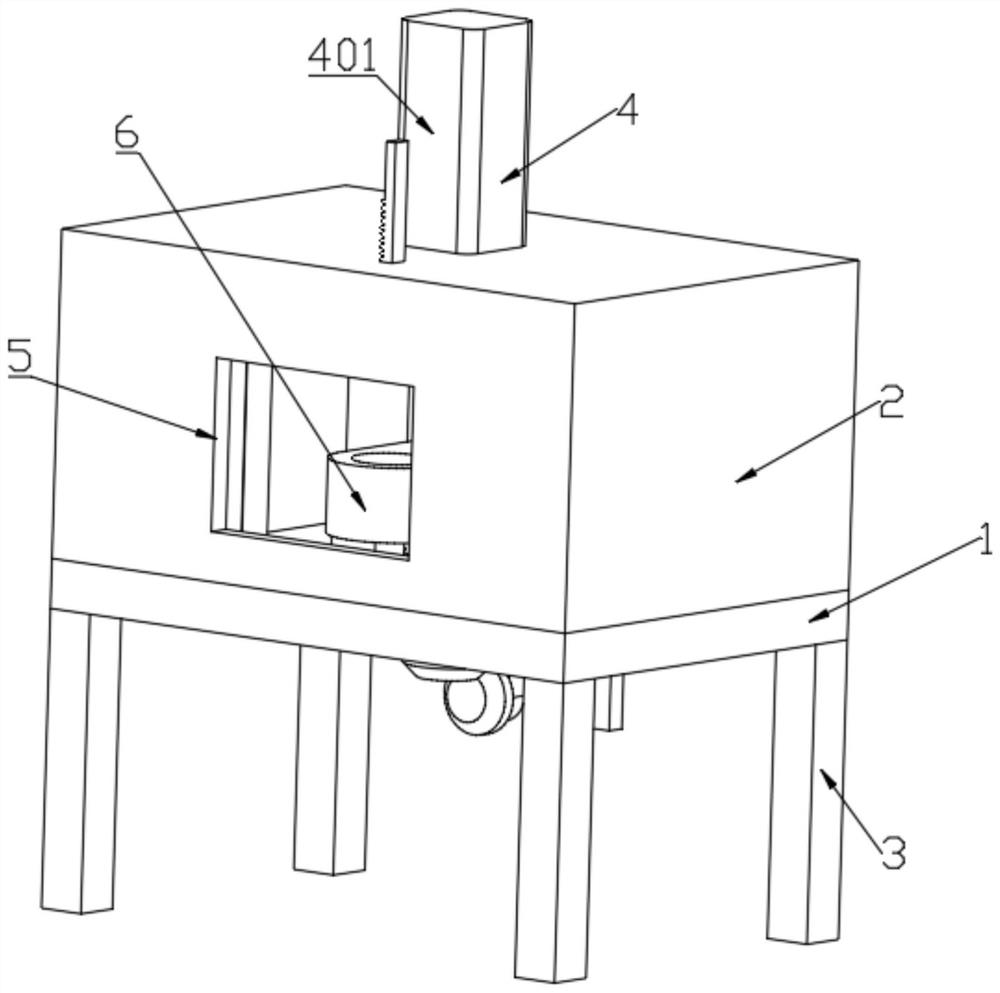

Safety device of stamping equipment and stamping equipment

A stamping equipment and safety device technology, applied in the field of stamping, can solve the problems of staff injury, plate splashing, no installation protection, etc., and achieve the effect of improving protection, preventing injury, and being easy to take

