Nested box type floating disc structure

A nested, floating disc technology, applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of safety accidents, structural asymmetry, uneven force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

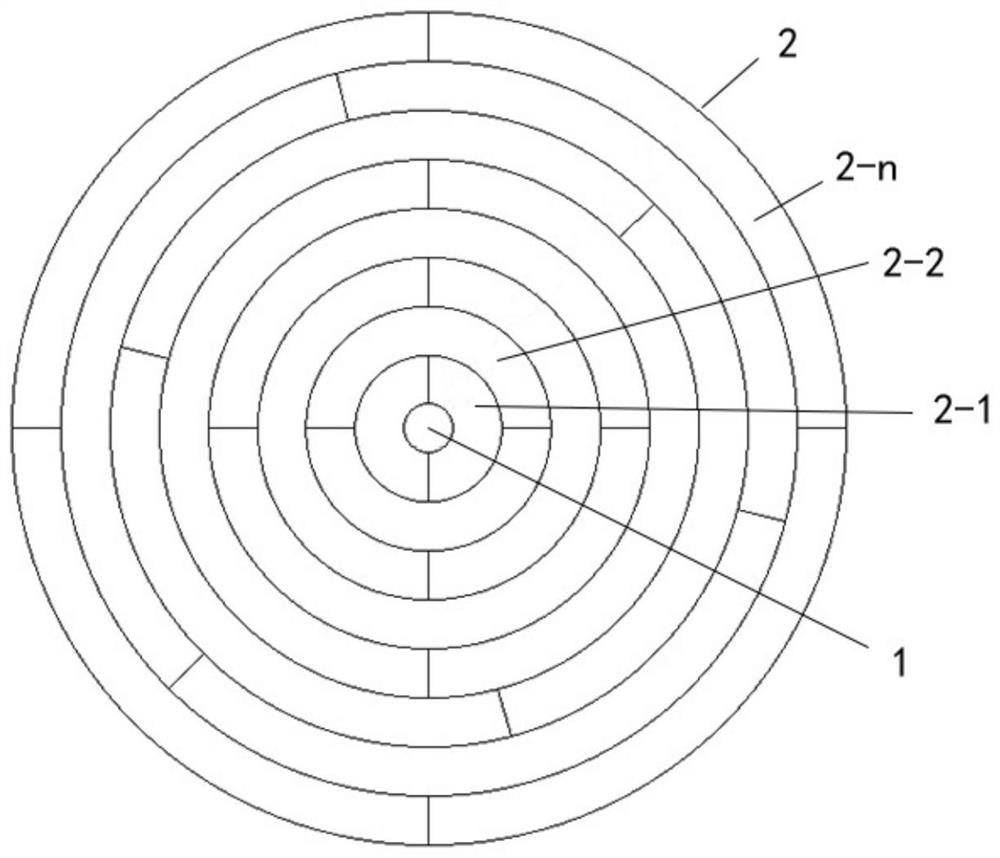

[0023] figure 1 It is a nested box-type floating disc structure shown in a feasible embodiment of the present application. The floating disc structure includes: a nested intermediate body 1 and a nested assembly 2 surrounding the outer periphery of the nested intermediate body 1; The nesting intermediate body 1 and the nesting assembly 2 are connected by inner and outer ring buckles 3 .

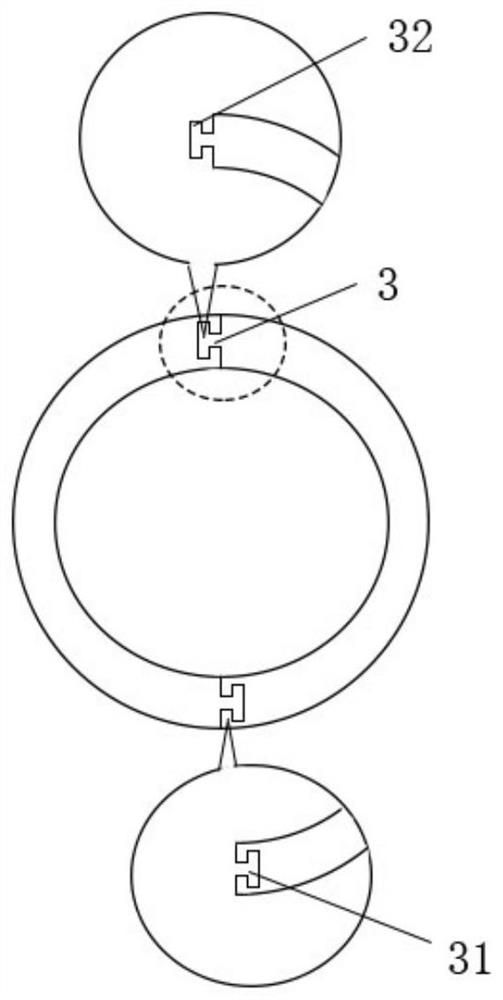

[0024] figure 2 A schematic cross-sectional view of an inner and outer ring buckle 3 is shown, figure 2 The inner and outer ring buckles 3 include an inner ring buckle 31 and an outer ring buckle 32, and the inner ring buckle 31 and the outer ring buckle 32 are both arranged on the side wall of the buoyancy unit.

