Portable small-tension yarn winding machine for large-core-number high-density micro-cluster optical cable

A high-density, large-core technology, applied in light guides, optics, optical components, etc., can solve the problems that are not suitable for multiple sets of bushings to be used at the same time, interfere with the walking path of each set of bushings, and have no pitch adjustment, etc., to achieve improved Production efficiency and casing identification and management capabilities, small footprint, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

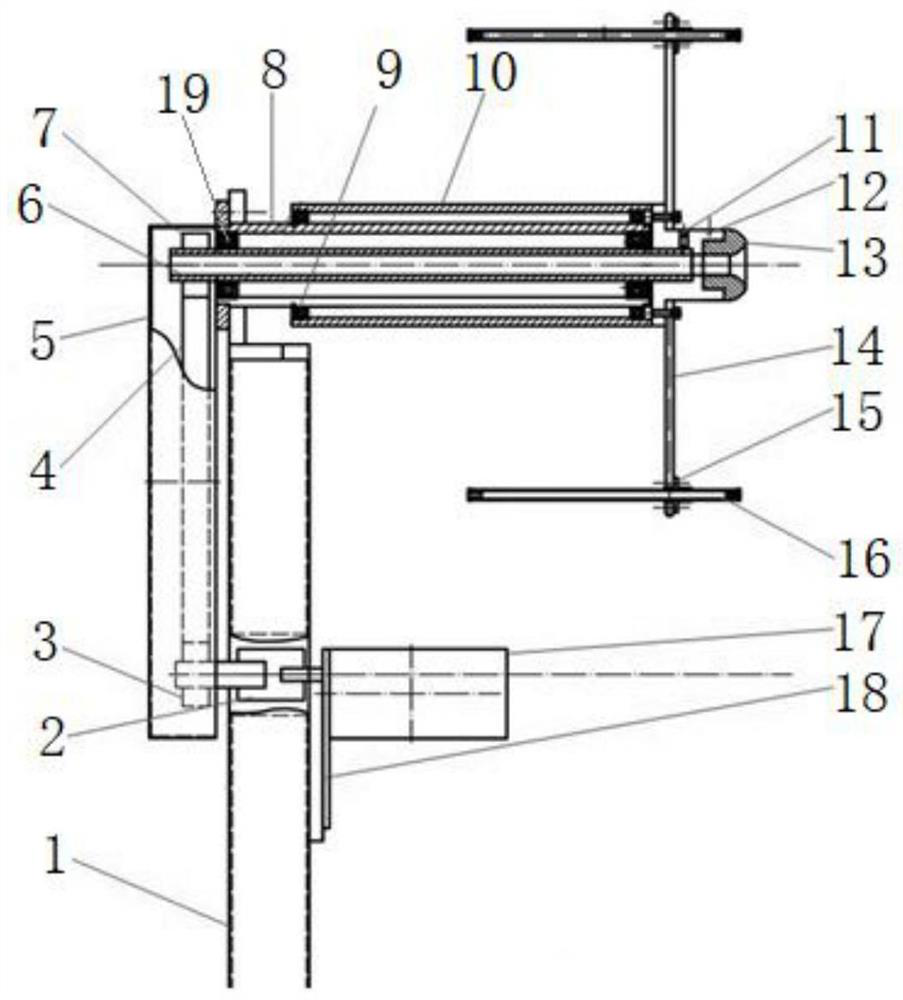

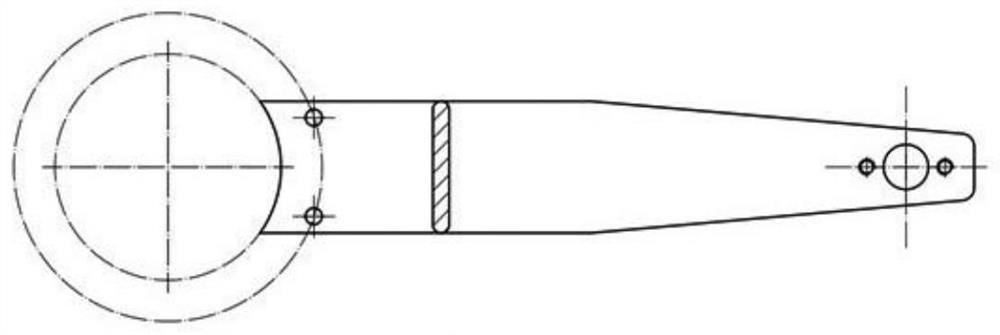

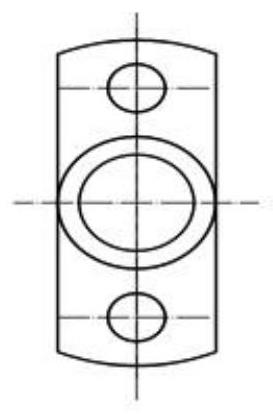

[0034] refer to figure 1 ~Figure 5, a portable small-tension yarn winding machine for large-core high-density micro-cluster optical cables, including frame 1, motor 17, support sleeve 8, central hollow tube 6, moving ring mold base 12, and bobbin shaft Cover 10, guide mold 13, shuttle 14 and yarn guide tube 16, wherein:

[0035] Both the motor 17 and the support sleeve 8 are installed on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com