using the mechanical arm 300 as an example. The peripheral wall of the base is provided with a guide rail 2; the operation cabin 10 is fixed on the support rotation mechanism, and the support rotation mechanism is movable along the guide rail 2, and the operation cabin 10 can be driven by the support rotation mechanism along the guide rail 2 by a mechanical arm. Rotate to the other opposite side of the arm and lock with base 1.

[0049] Wherein, the above-mentioned base 1 is the same as in the prior art, and it can be rotatably arranged on the work vehicle body to drive the mec...

Embodiment 2

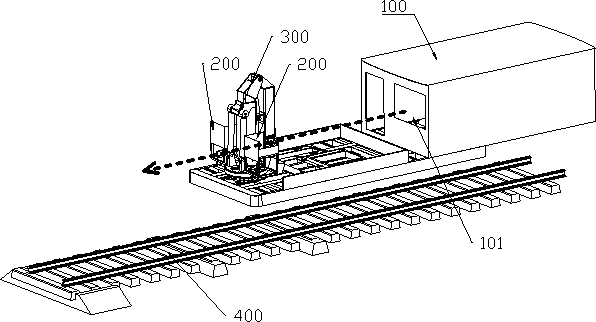

[0067]The first embodiment above provides a specific implementation manner in which the operation cabin 10 moves along the guide rail 2 , so that the operation cabin 10 can move from one side of the mechanical arm 300 to the other side on the base 1 . However, in order to operate the robot arm 300 conveniently, the front side of the operation cabin 10 should face the direction of the robot arm 300 . If the operation cabin 10 is only moved along the guide rail 2 from one side of the robot arm 300 to the other side, there may be a problem that the front side of the operation cabin 10 cannot face the direction of the robot arm.

[0068] In view of the above problems, this embodiment has been improved on the basis of the above-mentioned first implementation. The supporting and rotating mechanism of this embodiment also includes a self-rotating assembly, which is rotatably connected to the support frame 3 and connected to the operating cabin 10. So that the operating cabin 10 can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com