Auxiliary process method for automatically stacking iron cores

A process method and automatic technology, applied in the direction of inductance/transformer/magnet manufacturing, magnetic core manufacturing, electrical components, etc., can solve the problems of inability to measure the diagonal distance, core stacking positioning deviation, inaccurate measurement, etc. Stable and reliable stacking quality, elimination of microwave errors, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are part of the embodiments of the present invention, not all of them.

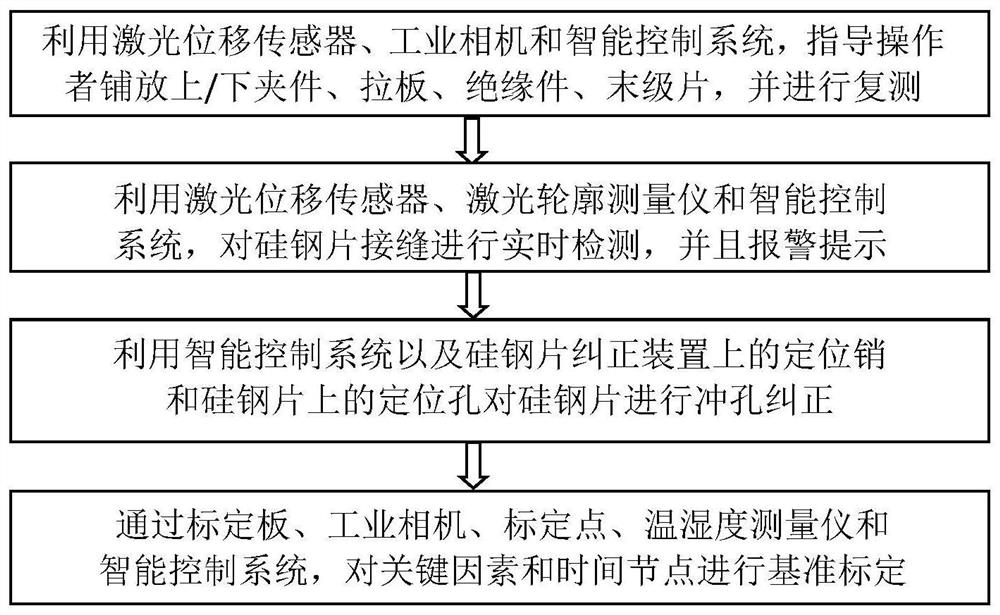

[0024] Such as figure 1 Shown is a logic flow diagram of the auxiliary process method of the embodiment of the present invention. An auxiliary process method for automatic stacking of iron cores, comprising the following steps:

[0025] Step 1. Before the automatic stacking process of silicon steel sheets starts, use laser displacement sensors, industrial cameras and intelligent control systems to guide the operator to lay the upper / lower clamps, pull plates, insulating parts, and final sheets, and lay them Retest after completion. Once it is in place, the placement is precise and the level is good.

[0026] The laser displacement sensor is a sensor that uses laser technology for measurement. It consists of a laser, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com