Integrated battery module

A technology of battery modules and integrated modules, which is applied to battery components, circuits, electrical components, etc., and can solve the problems of poor welding of battery poles and conductive sheets, and easy failure of welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

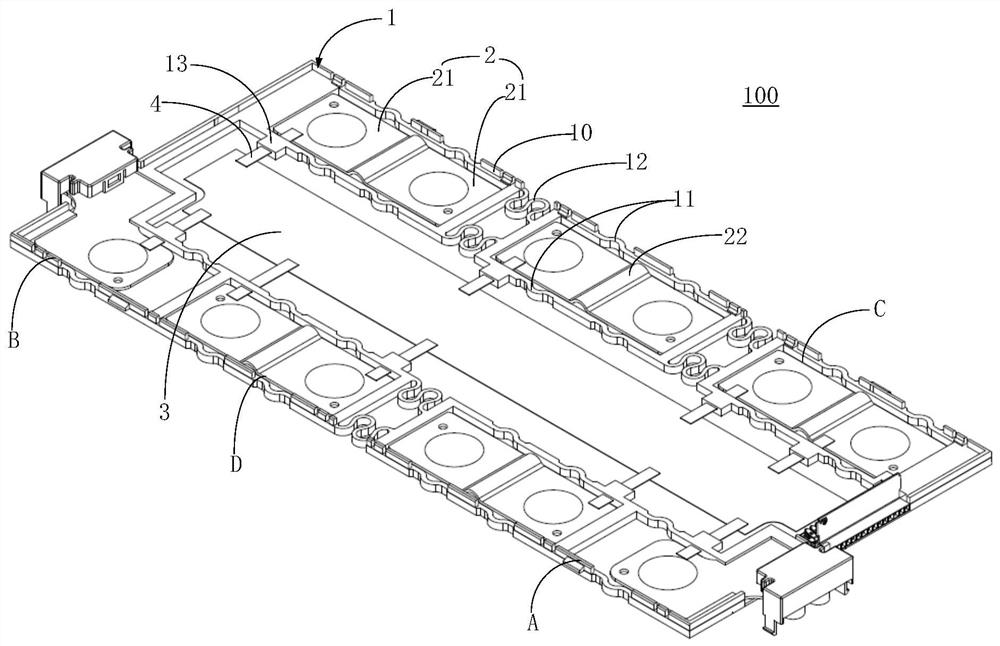

[0033] Embodiment 1 of the present invention provides an integrated wiring harness isolation board integrated module 100 on the one hand, such as figure 1 shown.

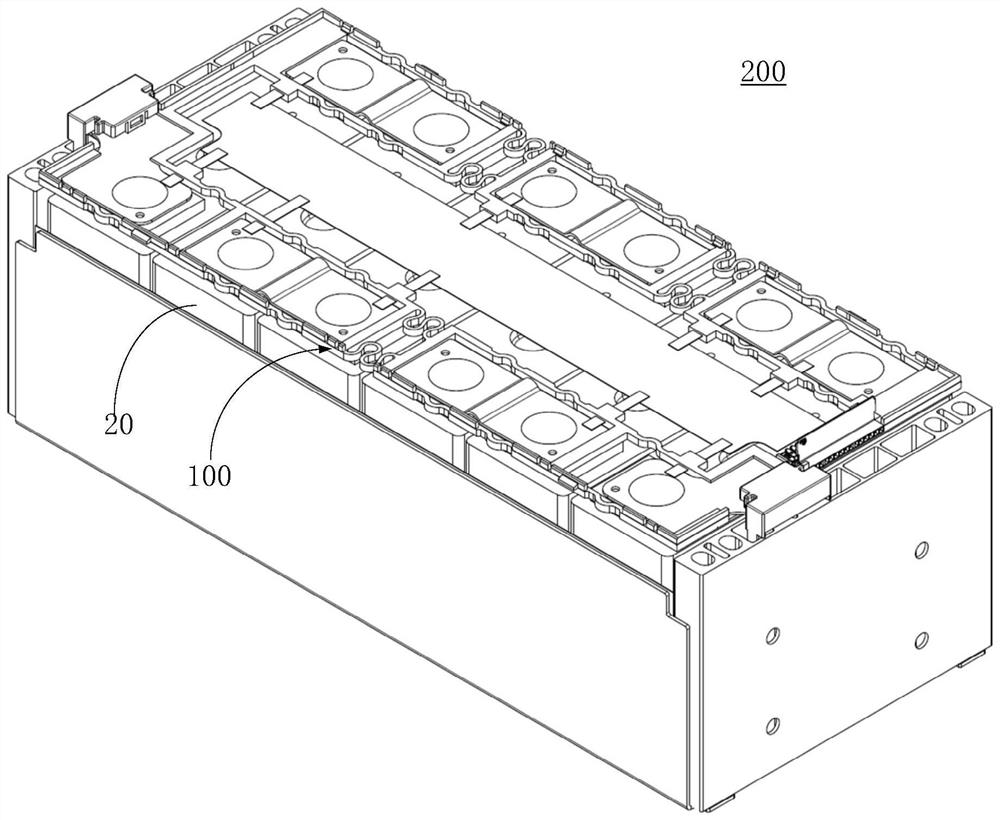

[0034] On the other hand, Embodiment 1 of the present invention also provides a battery module 200 using the integrated wire harness isolation board integrated module 100, such as figure 2 As shown, the wiring harness isolation board integrated module 100 is horizontally arranged above the battery cells 20 of the battery module 200 as a whole.

[0035] Such as figure 1 and 2 As shown, the wiring harness isolation board integrated module 100 includes several conductive sheet groups 2 and isolation boards 1 .

[0036] Each conductive sheet group 2 includes at least one conductive sheet 21, and each conductive sheet 21 is arranged on a pole of a corresponding electric core 20 (not specifically shown in the figure); When using two conductive sheets 21, two adjacent conductive sheets 21 are connected end-to-end alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com