Silencer, compressor and air conditioner

A muffler and compressor technology, applied in the field of compressors, can solve the problems of high compressor oil discharge rate, low compressor oil pool oil level, insufficient lubrication of pump body components, etc., to ensure lubrication and oil discharge rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

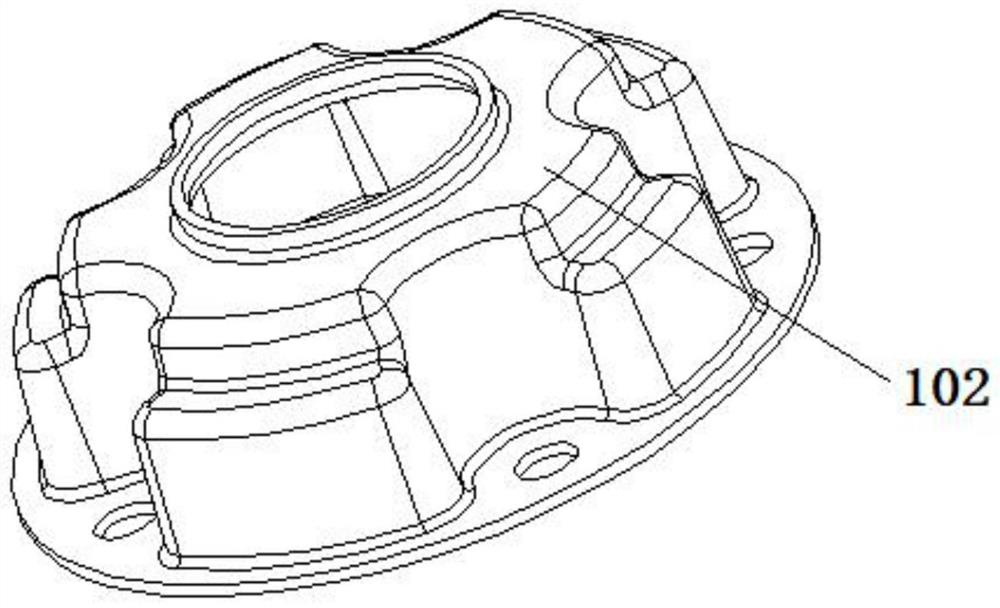

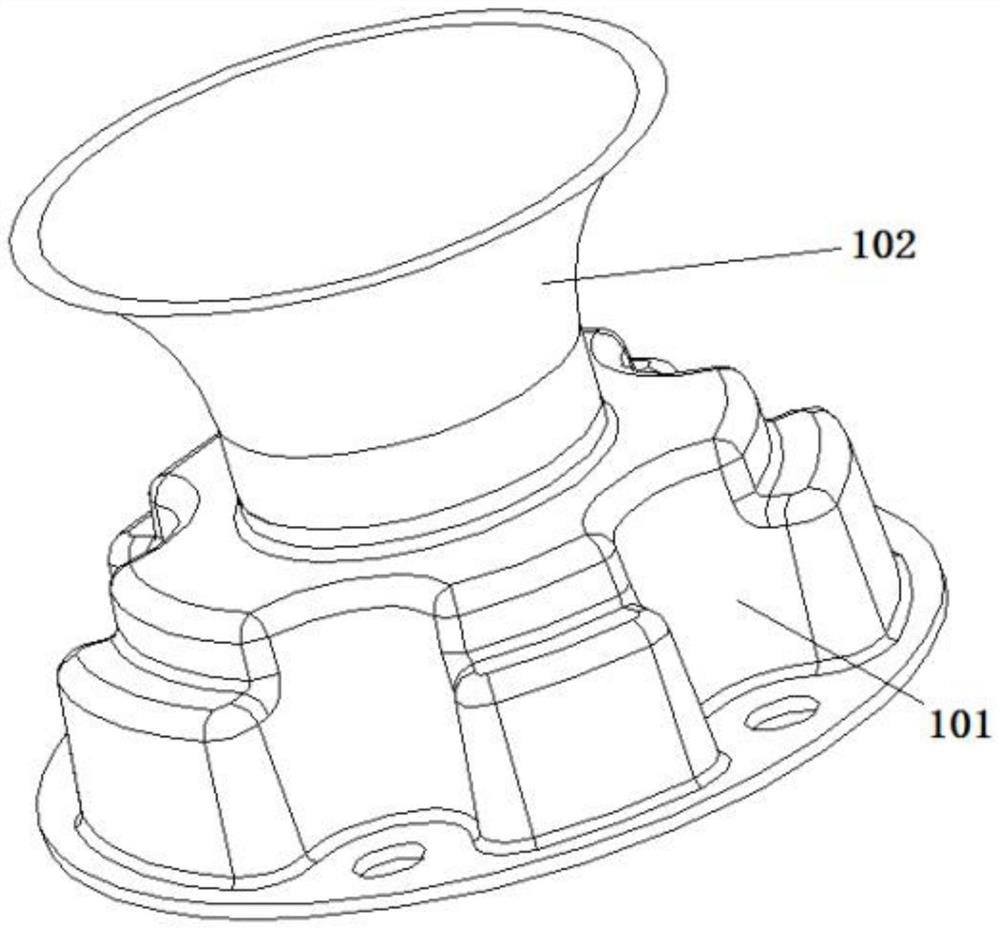

[0038] This embodiment provides a muffler, such as image 3 As shown, for a compressor, the muffler includes a sound absorbing assembly 101 and an oil retaining assembly 102, the oil retaining assembly 102 is arranged on the sound absorbing assembly 101, and the oil retaining assembly 102 divides the lower chamber of the compressor into a first chamber and a second chamber. cavity;

[0039] Specifically, after the above-mentioned structure is adopted, the refrigerating oil enters the first cavity, and under the action of the high-pressure gas discharged from the noise reduction assembly 101, enters the upper cavity of the compressor through the rotor flow hole of the compressor, and is sequentially It enters the second cavity through the stator winding gap of the compressor; at this time, due to the setting of the oil retaining assembly 102, most of the high-pressure gas is located in the first cavity, and the refrigerated oil in the second cavity will not be affected by the h...

