Heating and straightening device for metal rod

A technology for straightening metal rods, which is applied to metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high labor intensity, slow straightening speed, and troublesome operation of operators, so as to improve straightening processing efficiency and ensure The effect of straightening quality and preventing position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

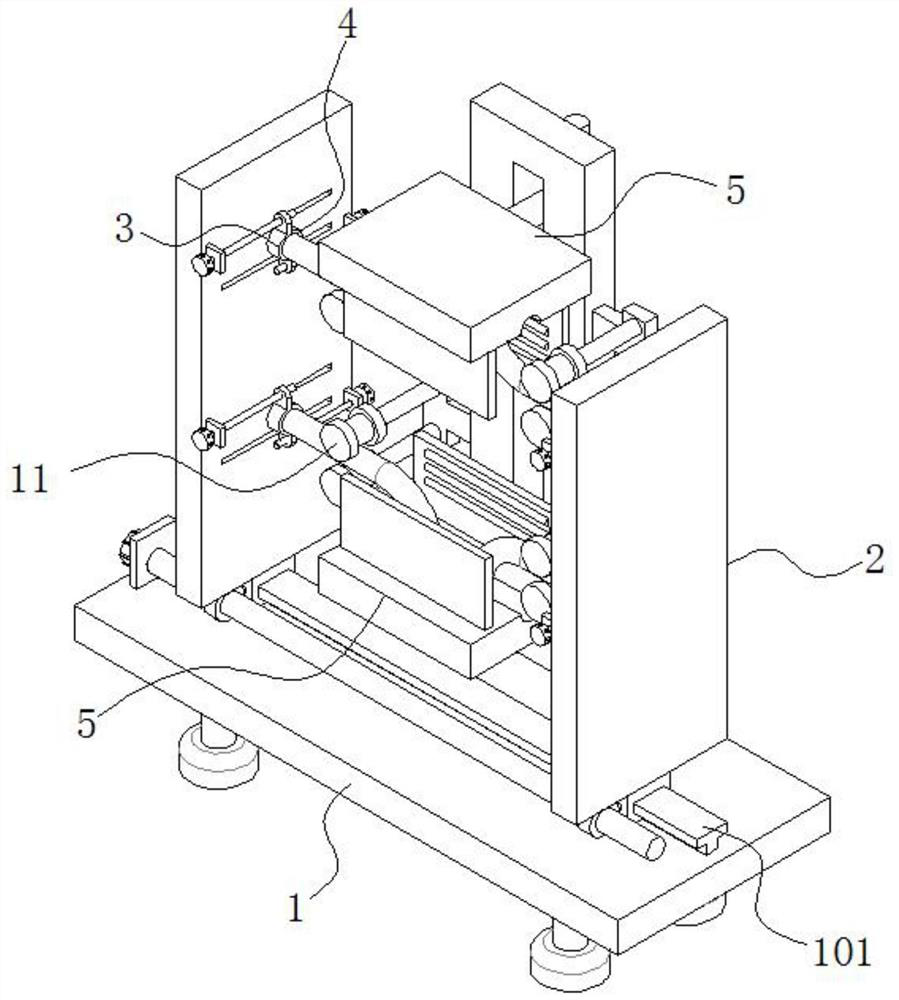

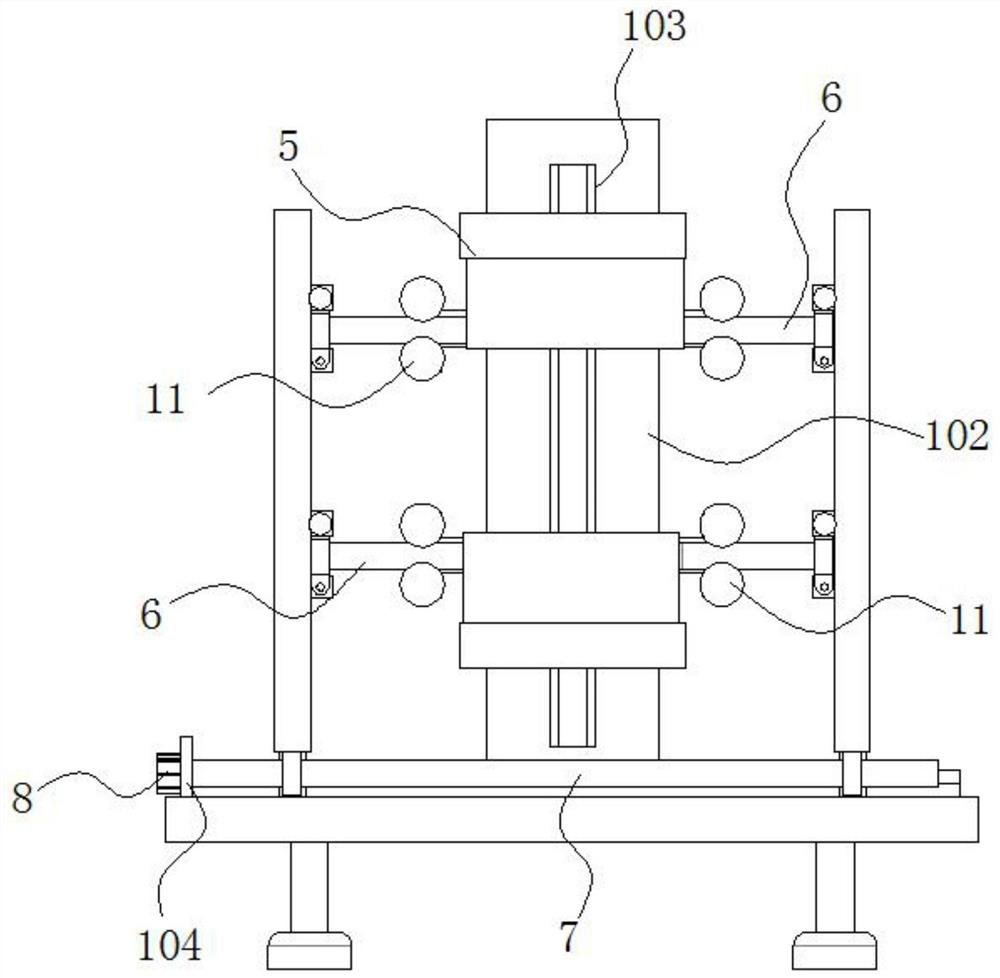

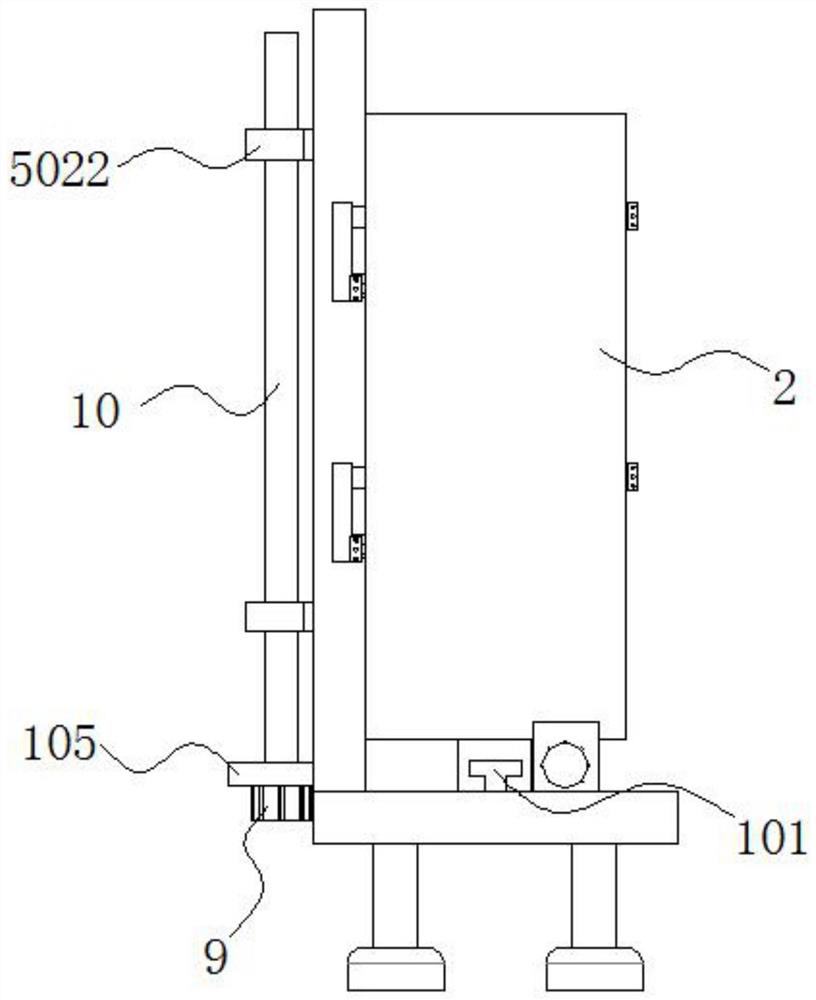

[0046] see Figure 1-2 and Figure 5-6 As shown, the present invention is a heating and straightening device for metal rods, including a base 1;

[0047] The upper surface of the base 1 is fixedly connected with a slide rail 101; the sides of the slide rail 101 are symmetrically slidably connected with two fixed tensile components 2;

[0048] Wherein, the fixed stretching assembly 2 includes a moving vertical plate 201; one side of the moving vertical plate 201 close to the center of the base 1 is respectively provided with two first limiting chute 202 and two second limiting chute 203;

[0049] The inside of the first limiting chute 202 is fixedly connected with the first clamping assembly 3 through the slider;

[0050] The inside of the second limiting chute 203 is fixedly connected with the second clamping component 4 through the slider; the second clamping component 4 is arranged in the opposite direction up and down with the first clamping component 3 ;

[0051] A slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com