A single-atom zinc material that can replace zinc oxide used in the rubber field and its preparation method

A zinc oxide and atom technology, applied in the field of rubber additives, can solve the problems of high zinc oxide content and waste of zinc resources, and achieve the effects of ensuring driving safety, prolonging service life and reducing residual pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

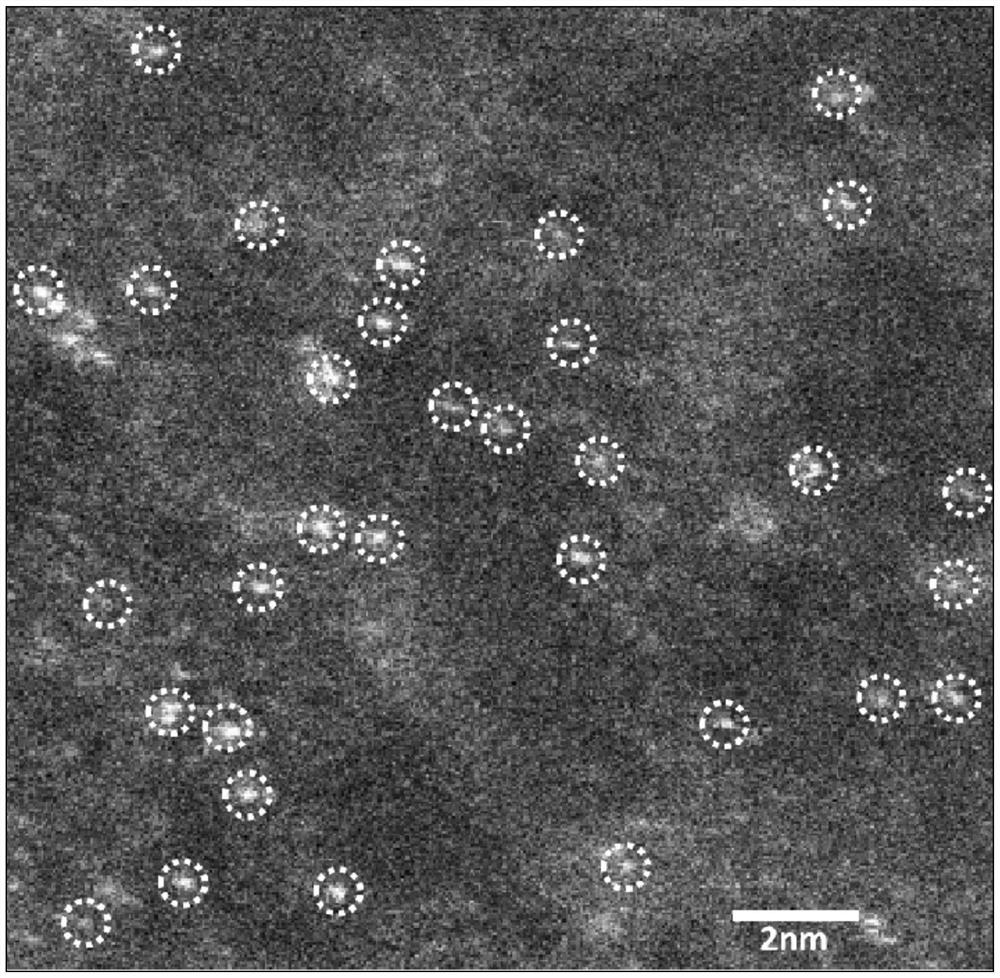

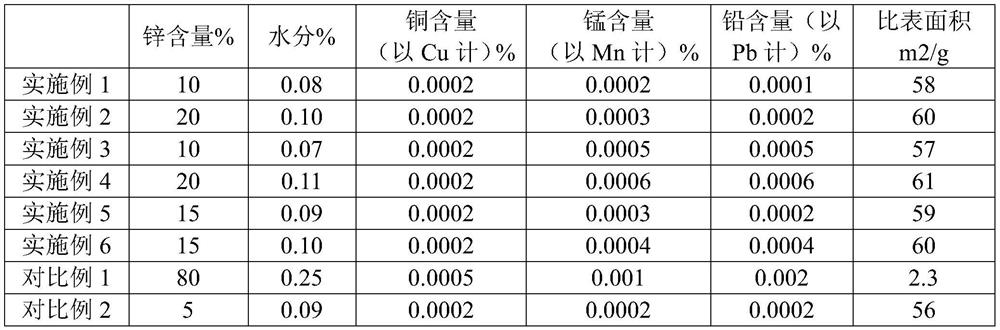

[0038] refer to figure 1 , is a single-atom zinc material that can replace zinc oxide in the rubber field disclosed in this application. The single-atom zinc material is composed of a carrier and a transition metal. The carrier is 100nm nano-silicon dioxide, the transition metal is zinc, and the zinc Atoms are anchored on defect sites on the surface of the carrier in the form of single atoms, and the mass ratio of single-atom zinc to nano-silicon dioxide is 1:10.

[0039] A method for preparing a single-atom zinc material that can replace zinc oxide used in the rubber field, comprising the following steps:

[0040] (1) Add 500nm nano-silica to a planetary ball mill for ball milling, the ball milling speed is 450rpm, and the ball milling time is 30min, at this time the carrier particle size is 100nm, ready for use;

[0041] (2) Weigh 1000g of the 100nm nano-silica carrier in step (1), add it to 1L of 1mol / L sodium hydroxide aqueous solution, control the rotation speed at 1000r...

Embodiment 2

[0045]The difference between embodiment 2 and embodiment 1 is:

[0046] A method for preparing a single-atom zinc material that can replace zinc oxide used in the rubber field, comprising the following steps:

[0047] (1) Add 500nm nano-silica to a planetary ball mill for ball milling, the ball milling speed is 450rpm, and the ball milling time is 30min, at this time the carrier particle size is 100nm, ready for use;

[0048] (2) Weigh 1000g of the 100nm nano-silica carrier in (1), add it to 1L of 1mol / L sodium hydroxide aqueous solution at a speed of 1000rpm, raise the temperature to 80°C, and fully react for 36h. Construct sufficient defect sites, then filter, dry, and fully grind with an agate mortar for 20 minutes, and set aside;

[0049] (3) Mix the carrier modified in (2) with a zinc nitrate solution with a zinc ion content of 200g / L, heat up to 60°C, stir thoroughly for 24h, remove the supernatant, centrifuge, and place at 120°C Dried in a blast drying oven for 12 hou...

Embodiment 3

[0052] The difference between embodiment 3 and embodiment 1 is:

[0053] A method for preparing a single-atom zinc material that can replace zinc oxide used in the rubber field, comprising the following steps:

[0054] (1) Add 500nm nano-silica to a planetary ball mill for ball milling, the ball milling speed is 450rpm, and the ball milling time is 30min, at this time the carrier particle size is 100nm, ready for use;

[0055] (2) Weigh 1000g of the 100nm nano-calcium carbonate carrier in (1), add it to 1L of 1mol / L sodium hydroxide aqueous solution at a speed of 1000rpm, heat up to 80°C, and fully react for 36 hours to build sufficient defects on the surface of the carrier site, then filtered, dried, fully ground, and set aside;

[0056] (3) Mix the carrier modified in (2) with a zinc nitrate solution with a zinc ion content of 100g / L, heat up to 60°C, stir thoroughly for 24h, remove the supernatant, centrifuge, and place at 120°C Dried in a blast drying oven for 12 hours. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com