UHPC suitable for long-term sewage environment and preparation process thereof

An environmental and sewage technology, applied in the field of anti-corrosion of building materials, can solve the problems of insufficient protection of steel bars, UHPC erosion, structural damage, etc., and achieve long-term resistance to microbial corrosion, good biological corrosion, and increased fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a kind of UHPC suitable for long-term sewage environment and its preparation process. The components of UHPC are as follows in terms of mass ratio: water, cement, quartz sand, high activity mineral admixture, low activity joint filler, steel The mass ratio of fiber, high-performance polycarboxylate water reducer, ether emulsion defoamer and antibacterial agent phthalocyanine blue is 0.250:1:1.55:0.30:0.10:0.235:0.0133:0.00224:0.005; wherein cement includes mass P·O52.5 ordinary Portland cement and P·O52.5 calcium aluminate cement with a ratio of 1:0.06.

[0037] Its preparation process comprises the following steps:

[0038] S1. Add cement, fine aggregate, high-activity mineral admixture and low-activity joint filler into the mixer according to the above mass ratio, and pre-mix for 2 minutes;

[0039] S2, water reducer, defoamer and antibacterial agent are added in the mixture of step S1 according to the above ratio and stirred for 1min, then a...

Embodiment 2-5

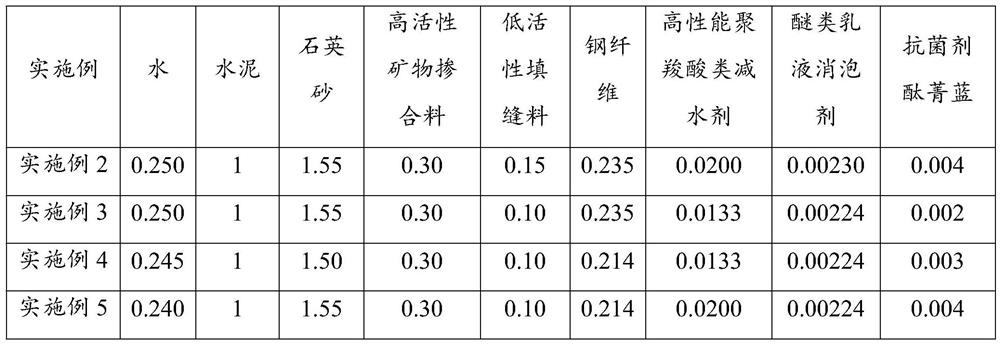

[0053] Embodiment 2-5 provides a kind of UHPC applicable to long-term sewage environment and its preparation process. Compared with Embodiment 1, the difference is that the orthogonal experiment design method is adopted, and the components of UHPC are counted according to the mass ratio as shown in the following table , and the rest are substantially the same as those in Embodiment 1, and will not be repeated here.

[0054] Table 2 Example 2-5 prepares UHPC composition table

[0055]

