Coal mine large-range dust monitoring system and method

A monitoring system and a wide range of technology, applied in mining equipment, mining equipment, earth-moving drilling, etc., can solve the problems of excessive dust concentration, small dust range, reducing dust concentration, etc., to achieve high safety and improve productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

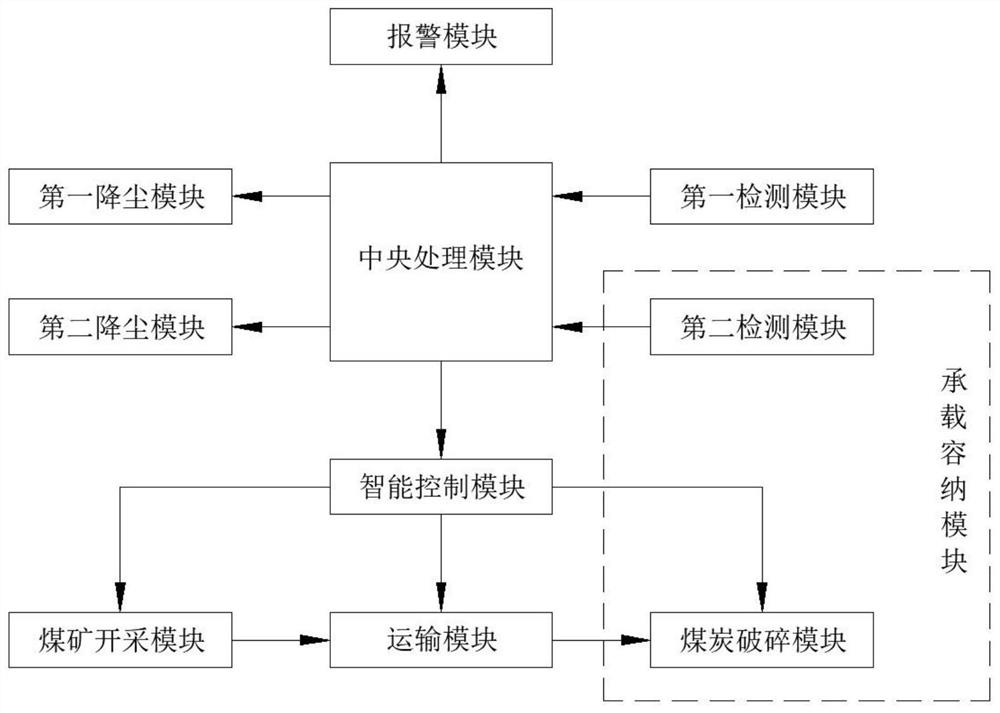

[0065] refer to Figure 1-5 , a large-scale dust monitoring system for coal mines, including:

[0066] coal mining module;

[0067] The first detection module;

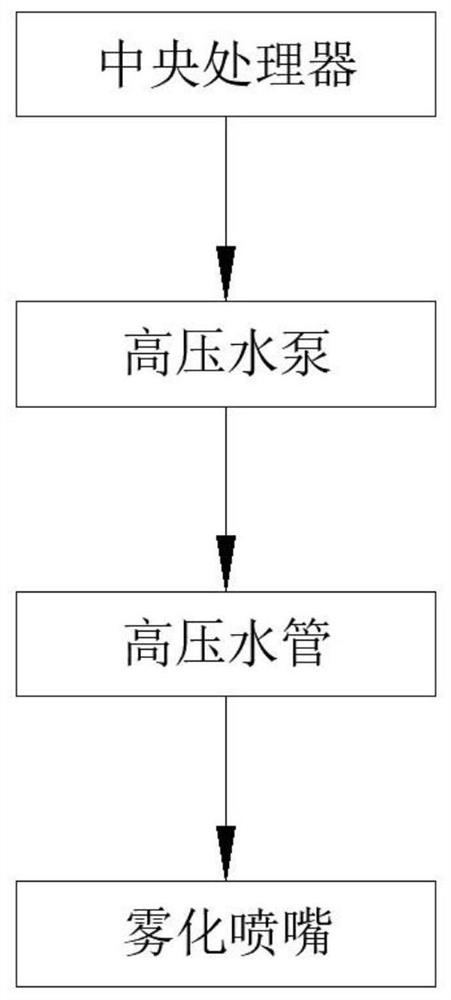

[0068] The first dust suppression module;

[0069] transport module;

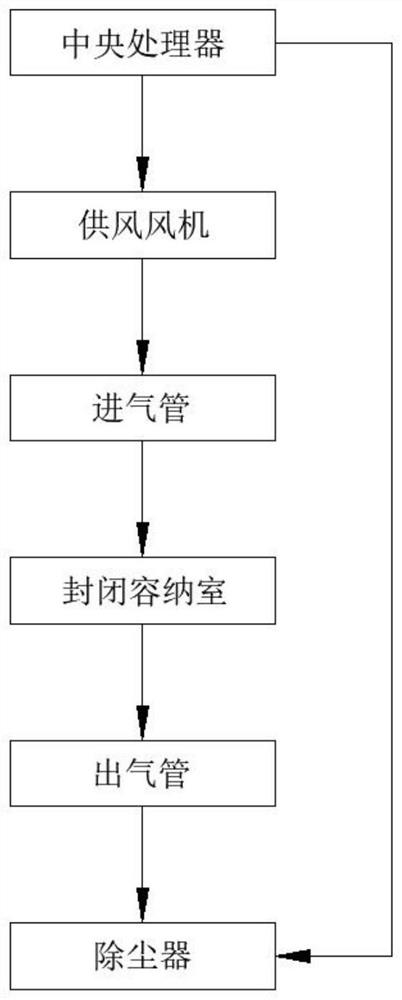

[0070]Carrying the accommodation module;

[0071] Coal crushing module;

[0072] The second detection module;

[0073] The second dust suppression module;

[0074] central processing module;

[0075] Intelligent control module;

[0076] Alarm module;

[0077] in:

[0078] The coal mining module includes:

[0079] Coal mining machine used for mining coal mines (coal mining machine is one of the main equipment of fully mechanize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com