Dust fall type peanut picking harvester

A technology for harvesting machines and peanuts, which is applied to digging harvesters, harvesters, excavators, etc., can solve the problems of short duration of spray dust removal, high mechanical power, waste of water resources, etc., and achieve high quality peanut harvesting, Improve service life and smooth working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

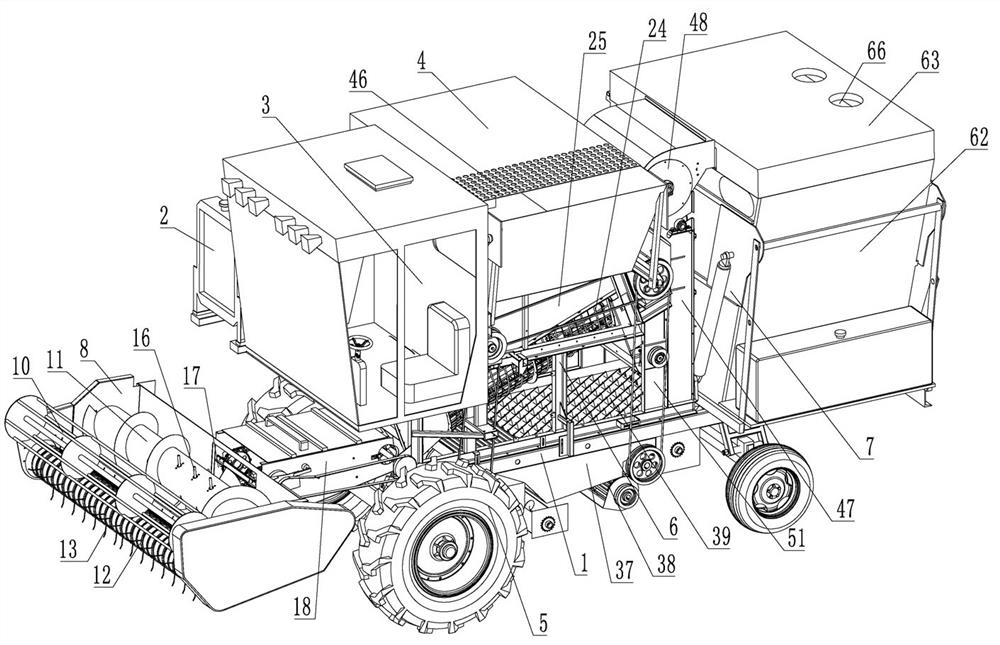

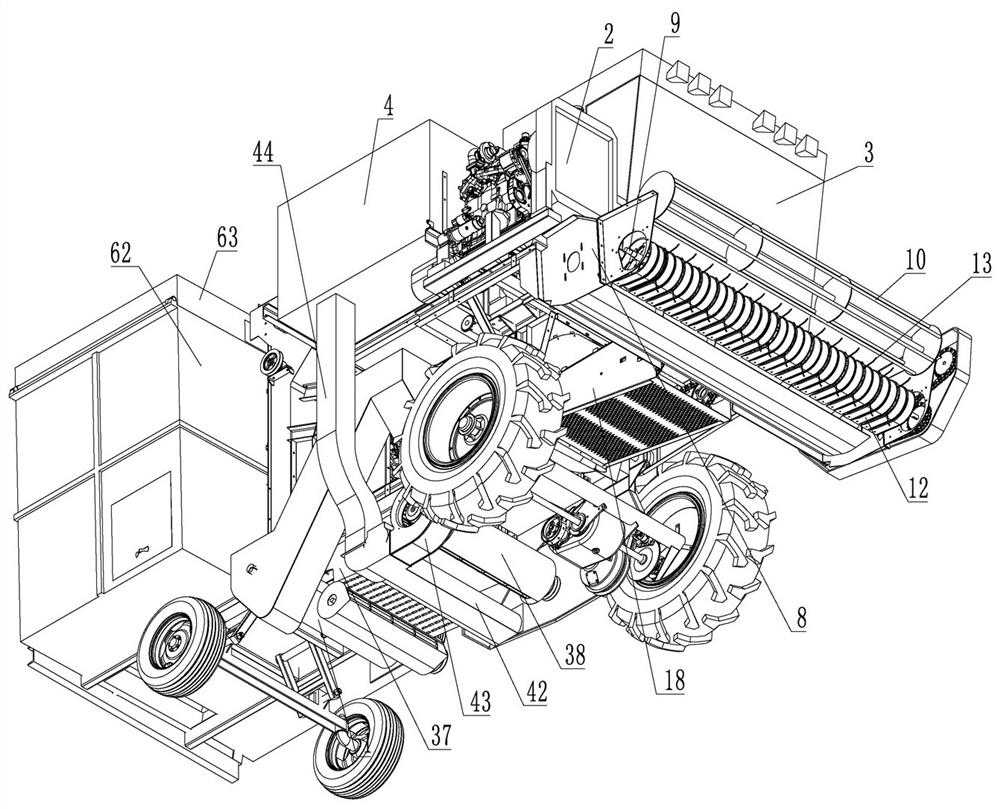

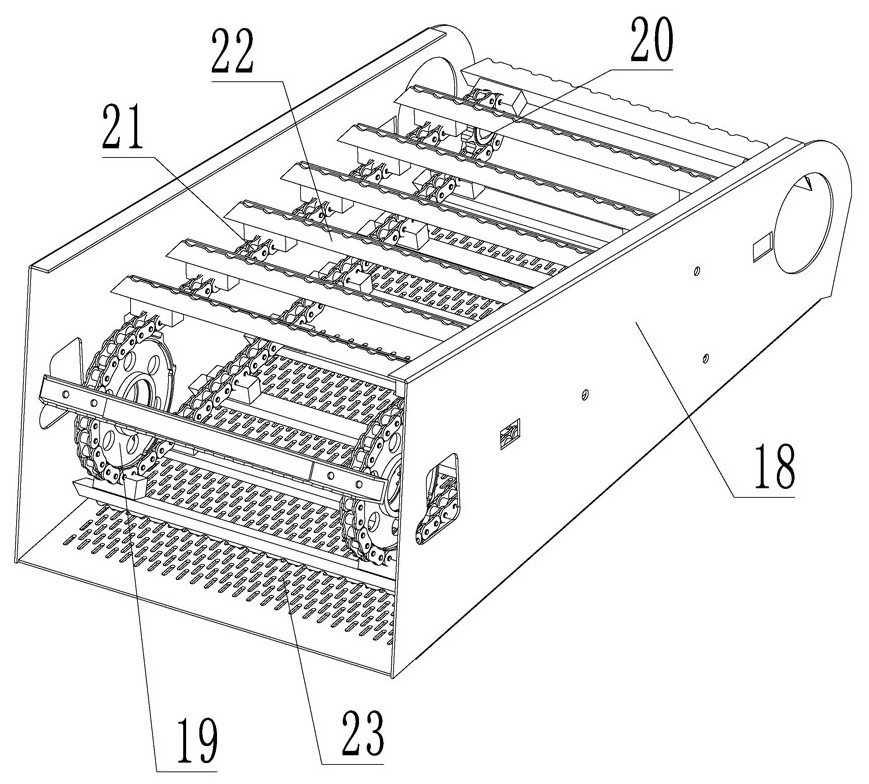

[0038] Such as Figure 1-18As shown, the dust-reducing peanut picking and harvesting machine includes chassis 1, engine 2, cab 3, peanut picking and picking platform system, peanut inclined conveying system, peanut fruit removing system, screening system, fruit collecting system, and peanut seedling crushing and conveying system , fruit box 4 and dust-reducing grass collection box, the left and right sides of chassis 1 are rotated and provided with traveling wheels 5, and frame 6 is fixedly installed on chassis 1, and engine 2 and cab 3 are fixedly installed on the upper side of frame 6 front sides , the peanut picking platform system is installed on the front side of the chassis 1, the peanut inclined conveying system is installed on the chassis 1 and located below the cab 3, the peanut fruit removal system is fixedly installed in the middle of the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com