Combined three-dimensional planting system

A three-dimensional planting and box technology, which is applied in liquid fertilizer adjustment system, liquid fertilizer distribution, agricultural gas emission reduction, etc., can solve the problems of large land consumption, light energy, water source, heat, poor adjustment flexibility, complex planting structure, etc. , to achieve the effect of excellent crop growth environment, low cost and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

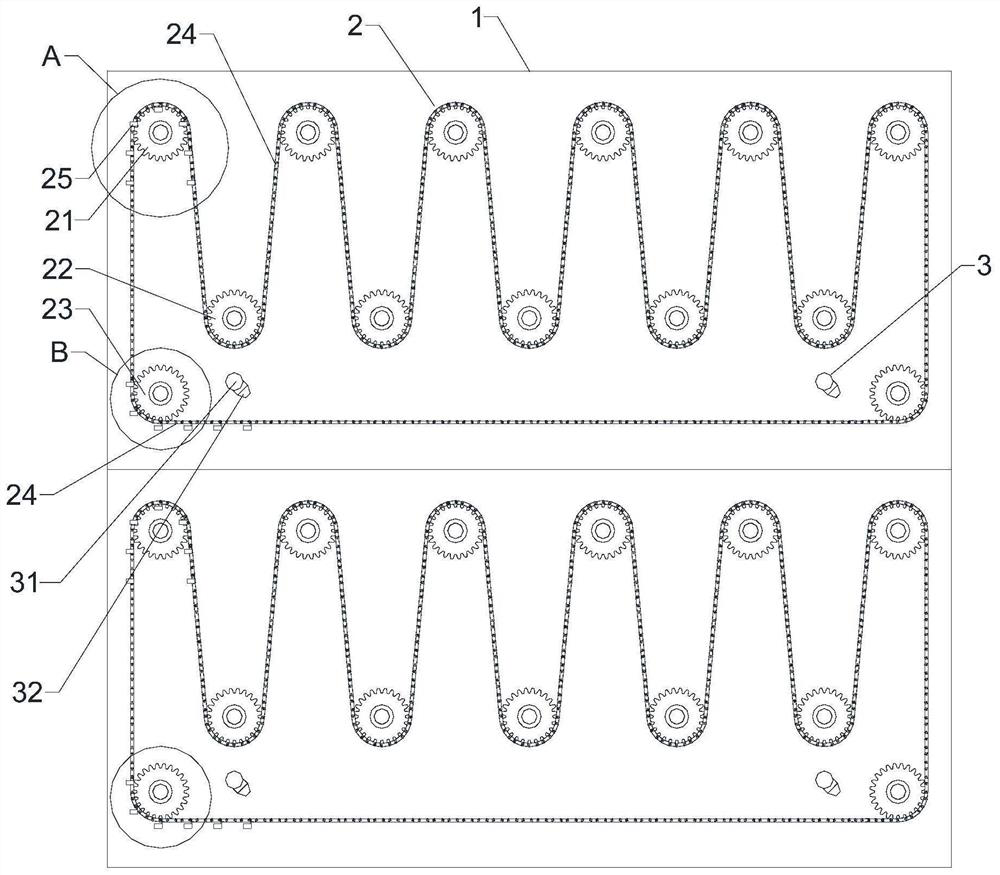

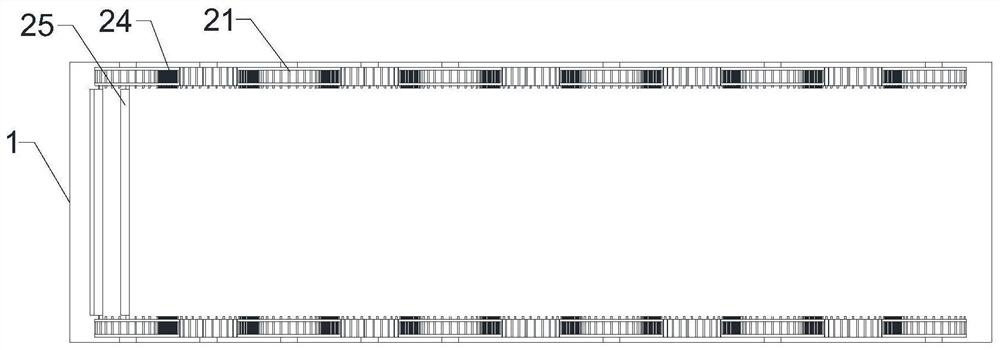

[0043] A combined three-dimensional planting system includes several planting unit boxes stacked up and down. The planting unit box includes an accommodating box body 1 , a circulating traveling mechanism 2 and a spray assembly 3 . The circulation traveling mechanism 2 comprises some upper gears 21, some middle gears 22, two lower gears 23, transmission chain 24, planting frame 25 and gear drive. The upper gear 21 , the middle gear 22 and the lower gear 23 are mounted symmetrically on both side walls of the housing box 1 from top to bottom. The middle gear 22 is arranged below the midpoint of the line connecting the adjacent upper gears 21 , and the two lower gears 23 are respectively arranged below the upper gears 21 located at both ends.

