Intelligent coal quality testing system

An intelligent, coal-quality technology, applied in material inspection products, instruments, measuring devices, etc., can solve the problems of increased assay cost, low assay efficiency, and poor use effect, and achieves reduced assay cost, high assay efficiency, and improved accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

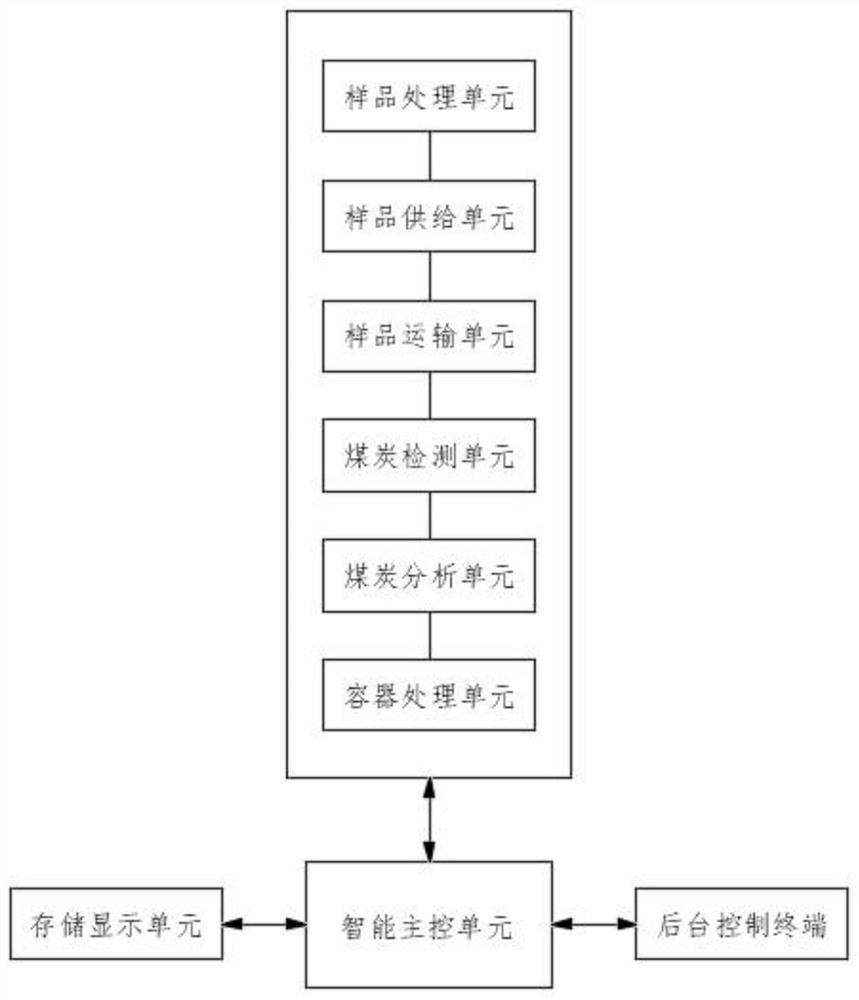

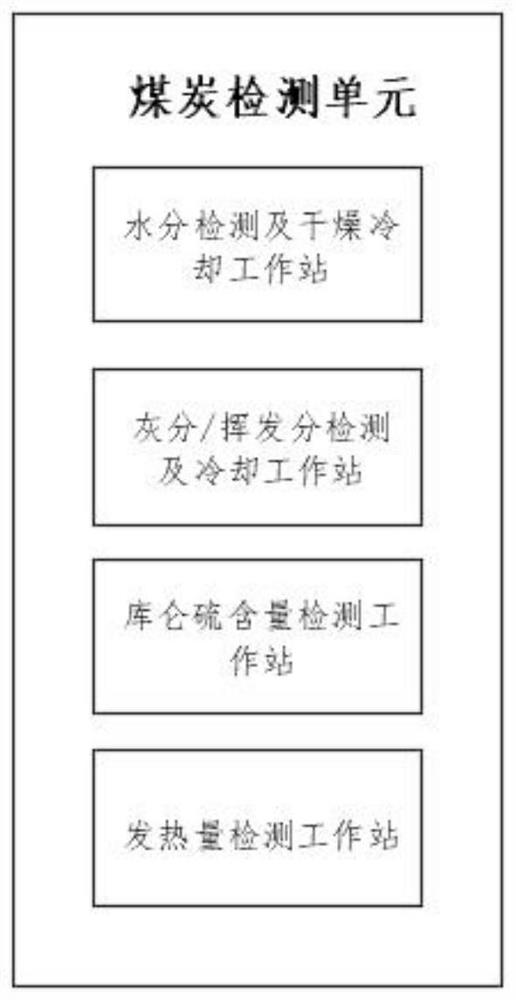

[0052] like Figure 1-4 As shown, the coal quality intelligent testing system proposed by the present invention includes an intelligent control unit, and the intelligent control unit communicates with the sample supply unit, sample transport unit, coal detection unit, coal analysis unit, container processing unit, storage display unit, The background control terminal is connected by communication to realize the control of each group of functional units and realize information transmission; the background control terminal is used to send control instructions to the intelligent control unit to remotely control the operation of each functional unit, and to receive coal detection data and analysis information and the operating status information of each functional unit, which is helpful for remote control;

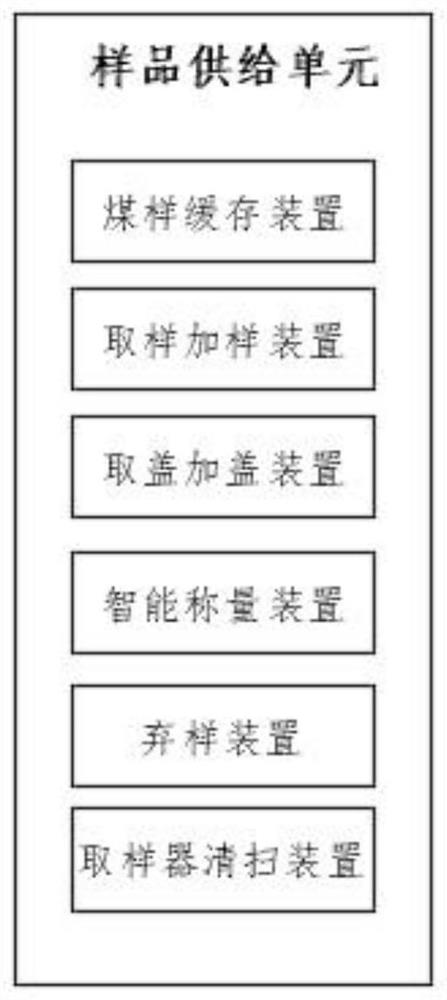

[0053] The sample supply unit is used to store coal samples and supply the required samples based on the weight requirements of various testing items; the sample supply unit i...

Embodiment 2

