Special-shaped lamp box ceiling structure for high-speed ship, and mounting method therefore

A ceiling structure and special-shaped technology, which is applied to lighting devices, lighting auxiliary devices, components of lighting devices, etc., can solve the problems of difficult to form diverse structures, single lighting effect, low recognition and aesthetics, etc. Recognition and aesthetics, improve the effect of light and shadow, and improve the recognition of boats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

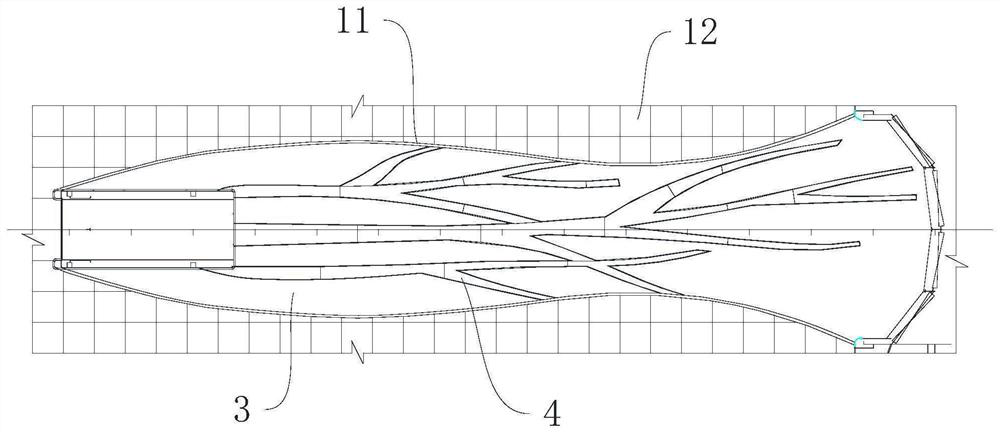

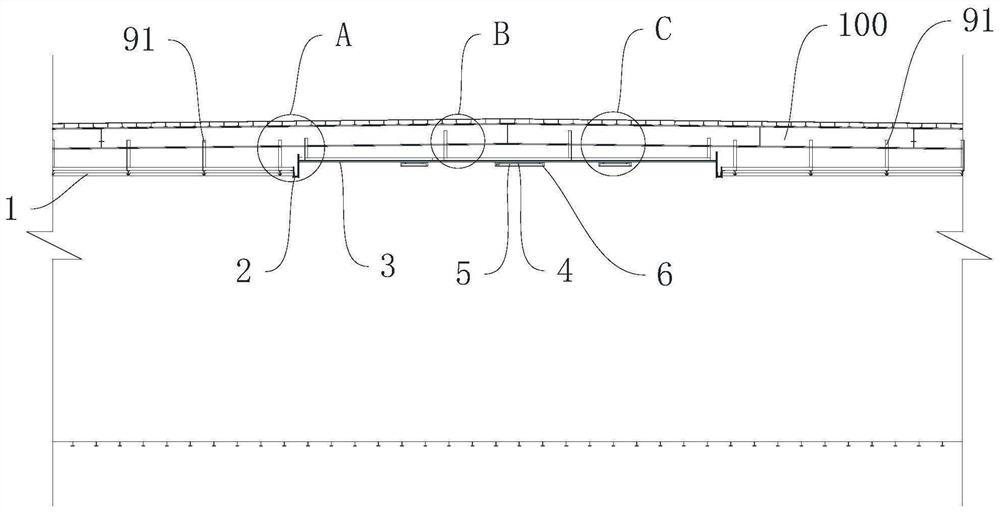

[0055] Refer below Figure 1-Figure 5 The special-shaped light box ceiling structure for high-speed ships according to a specific embodiment of the present invention is described.

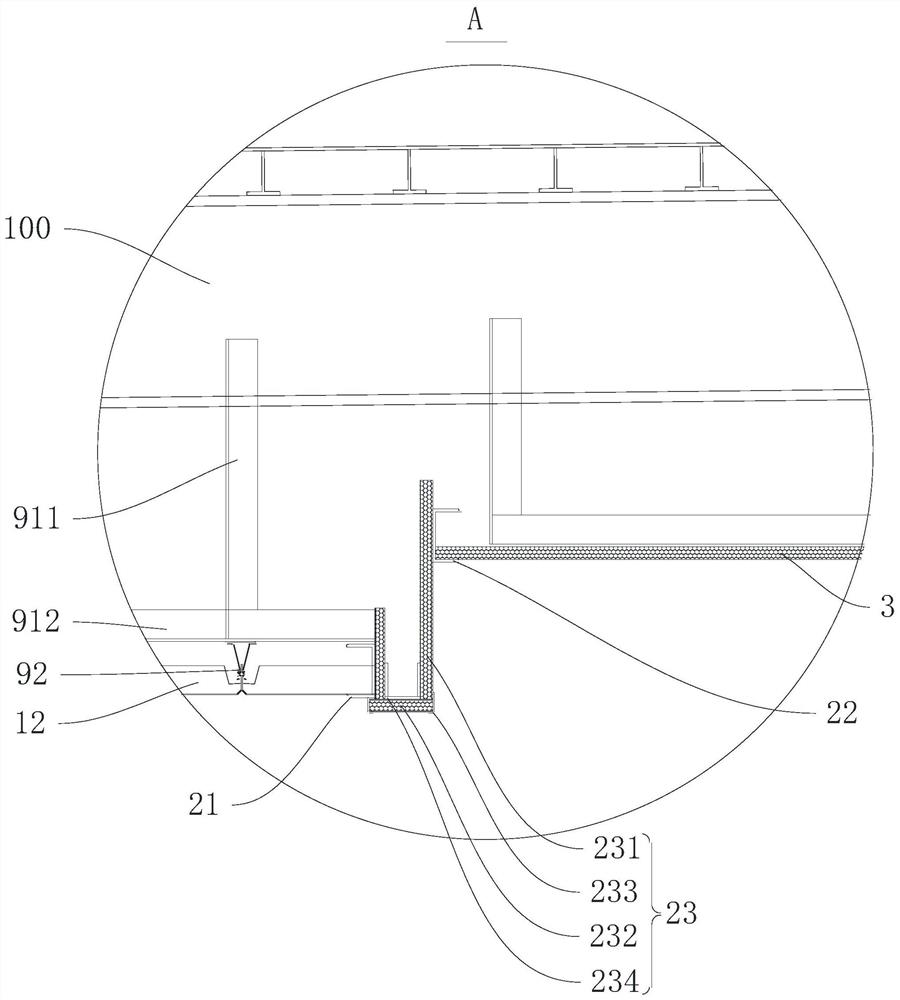

[0056] The special-shaped light box ceiling structure for high-speed ships in this embodiment includes an aluminum buckle structure 1, an edge structure 2, an aluminum honeycomb panel 3, a special-shaped mounting plate 4, a lamp 5, a special-shaped closing plate 6, a connecting component 7, and a plurality of hanging components 91.

[0057] The aluminum buckle structure 1 is suspended on the structural beam 100 , and the aluminum buckle structure 1 is provided with a special-shaped installation opening 11 . The aluminum buckle structure 1 includes a plurality of aluminum buckle plates 12 connected in sequence.

[0058] The outer peripheral wall of the edge-receiving structure 2 is connected with the inner wall of the special-shaped installation opening 11 . The edge trimming structure 2 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com