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

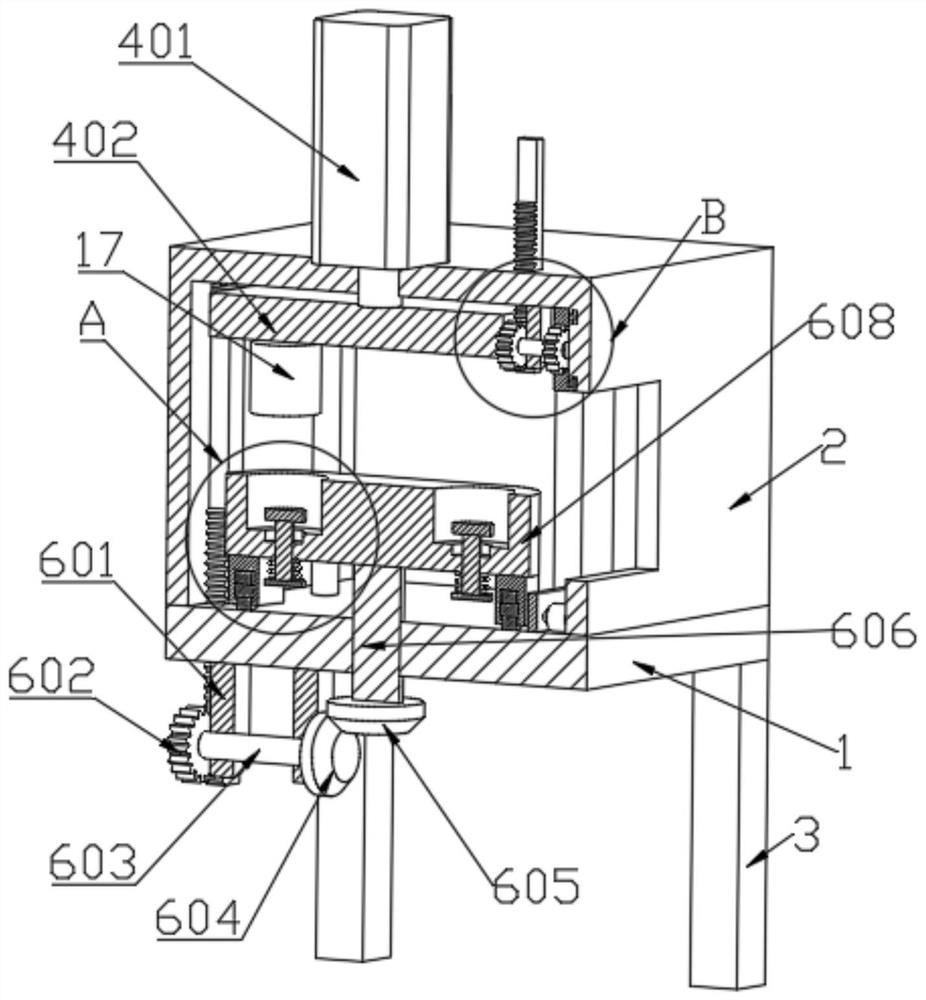

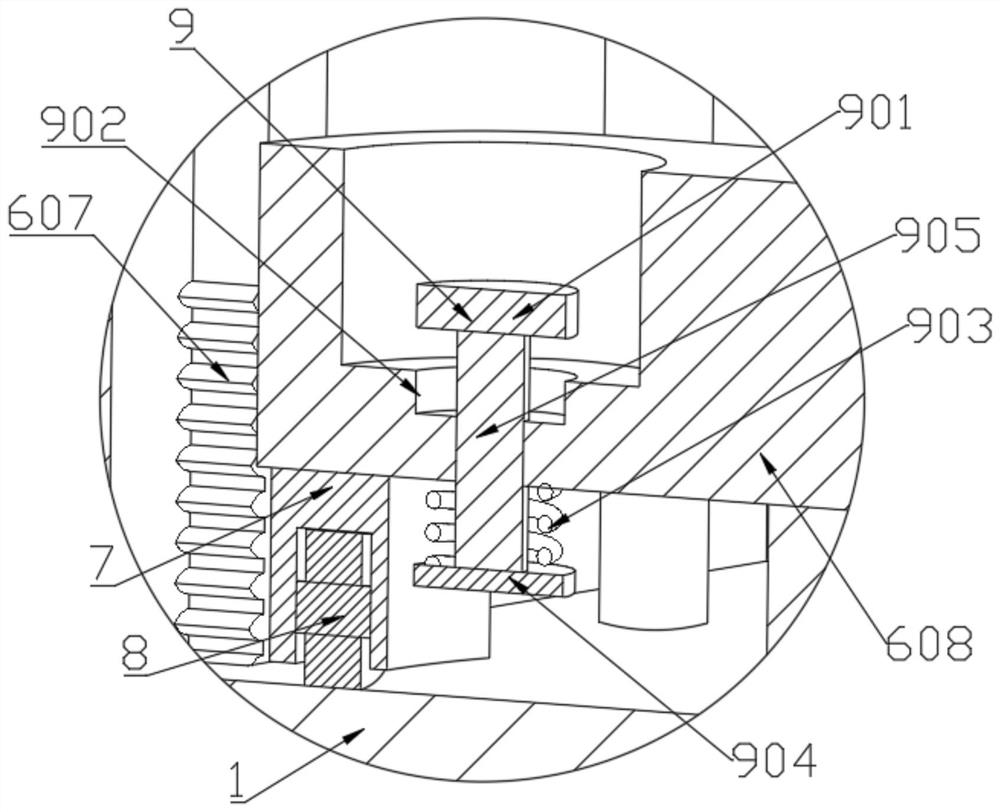

[0036] As a further embodiment of the present invention: the opening and closing device 10 includes a second rack 1004, a first gear 1002, a second rotating shaft 1003, a second gear 1004, a third rack 1005, an opening and closing door 1006, and a square groove 1007 And the second bearing seat 1008, the front end of the moving plate 402 is fixedly connected with the second rack 1004, the second rack 1004 is slidingly connected with the protective shell 2, the second rack 1004 is meshed with the first gear 1002, the first gear 1002 The front end is fixedly connected with a second rotating shaft 1003, the circumference of the second rotating shaft 1003 is fixedly connected with a second gear 1004, the second gear 1004 meshes with a third rack 1005, and the side end of the third rack 1005 is fixedly connected with an opening and closing door 1006. The front end of the opening and closing door 1006 is provided with an observation window 13 and a square groove 1007, and the square g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com