Visual cement paste gelling strength monitoring device and method for retaining wall

A technology of gel strength and monitoring device, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of invisible process, support, lack of convincing experimental data, etc., to achieve simple and easy monitoring process, reduce cost increase, Accurate and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

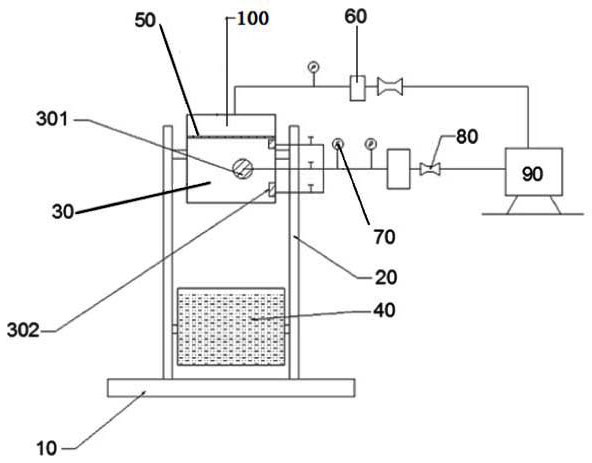

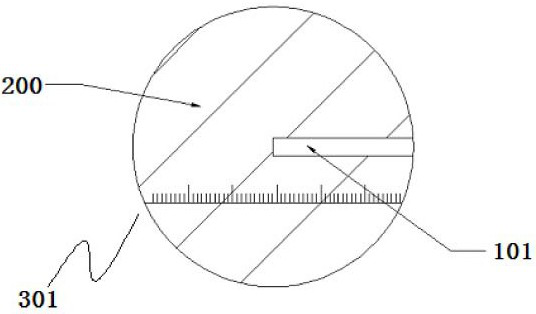

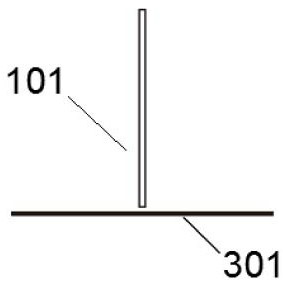

[0048] According to a preferred embodiment, when using the cement slurry gel strength monitoring device of the present invention, firstly, the cement slurry 200 to be tested is accommodated in the pressure chamber of the reactor body 30, so that it undergoes a coagulation and hardening reaction, and when it is necessary to measure When the gel strength of the cement slurry 200 is measured at each stage, according to the specific detection needs, the pressurized fluid 100 is injected into the first pressure chamber above the pressure chamber through the pressurized fluid pump unit to provide corresponding pressure to the pressure chamber containing the cement slurry 200. The pressure state of the formation, and the temperature state of the corresponding formation provided by the heating part 40 to the pressure chamber containing the cement slurry 200, after starting to measure, after the cement slurry 200 solidifies and hardens for a certain set time, start the booster pump 80 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com