Anti-explosion intelligent inspection robot

An intelligent inspection and robot technology, applied in the field of robots, can solve the problems of no self-storage function, shooting, data loss, etc., and achieve the effect of improving explosion-proof capability and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

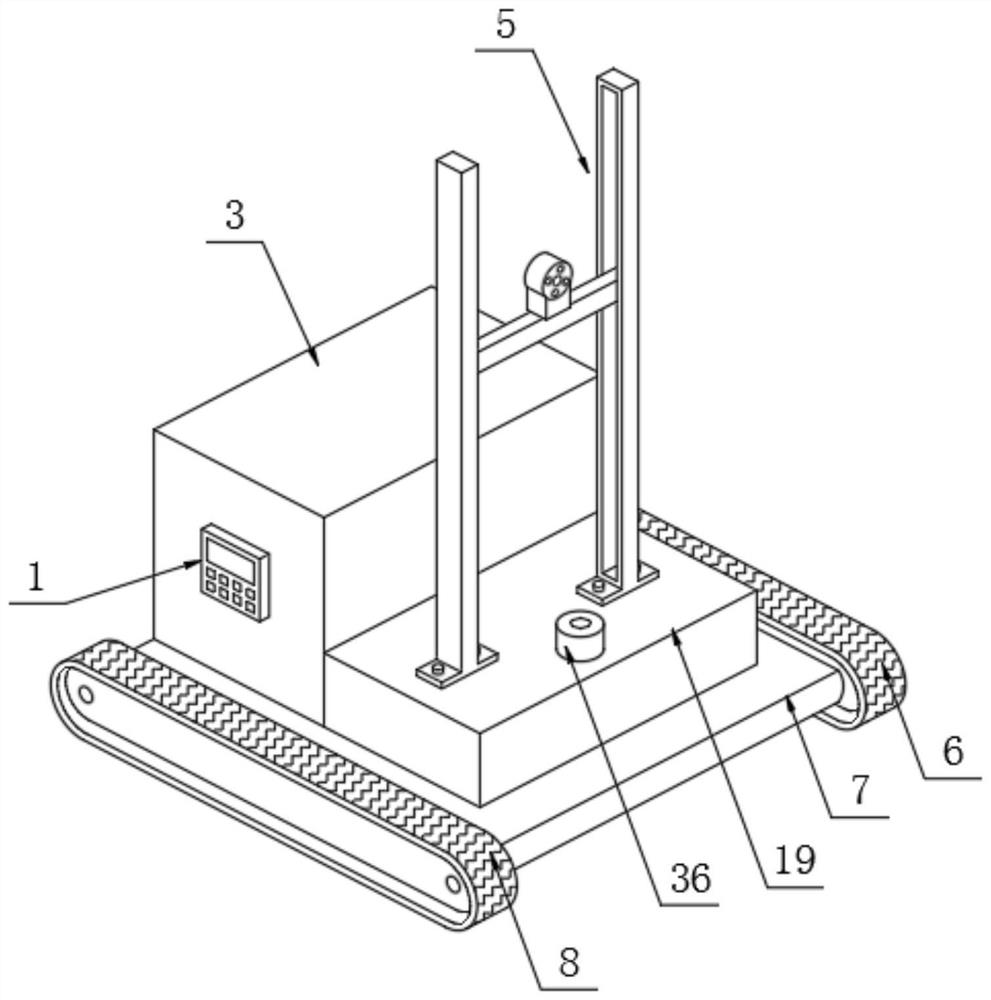

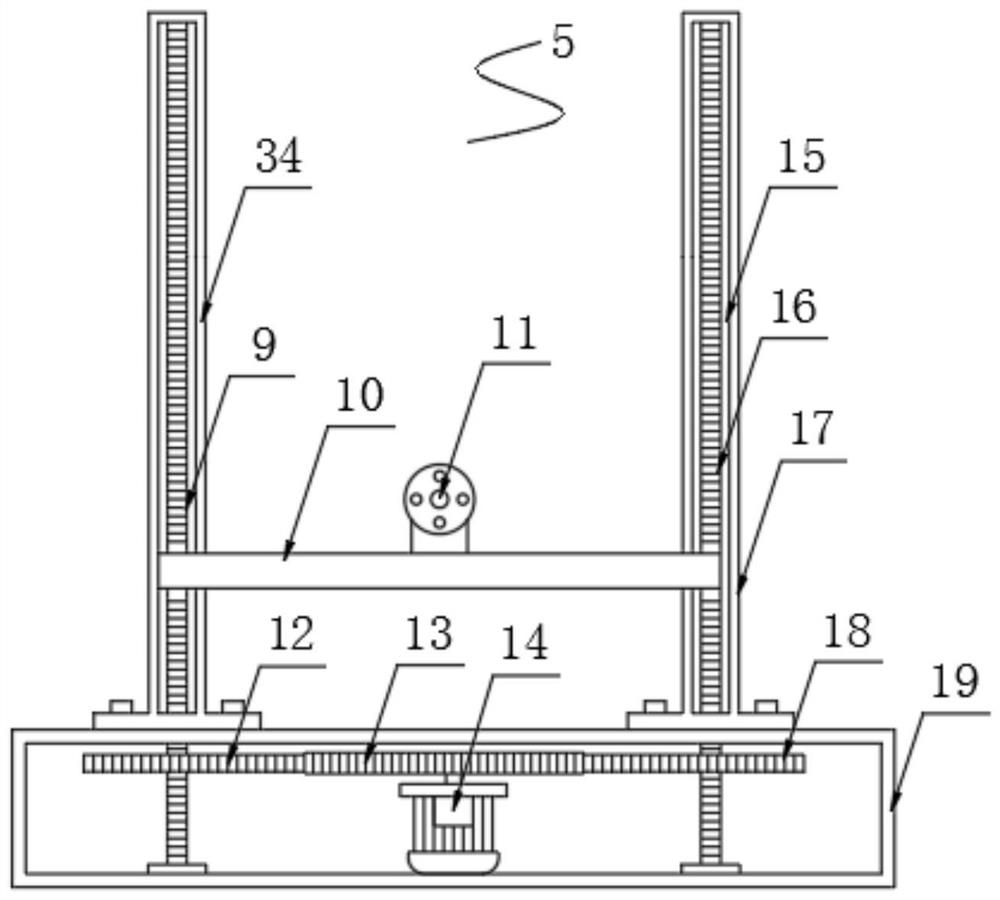

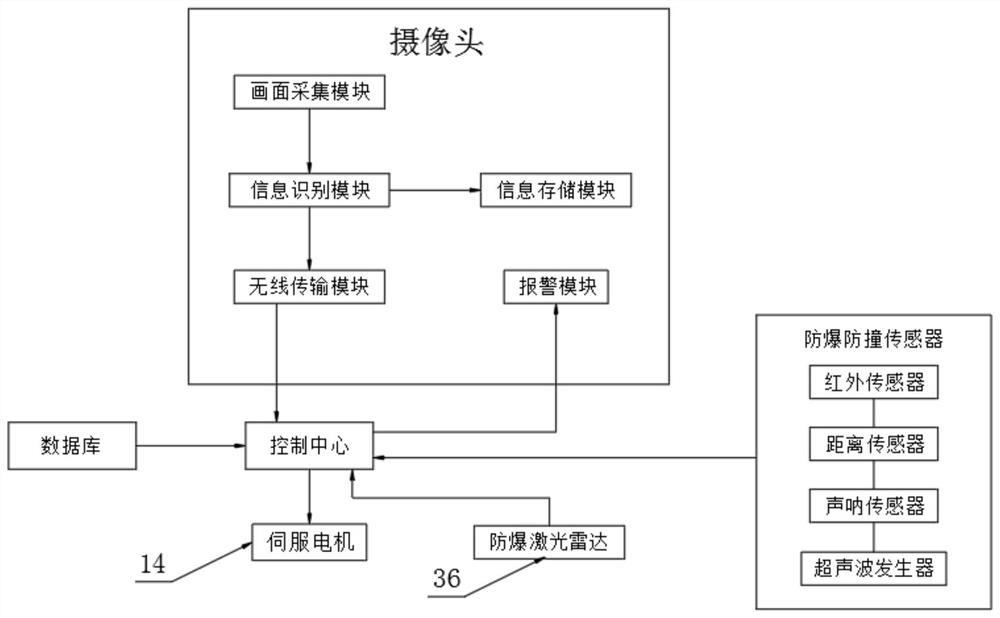

[0022] see Figure 1~3 , in an embodiment of the present invention, an explosion-proof intelligent inspection robot includes a body 7 and a first crawler 6 and a second crawler 8 installed on both sides of the body 7. A sensor box 3 is fixedly connected to the upper surface of the body 7. A control center is installed inside the sensing box, and a display controller 1 is fixedly connected to the outside of the sensing box 3, and the display controller 1 is connected with the control center in the sensing box. The model of the display controller 1 is DKC-Y110. The upper surface of the body 7 is located at the front side of the sensor box 3 and an adjustment mechanism 5 is installed. The adjustment mechanism 5 includes a first screw rod 9, a mounting rod 10, a camera 11, a first small Gear 12, bull gear 13, explosion-proof servo motor 14, limit groove 15, the second screw mandrel 16, the second support 17, the second pinion 18, storage box 19 and first support 34, the upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com