External rotor axial magnetic flux hub motor vibration and noise analytical calculation method

A technology of axial magnetic flux and hub motors, applied in design optimization/simulation, special data processing applications, etc., can solve problems such as poor accuracy and failure to consider sound radiation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

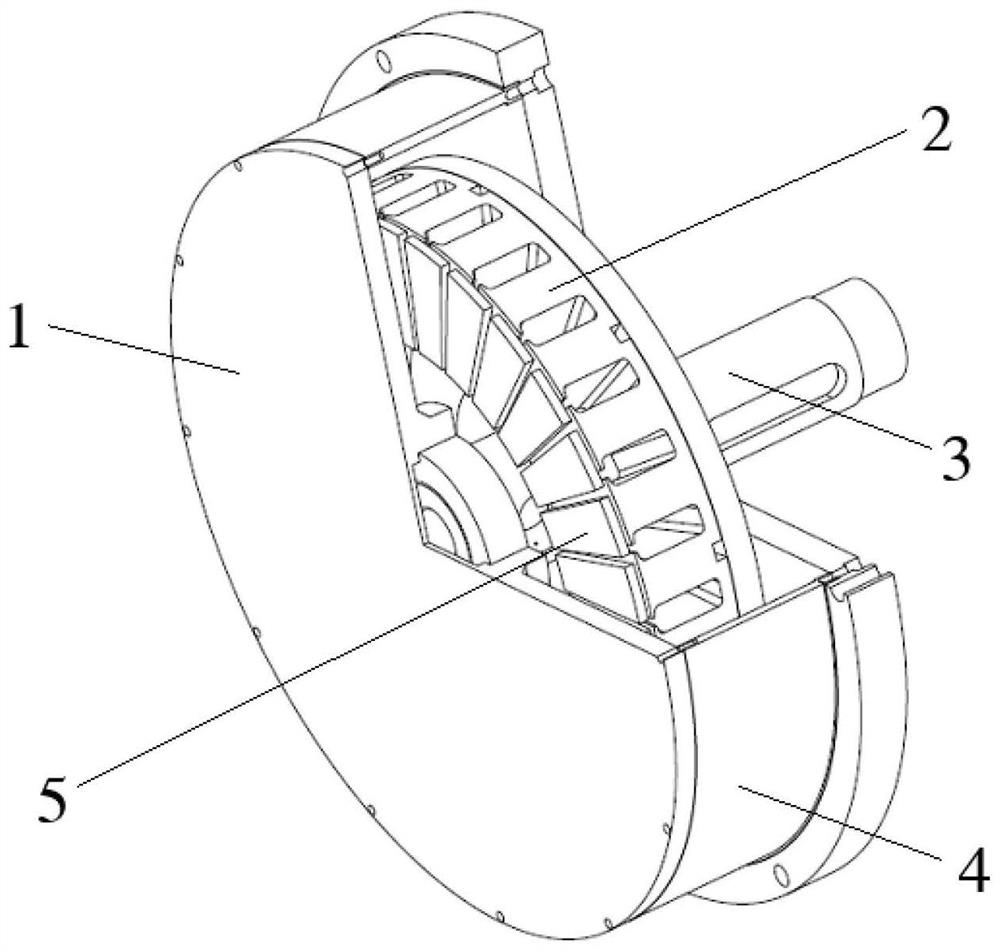

[0080] For a certain type of 30-pole 27-slot (30p27s) external rotor axial flux hub motor with a rated speed of 600rpm, its structure is as follows figure 1 Shown, carried out implementation test of the present invention;

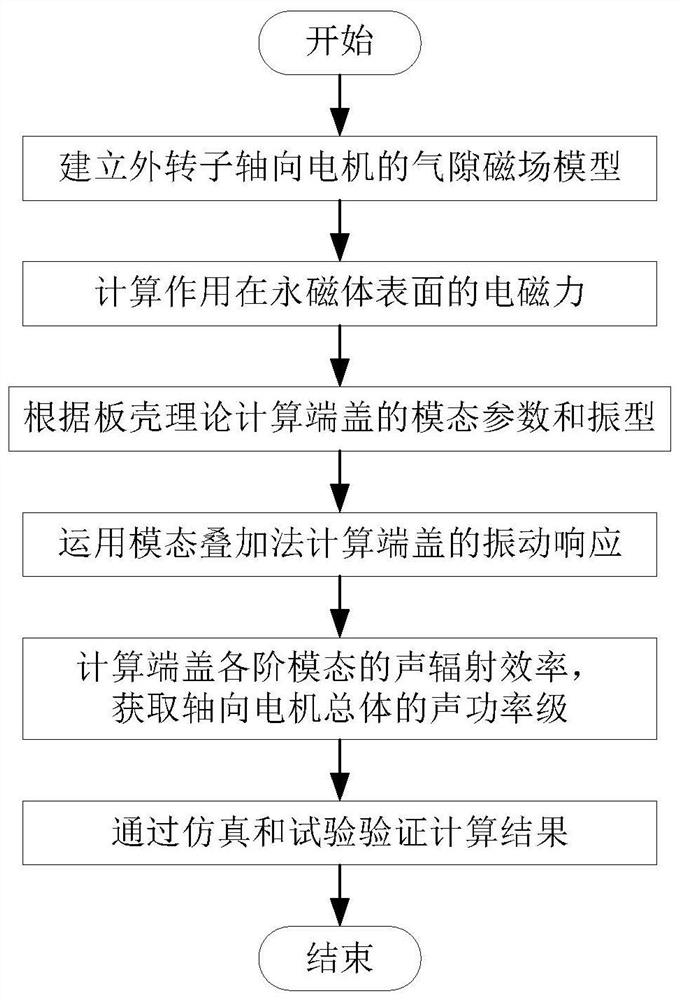

[0081] Such as figure 2 As shown, this embodiment provides a technical solution: a vibration and noise analytical calculation method for an axial flux hub motor with an outer rotor, including the following steps:

[0082] Step 1): Build the outer rotor axial flux motor (ie figure 2 The air gap magnetic field model of the axial motor in ) considers the influence of the edge effect through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com