[0044] The upper chain section of the transmission chain 24 is alternately wound around the outer circumference of the upper gear 21 and the middle gear 22 , and the lower chain section of the transmission chain 24 is wound around the out...

Embodiment 2

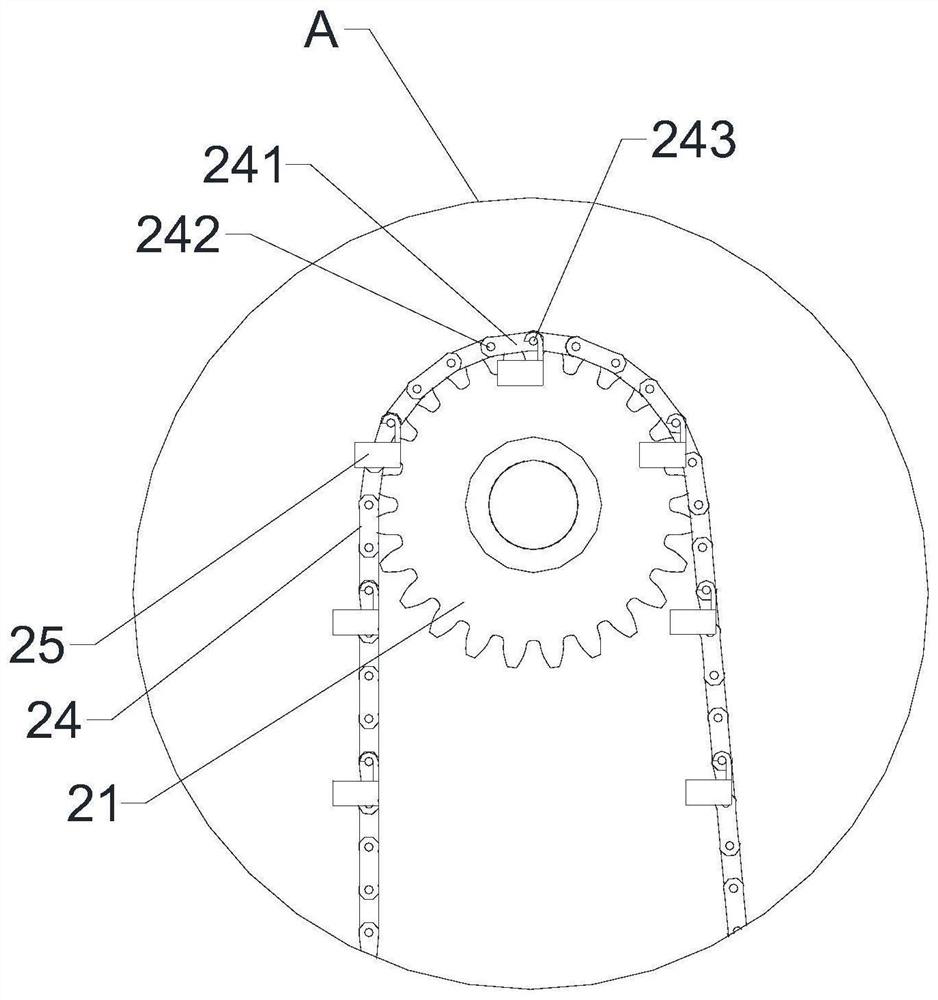

[0048] The difference between this embodiment and Embodiment 1 is that: the transmission chain 24 includes a chain plate 241 , a sleeve, a connecting pin 242 and an extension pin 243 . The planting frame 25 includes hooks 251 and transverse frames 252 arranged symmetrically. The transmission chains 24 installed symmetrically on the two side walls of the housing box 1 run synchronously, and the hooks 251 at both ends of the transverse frame 252 are respectively hung on the extension pins 243 at the symmetrical walking positions on the two side walls of the housing box 1 .

Embodiment 3

[0050] The difference between this embodiment and Embodiment 2 is that the planting frame 25 also includes a hollow bottom sheet 253, which is convenient for supporting the crops in the horizontal frame 252, and can leak excess water to avoid water accumulation in the horizontal frame 252.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com