Ultrathin headrest for automobile seat

A technology for car seats and headrests, applied in vehicle seats, vehicle parts, special positions of vehicles, etc., can solve the problems of difficult adjustment of front and rear positions, thinning of thickness, etc., to ensure stability and firm positioning , the effect of broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

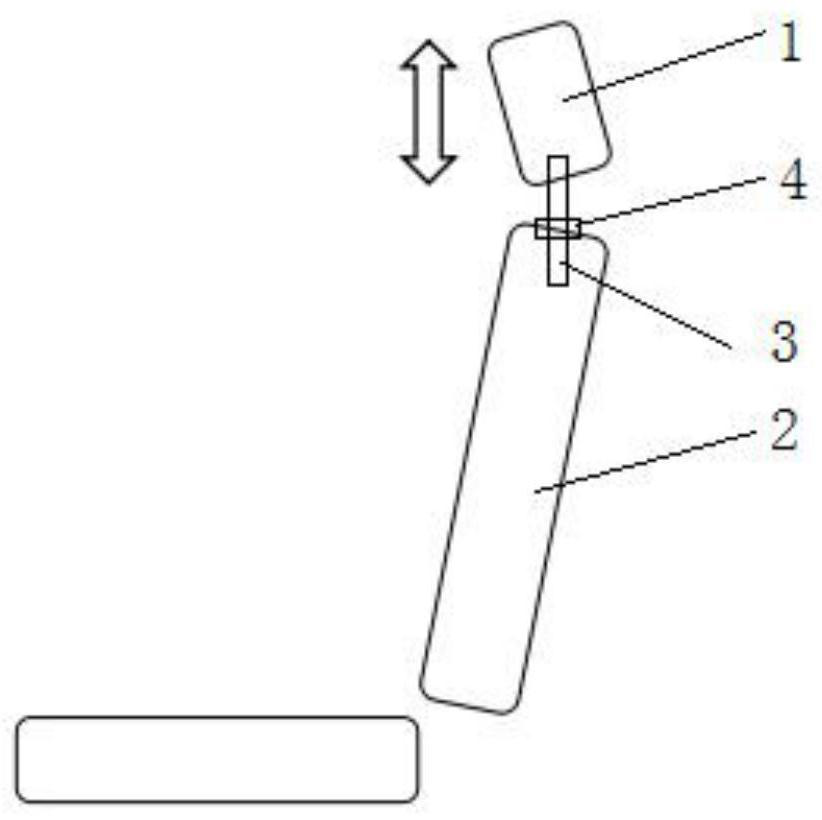

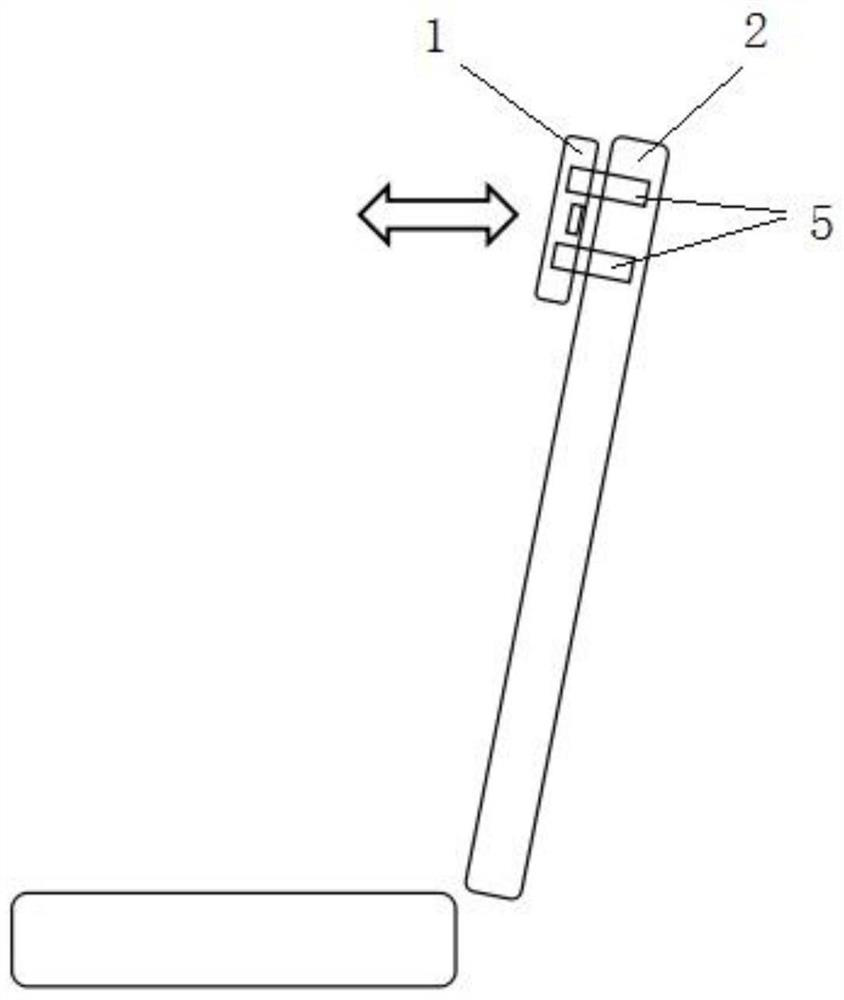

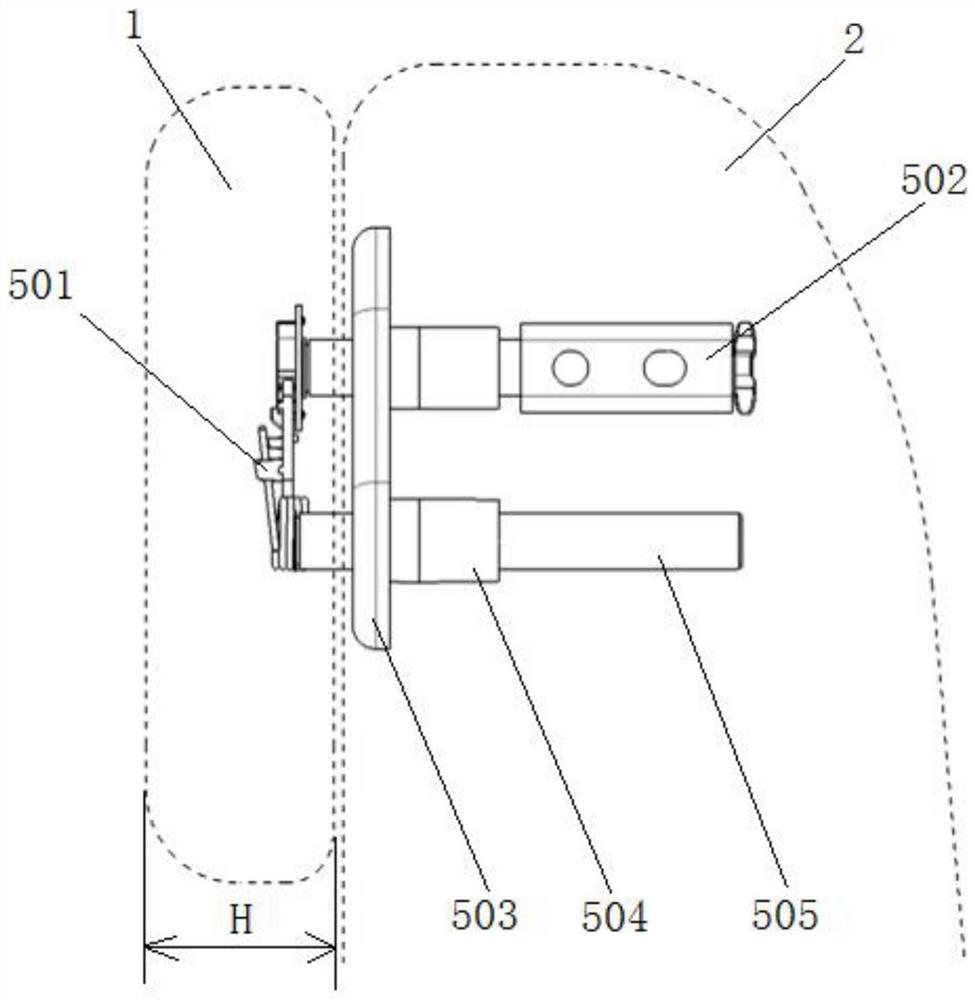

[0036] Such as Figure 2-8 As shown, an ultra-thin headrest for a car seat includes a headrest body 1 and a seat back 2, and the headrest body 1 is provided with a group of connecting accessories 5 on the top of the seat back 2. The pillow body 1 is away from or close to the seat back 2 through the adjustable structure of the connecting accessory 5 . Specifically, the thickness of the headrest body 1 is set to H, and the H≤40mm.

[0037] In one embodiment, the seat back 2 is configured as an ultra-thin structure, and the headrest body 1 is connected to the top front side of the seat back 2 through the connecting attachment 5 .

[0038] In another embodiment, the seat back 2 adopts an existing thick structure, a U-shaped groove is reserved on the top of the seat back 2, and the headrest body 1 is connected to the seat through the connecting attachment 5. Describe the U-shaped groove.

[0039] Such as Figure 3-8 As shown, the connecting accessories include an unlocking mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com