Heavy-load bidirectional storing and taking carrying device and double-rail heavy-load stacking machine

A two-way access and stacker technology, applied in the direction of lifting devices, lifting frames, etc., can solve the problems of unsolved heavy-duty stacker volume, reduced work efficiency and stability, self-heavy, etc., to reduce the complexity of transmission, Introduction to the transmission route and the effect of reducing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

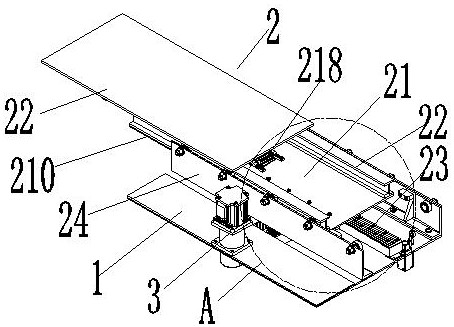

[0050] Example 1. Such as Figure 1-12 As shown, a heavy-duty two-way access loading device includes a lifting frame 1 and a two-way access cargo platform 2, and is characterized in that: the lifting frame 1 is provided with an access drive motor 3, and the two-way access cargo platform 2 Installed on the lifting frame 1.

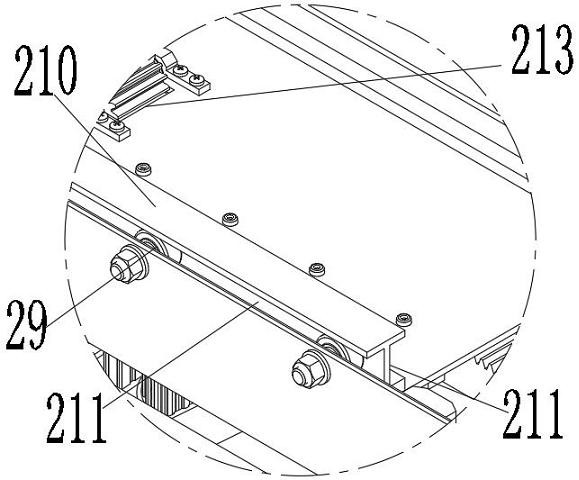

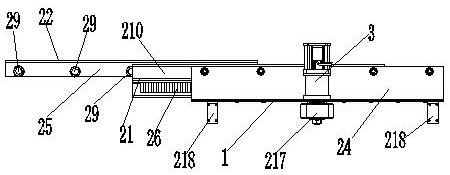

[0051] The two-way access cargo platform 2 includes a middle board 21, an upper board 22, a lower rack 23, two first vertical boards 24, two second vertical boards 25, side racks 26, a driving gear 27, and a driven gear 28. Lifting frame 1 is vertically provided with the lower tooth bar 23 that tooth surface faces up, and the left and right sides of lower tooth bar 23 are respectively provided with the first vertical board 24 that is perpendicular to lifting frame 1 longitudinally, each first vertical board The 24 top is provided with some first rollers 29 whose top surface is parallel to the top surface of lifting frame 1 near the other first vertical pl...

Embodiment 2

[0066] Example 2. Such as Figure 13 As shown, the heavy-duty two-way access loading device includes a lifting frame 1 and two two-way access cargo platforms 2. The lifting frame 1 is provided with an access drive motor 3, and the left and right sides of the access drive motor 3 are arranged on the lifting frame 1. Each of the two sides is provided with any one of the two-way access cargo platforms 2; the access drive motor 3 is connected to the driving gear 27 of the two two-way access cargo platforms 2. In this technical solution, only one access drive motor 3 is used to drive two bidirectional access cargo platforms 2, which has the advantages of stronger loading capacity and better synchronization.

[0067] Two two-way access cargo platforms 2 are arranged symmetrically along the access drive motor 3 .

Embodiment 3

[0068] Example 3. Such as Figure 14-27 As shown, the double-track heavy-duty stacker includes a pair of longitudinal guide rails composed of two symmetrically arranged longitudinal guide rails 4. The pair of longitudinal guide rails is provided with a horizontal frame 5 that can move longitudinally thereon. The front and rear sides of the horizontal frame 5 Each column 6 is provided in the middle of the end; a lift frame 7 is provided at the same height of each column 6, and the lift frame 1 and the two-way access cargo platform 2 of embodiment 1 are connected between the two lift frames 7;

[0069] The front and back two ends of the left end of the horizontal frame 5 are provided with the left transverse roller 41 that can run on the longitudinal guide rail 4 on the left side of the longitudinal guide rail, and the front and rear ends of the horizontal frame 5 are provided with the left horizontal roller 41 that can be moved on the longitudinal guide rail pair. The right ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com