Embodiment 2

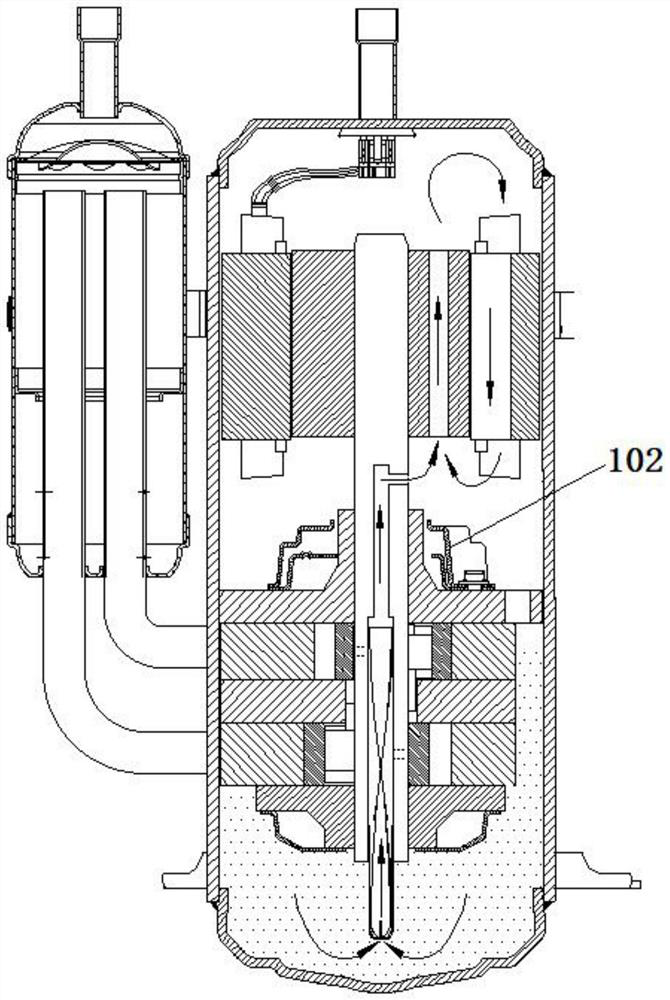

[0062] This embodiment provides a compressor, as shown in Figure 7 and Figure 8 As shown, the compressor includes the muffler 100, the pump body 200, the concentrated winding motor 300, the crankshaft 400 and the housing 500 in Embodiment 1, and the muffler 100, the pump body 200, the concentrated winding motor 300 and the crankshaft 400 are all located in the casing 500; the lower cavity 600 is formed between the pump body 200 and the concentrated coil motor 300, the muffler 100 is located in the lower cavity 600, and the upper cavity 700 is formed between the concentrated coil motor 300 and the housing 500; the crankshaft 400 is provided with an oil guide 401, the outlet of the oil guide member 401 communicates with the pump body 200 and the lower cavity 600;

[0063] The concentrated winding motor 300 includes a stator 301 and a rotor 302 that are arranged in cooperation. The rotor 302 is provided with a rotor flow hole 3021 , and a stator winding gap 3011 is formed betwee...

Embodiment 3

[0073] This embodiment provides an air conditioner, and the air conditioner includes the compressor of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com