Preparation method and application of amphiphilic graphene oxide thick oil viscosity reducer

A technology of olefin heavy oil and viscosity reducer, which is applied in the field of preparation of amphiphilic graphene oxide heavy oil viscosity reducer, can solve the problems of high cost of oil-soluble viscosity reducer, limited external shear force, environmental impact, etc. Achieve the effects of long-lasting viscosity reduction effect, low cost, and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Get 1g of graphene oxide (GO) and disperse it in 100mL of deionized water, and then use ultrasonic shear (30kHz) to process it for 2h to obtain GO nano-dispersion A (average particle size is 200nm), and the average particle size should not exceed 300nm, Otherwise, precipitation will easily occur in the subsequent modification process;

[0053] (2) Weigh 0.01g of octadecylamine and 0.01g of dodecylamine into 100mL of kerosene, and use magnetic stirring (300rpm, 10min) to mix the two evenly to obtain solution B;

[0054] (3) Pour 50mL of solution A into the beaker, then add 0.01g of silane coupling agent (KH550), stir magnetically at 70°C (300rpm, 2h) to mix the two evenly, and then continue to pour 50mL into the beaker Solution B, continue to stir magnetically at 70°C (300rpm, 2h);

[0055] (4) Leave the mixed solution in (3) for 2 hours, then suck out the upper layer of kerosene with a dropper, leaving the layer solution for subsequent use;

[0056] (5) adjust the...

Embodiment 2

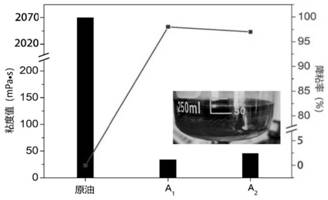

[0058] Taking crude oil from a certain block of Shengli Oilfield in China as the research object, the viscosity-reducing performance of the amphiphilic nano-viscosity reducer was tested. The specific crude oil information is shown in Table 1.

[0059] Table 1 Basic information of crude oil used for testing

[0060]

[0061] Crude oil viscosity reduction test steps:

[0062] (1) Pour the 10g amphiphilic graphene oxide thick oil viscosity reducer solution (the concentration of the amphiphilic graphene oxide heavy oil viscosity reducer is 10mg / mL) prepared in embodiment 1 into a 150mL beaker, and then pour 90g Mineralized water of the target oil reservoir, magnetic stirring (300rpm) for 10 minutes to mix the two evenly;

[0063] (2) Take a cleaned 250mL beaker, pour 15g of the solution in (1) into it, and then slowly pour 35g of crude oil into it;

[0064] (3) Slowly mechanically stir the oil-water mixture in (2) at a speed of 6 rpm at the target reservoir temperature of 46°...

Embodiment 3

[0070] Taking crude oil from a certain block of Henan Oilfield in China as the research object, the viscosity-reducing performance of the amphiphilic nano-viscosity reducer was tested. The specific crude oil information is shown in Table 2.

[0071] Table 2 Basic information of crude oil for testing

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com