Wheel type tube climbing robot for tube bank inspection

A robot and pipe climbing technology, applied in the direction of pipes/pipe joints/pipe fittings, special pipes, pipe components, etc., can solve the problems of difficult evaporation coils, areas that cannot be operated, and defrosting robots that cannot be installed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further described (be below with the direction that the wheeled pipe climbing robot of this row inspection is crawled longitudinally along the pipe as the front and back direction, with this row inspection with the wheeled pipe crawling robot laterally across the pipe crawling The direction is described as the left-right direction).

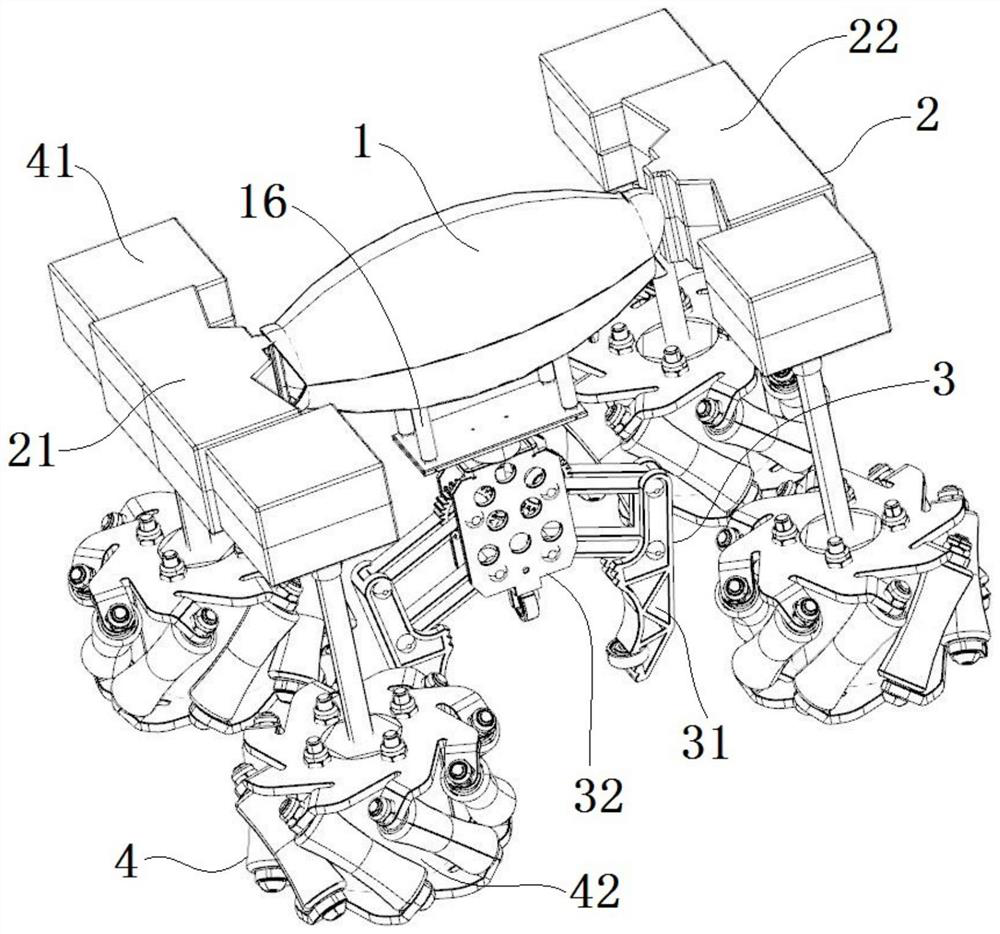

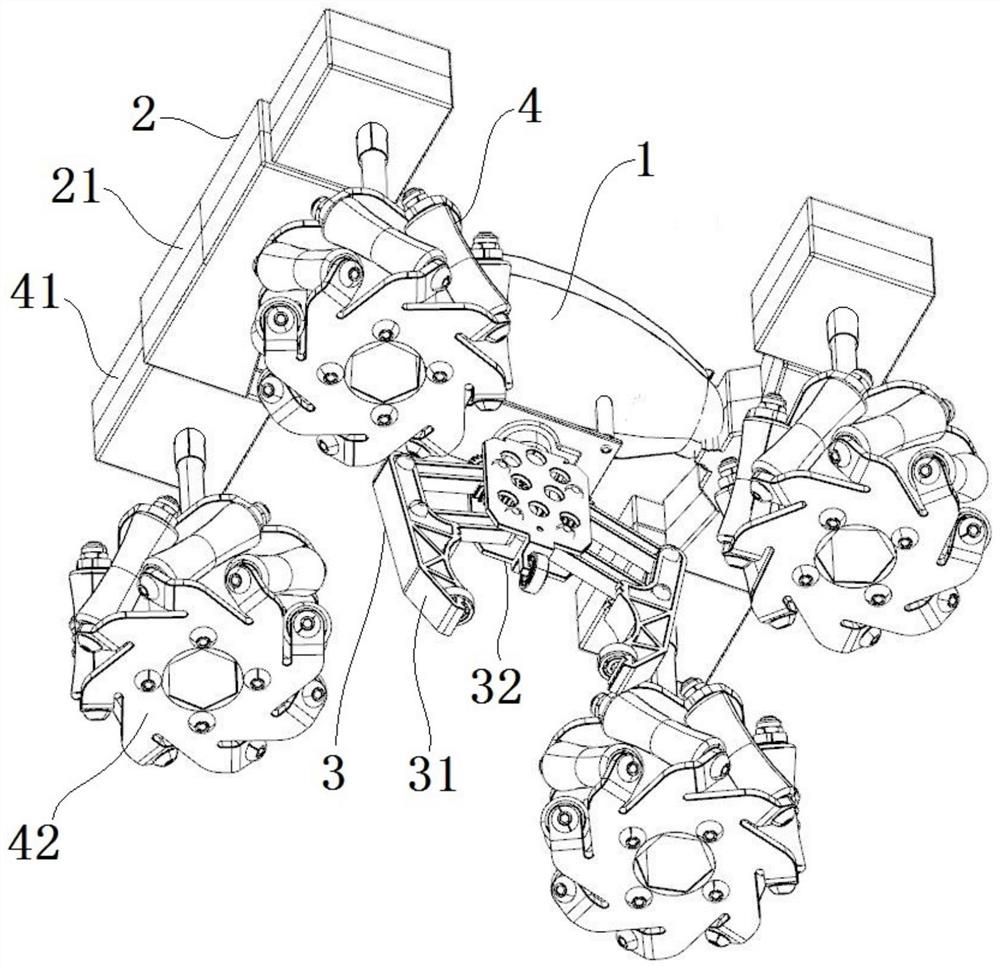

[0035] The wheeled pipe climbing robot for pipe inspection includes a base part, a lifting and clamping guide part, a clamping driving wheel part and a centralized electric control part.

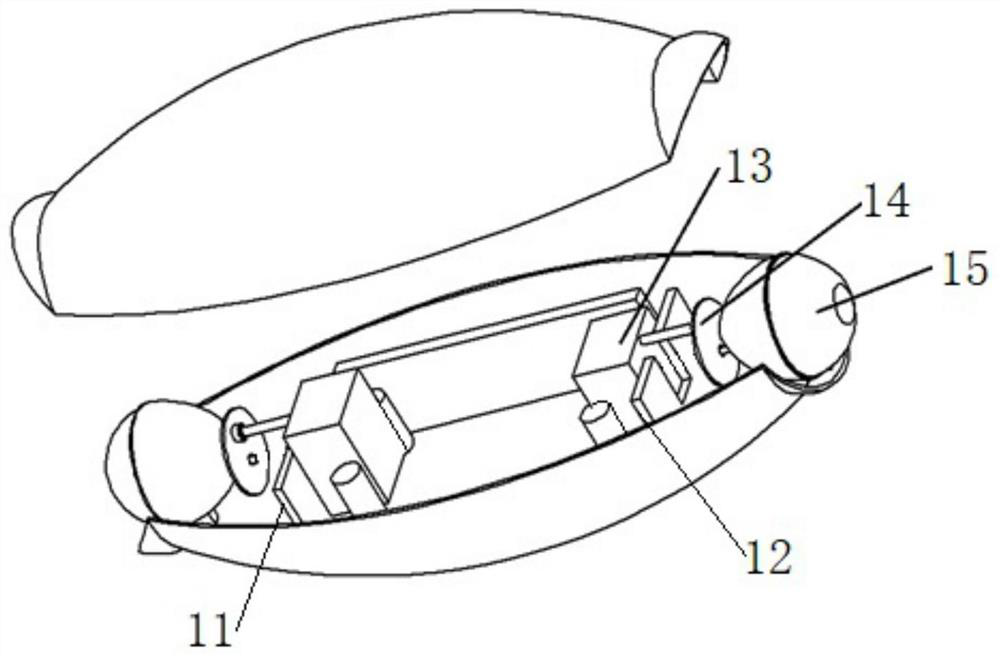

[0036] Such as figure 1 , figure 2 As shown, the base part includes a main base 1 and a sub-base 2; the main base 1 is at least one piece, and the sub-base 2 at least includes a left base 21 and a right base 22 symmetrically arranged with respect to the main base 1; the main base 1 is provided with a left and right base lifting control mechanism 11 and a right base lifting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com