Separated arrangement type hydraulic pipe fixing device

A technology of fixing device and hydraulic pipe, applied in the field of shelf storage, can solve the problems of deformation of hydraulic pipe, easy appearance of wear and tear, affecting the quality of hydraulic pipe, etc., to achieve the effect of ensuring a new level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

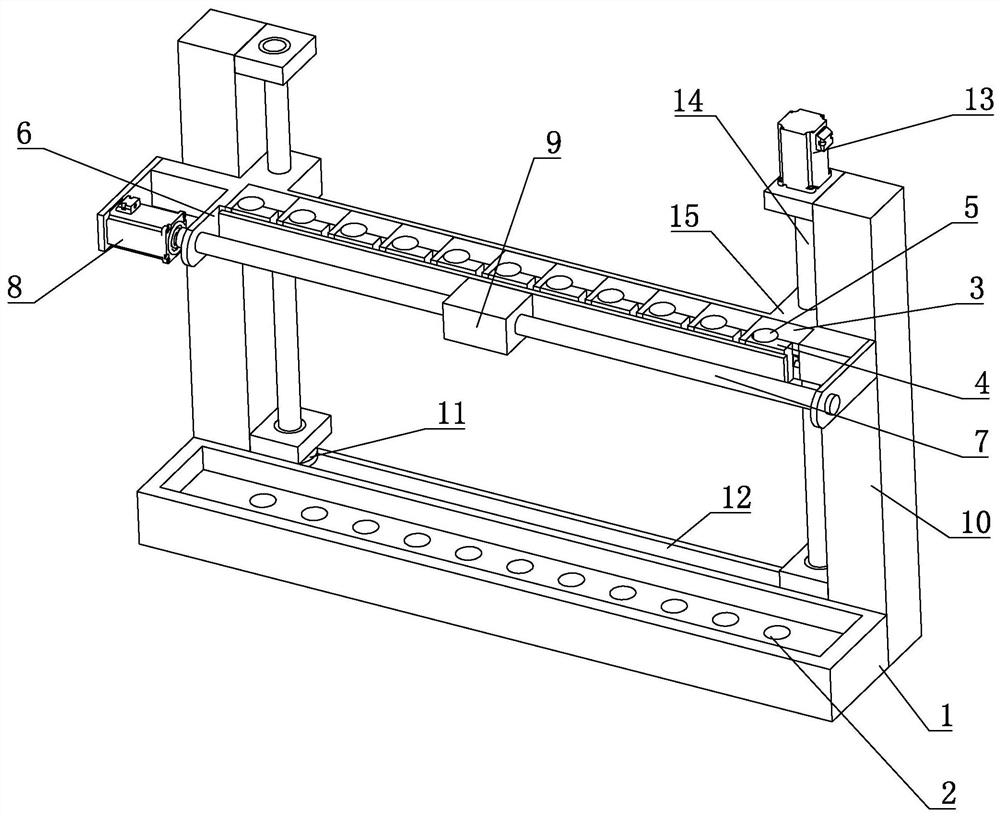

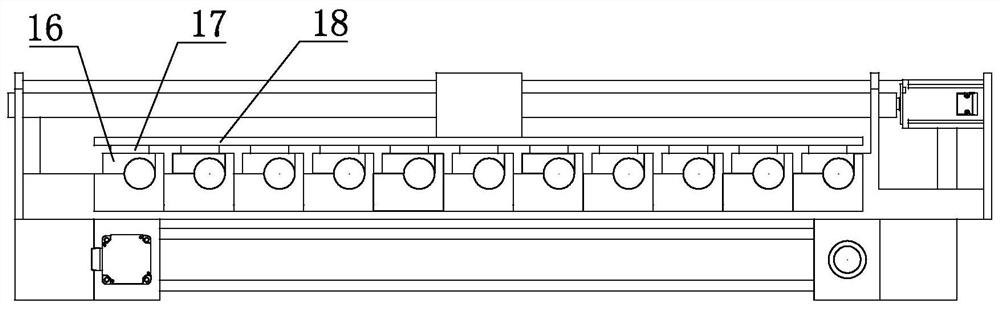

[0019] Embodiment 1: A separate and arranged hydraulic pipe fixing device, including a base 1, the top surface of the base 1 is in a downwardly recessed structure, and the surface of the base 1 is provided with eleven sets of pipe fitting fixing holes 2 arranged at equal intervals, each The dimensions of the two pipe fitting fixing holes 2 are the same, and the base 1 is a supporting part for placing the hydraulic pipe. The hydraulic pipe enters the pipe fitting fixing hole 2, and the bottom is initially fixed.

[0020] The top of the base 1 is provided with a clamping mechanism, and the clamping mechanism includes a fixed plate 3 and a movable splint 4. The side of the fixed plate 3 facing the movable splint 4 is provided with clamping notches 5 arranged at equidistant intervals. The movable splint 4 works together. When the fixed plate 3 and the movable splint 4 are installed in place, the two together form a circular closed space. The size of the closed space is consistent w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com