Efficient water treatment flocculant and preparation method thereof

A technology for water treatment and flocculant, which is applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Achieve sustainable development, improve flocculation effect and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]A high-efficiency water treatment flocculant, which is composed of polyaluminum chloride and polysilicic acid, and its preparation method is as follows:

[0046] S1, add polyaluminum chloride to polysilicate, stir at 20°C for 10 minutes, then raise the temperature to 26°C, and continue stirring for 8 minutes to obtain a premix;

[0047] S2, aging the premixed solution at 30° C. for 5 hours to obtain.

[0048] It has been determined that in the high-efficiency water treatment flocculant prepared in this example, Al:Si=0.5:1 calculated by molar ratio.

[0049] In this embodiment, polyaluminum chloride is commercially available liquid polyaluminum chloride, Al 2 o 3 The content is 10%;

[0050] Polysilicic acid is a commercially available polysilicic acid flocculant, SiO 2 The content is 2.5%.

Embodiment 2-5

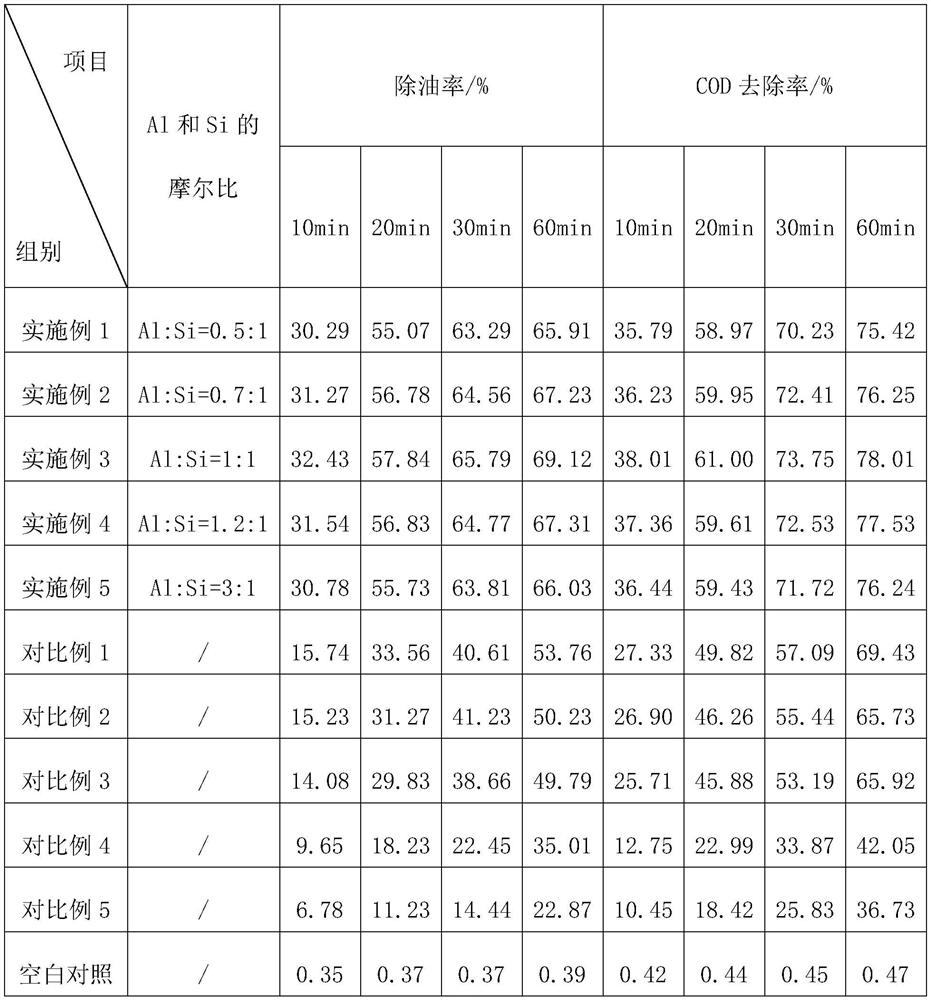

[0052] A high-efficiency water treatment flocculant differs from Example 1 in that the molar ratio of Al and Si in the high-efficiency water treatment flocculant is different, as shown in Table 1 for details.

Embodiment 6

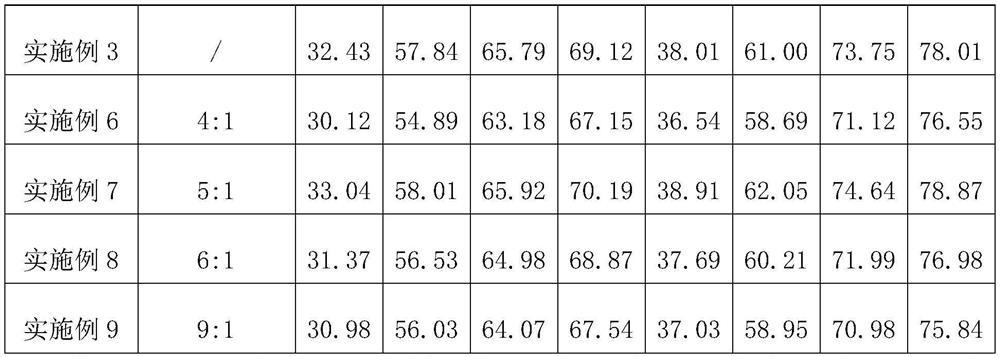

[0069] A high-efficiency water treatment flocculant, the difference from Example 3 is that both polyaluminum chloride and polysilicic acid are self-made.

[0070] The preparation method of polyaluminum chloride is as follows: mix aluminum foil acid and calcium aluminate powder at a weight ratio of 4:1, and stir and mix evenly at 90°C to obtain the product.

[0071] After measurement, the salinity of the polyaluminum chloride prepared in this embodiment is 50.70%, Al 2 o 3 The content is 10.09%.

[0072] The preparation method of polysilicic acid is: mix sodium silicate and deionized water to obtain a mixed solution, and control the SiO in the mixed solution 2 content of 2%, then add hydrochloric acid with a mass concentration of 5% to adjust the pH to 4, and keep the temperature at 20°C for 30 minutes to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com