[0072] like Figure 5-7 As shown, the difference between this embodiment and Embodiment 1 is that the assay system also includes a sample processing unit, which is used to process the sample to make it meet the detection requirements, and the sample processing unit includes a collection and screening box 1 and a pulverization Box 2, collecting and screening box 1 is provided with a first collection chamber 3, a second collection chamber 4, a transmission belt 19 and a connecting block 21, the first collection chamber 3 and the second collection chamber 4 are separated by a vertical plate 5, and the vertical plate 5 is provided with an opening 6, and a slant plate 7 is installed in the first collection chamber 3, and a sieve plate 8 is fixed on the slant plate 7 by bolts, and the slant plate 7 is inclined downward toward the direction of the opening 6; the sieve plate 8 pairs fall The samples are screened, the bottom of the first collection chamber 3 collects the qualified samp...

Embodiment 3

[0077] like Figure 8 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the connecting column 22 includes a connecting rod 221, a fixed cylinder 222, a guide rod 223, a protrusion 224 and a spring 225, and the fixed cylinder 222 is fixedly connected to the connecting block 21 , the connecting rod 221 is connected with the rubber ball 23, and the end of the connecting rod 221 away from the rubber ball 23 is inserted into the fixed cylinder 222, the fixed cylinder 222 is provided with a guide rod 223, the number of the guide rod 223 is multiple groups, and the protrusion 224 is arranged on The connecting rod 221 is located in the fixed cylinder 222, and the number of the protrusions 224 is multiple groups and is slidably connected with the corresponding guide rod 223. The spring 225 is sleeved on the outer peripheral surface of the guide rod 223, and the spring 225 is connected with the protrusion 224. , during the rotation process of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com