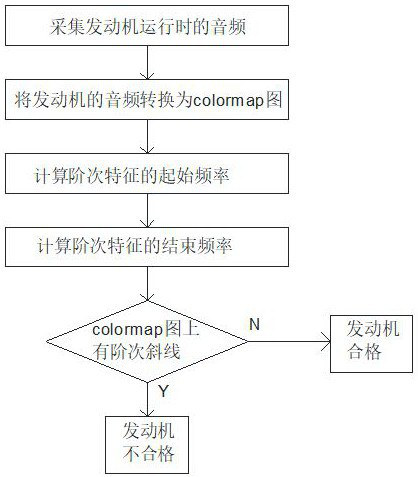

Engine gear howling noise identification method

An identification method and engine technology, which is applied in the direction of engine testing, machine/structural component testing, internal combustion engine testing, etc., can solve the problems that cannot be used to judge engine gear whistling, different noise frequencies, and complicated processing processes, so as to avoid The effect of manual recognition is large, avoiding high misjudgment rate, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1: After the production of the engine comes off the assembly line, the audios of 100 assembled engines are sequentially collected in the test room. The numbers are 1#, 2#, ..., 100#. There are three processes of 10s in the speed condition, 10s in the steady running condition and 10s in the reduced speed condition.

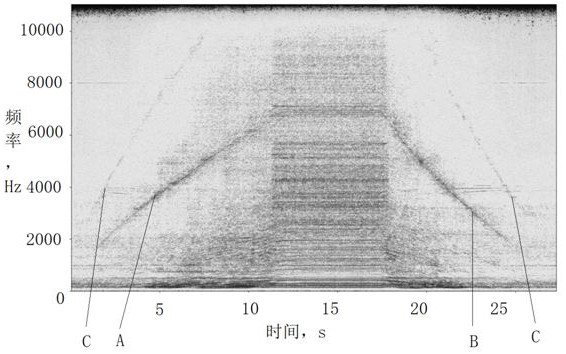

[0043] Step 2: Convert the audio of the engine numbered 1# into a colormap through short-time Fourier transform, as shown in the attached figure 2 shown. The horizontal axis of the colormap graph is time (s), and the vertical axis is frequency (Hz).

[0044] Step 3: Manually identify the order features on the colormap.

[0045] The number of gear teeth of the 1# engine is 100, so the order of the problem is 100, that is, n≈100. The idle speed of the engine is w1=700rpm, and the rated speed is w2=4100rpm.

[0046] Step 3.1: Calculate the starting frequency f1=w1 / 60*n≈1167Hz of the order feature.

[0047] Step 3.2: Calculate the end frequency f2=w2 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com