[0025] In a feasible implementation, the inner ring buckle 31 is a buckle that is recessed inward along the side wall of the buoyancy unit to form a T-shaped groove, and the outer ring buckle 32 is convex outward along the side wall of the buoyancy unit. Pull up to form a T-sh...

Embodiment 2

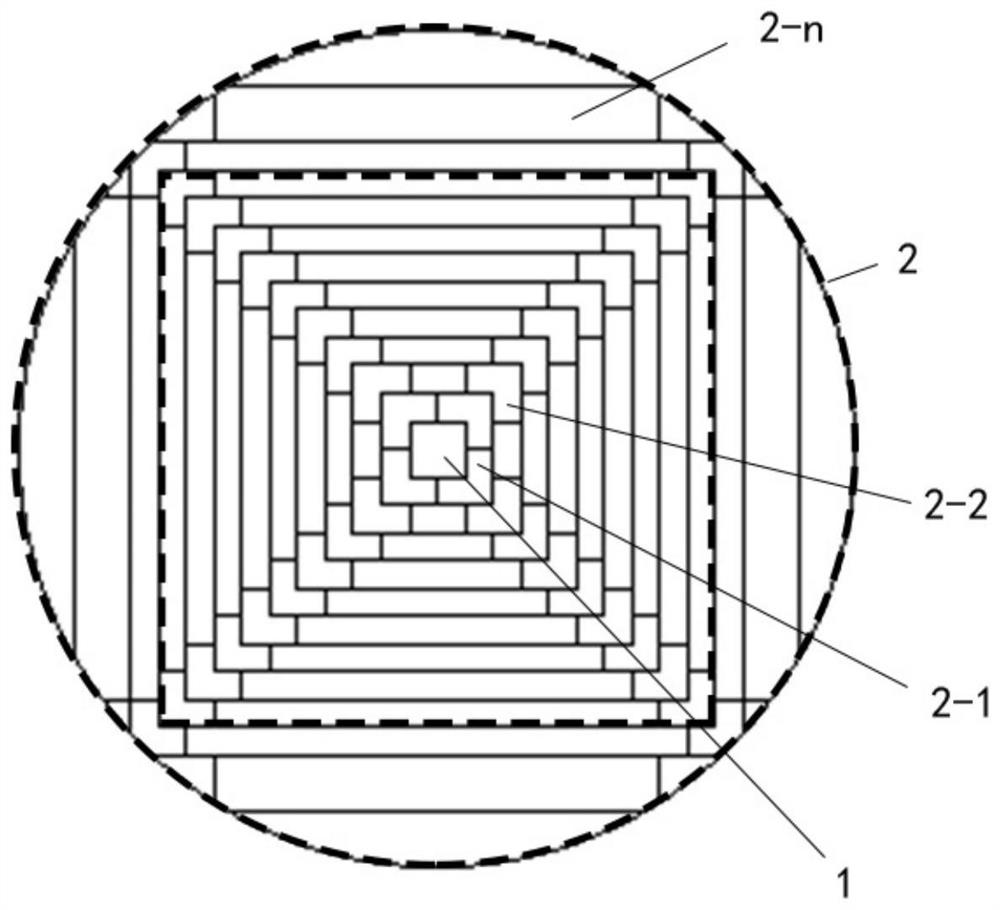

[0041] image 3 It is a nested box-type floating disc structure shown in a feasible embodiment of the present application. The floating disc structure includes: a nested intermediate body 1 and a nested assembly 2 surrounding the outer periphery of the nested intermediate body 1; The nesting intermediate body 1 and the nesting assembly 2 are connected by inner and outer ring buckles 3 .

[0042] In a feasible implementation, the inner ring buckle 31 is a buckle that is recessed inward along the side wall of the buoyancy unit to form a T-shaped groove, and the outer ring buckle 32 is convex outward along the side wall of the buoyancy unit. Pull up to form a T-shaped raised buckle.

[0043] It should be noted that, in actual production, it is necessary to install connecting fixing bolts or bayonet sockets on the upper and lower sides of the adjacent annular assemblies to increase the stability of the overall structure.

[0044] In a feasible implementation manner, multiple inn...

Embodiment 3

[0059] Figure 4 It is a nested box-type floating disc structure shown in a feasible embodiment of the present application. The floating disc structure includes: a nested intermediate body 1 and a nested assembly 2 surrounding the outer periphery of the nested intermediate body 1; The nesting intermediate body 1 and the nesting assembly 2 are connected by inner and outer ring buckles 3 .

[0060] In a feasible implementation, the inner ring buckle 31 is a buckle that is recessed inward along the side wall of the buoyancy unit to form a T-shaped groove, and the outer ring buckle 32 is convex outward along the side wall of the buoyancy unit. Pull up to form a T-shaped raised buckle.

[0061] In a feasible implementation manner, multiple inner and outer ring buckles 3 are provided on the side wall of the buoyancy unit.

[0062] It should be noted that the present application is not limited to the use of this inner and outer ring buckle, and inner and outer ring buckles in other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com