Circulating clarification equipment

A kind of equipment and cone technology, which is applied in the field of circulating clarification equipment, can solve the problems of low treatment efficiency, structural differences, and difficult dredging, and achieve the effects of low energy consumption, high water production capacity, and large cross-sectional area of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

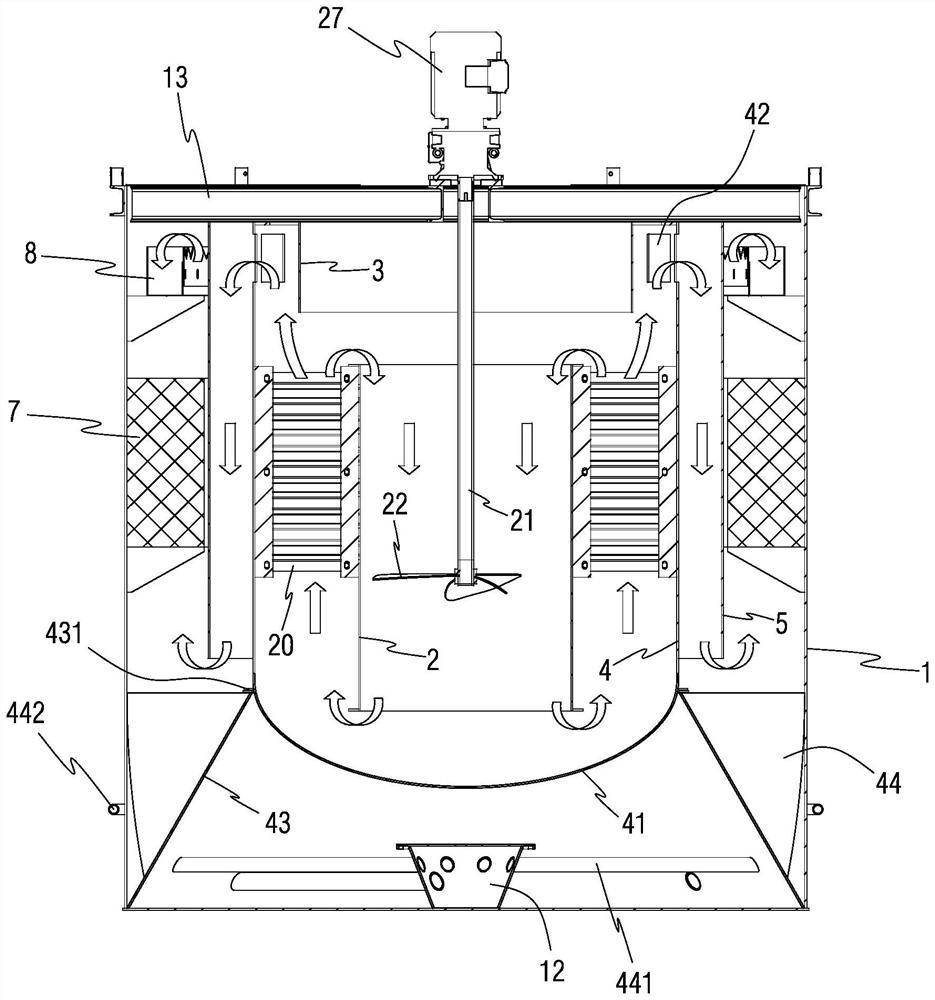

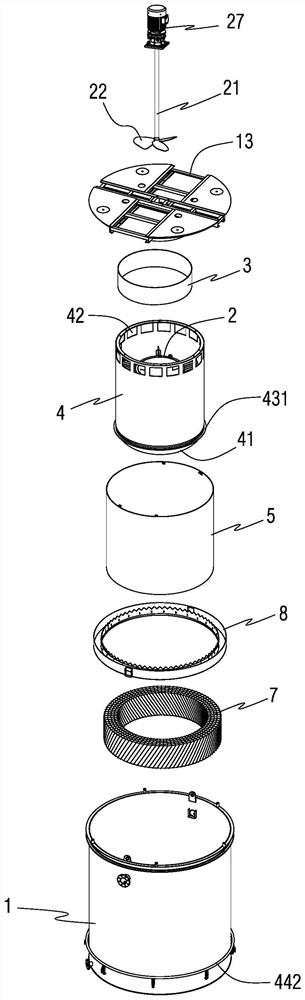

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present application, specific implementation methods of the present application will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

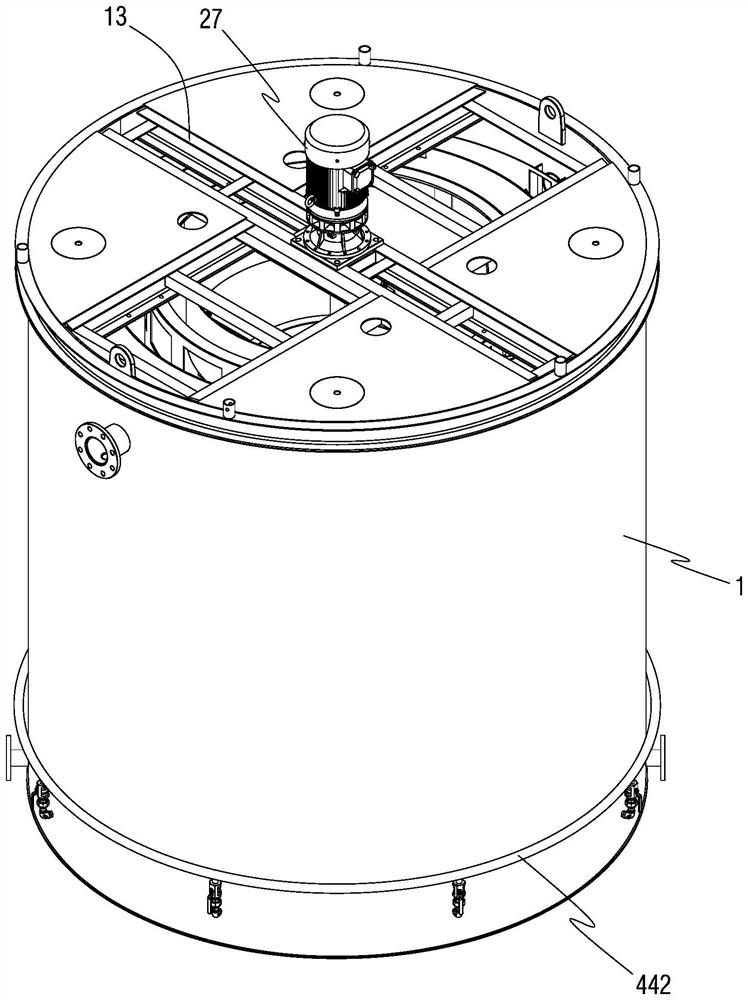

[0026] Such as Figure 1-3 As shown, the present application proposes a circular clarification device, which includes a cylindrical clarification tank 1 , and the entire water treatment process is carried out inside the clarification tank 1 . The floor area of the entire equipment of the present application is determined by the diameter and height of the clarifier 1, so it is easy to set a reasonable size range according to the constraints of road transportation, which is convenient for saving transportation costs and improving the competitiveness of products.

[0027] When the diameter and height of the clarification tank 1 are limited, it is necessary to consider inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com