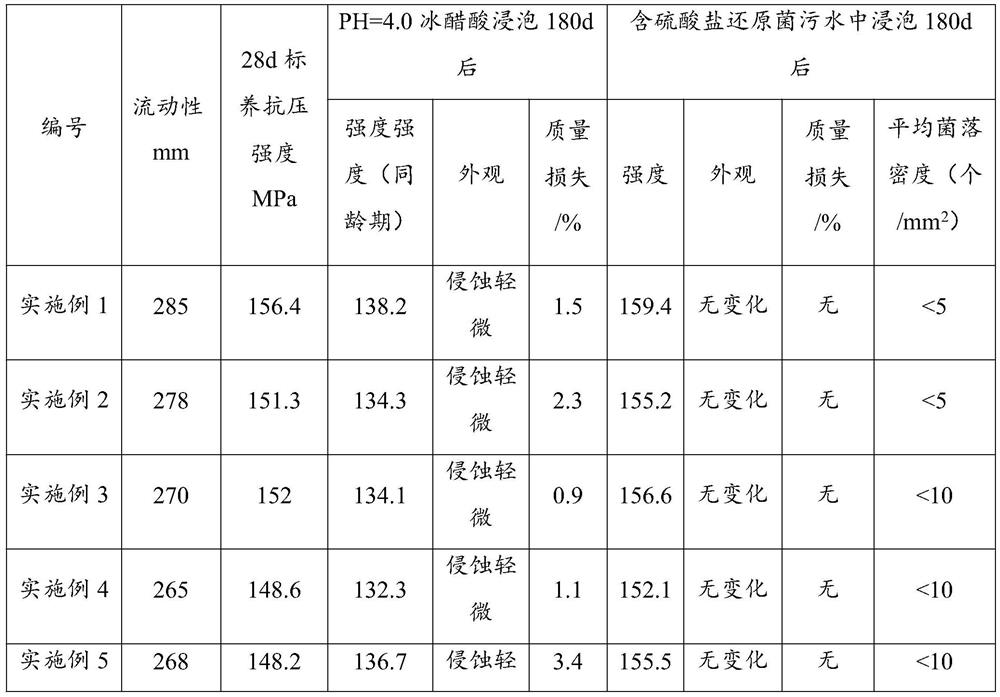

[0056] Using the same method as above, the performance of the UHPC obtained in Examples 2-5 is tested, and the test results are shown in the following table.

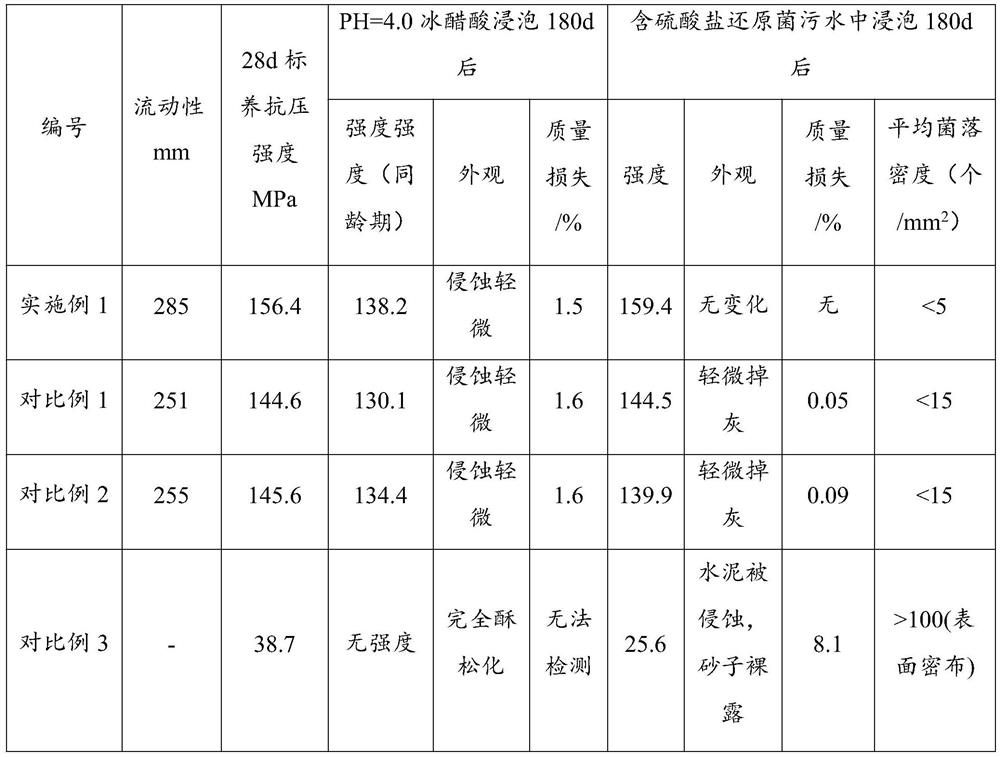

[0057] The test result of table 3 embodiment 1-5 and comparative example 1 gained UHPC

[0058]

[0059]

[0060] It can be seen from Table 3 that the raw material components are inconsistent, and the fluidity and strength of the obtained UHPC are inconsistent, but the strength of the UHPC of all examples after soaking in sewage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com