Fire pump skid

A technology of fire pumps and hydraulic pumps, which is applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of high manufacturing and use costs, large floor space, etc., to reduce construction costs, improve power use efficiency, The effect of improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

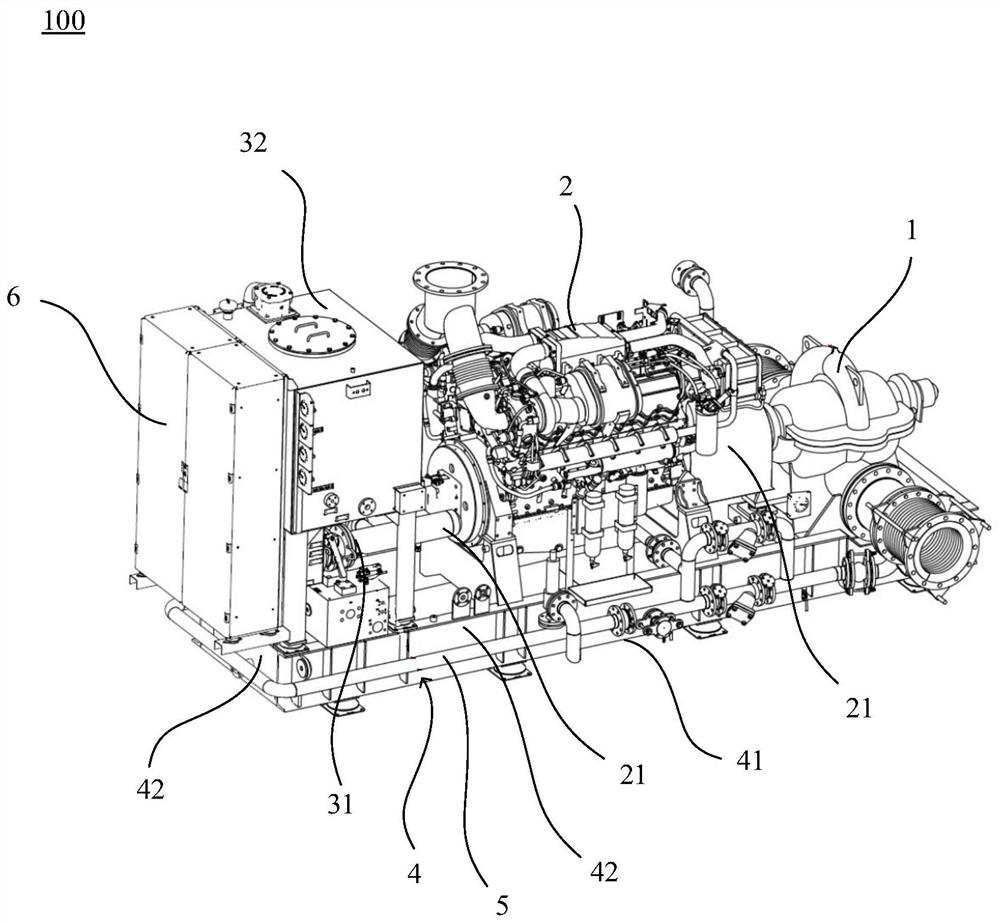

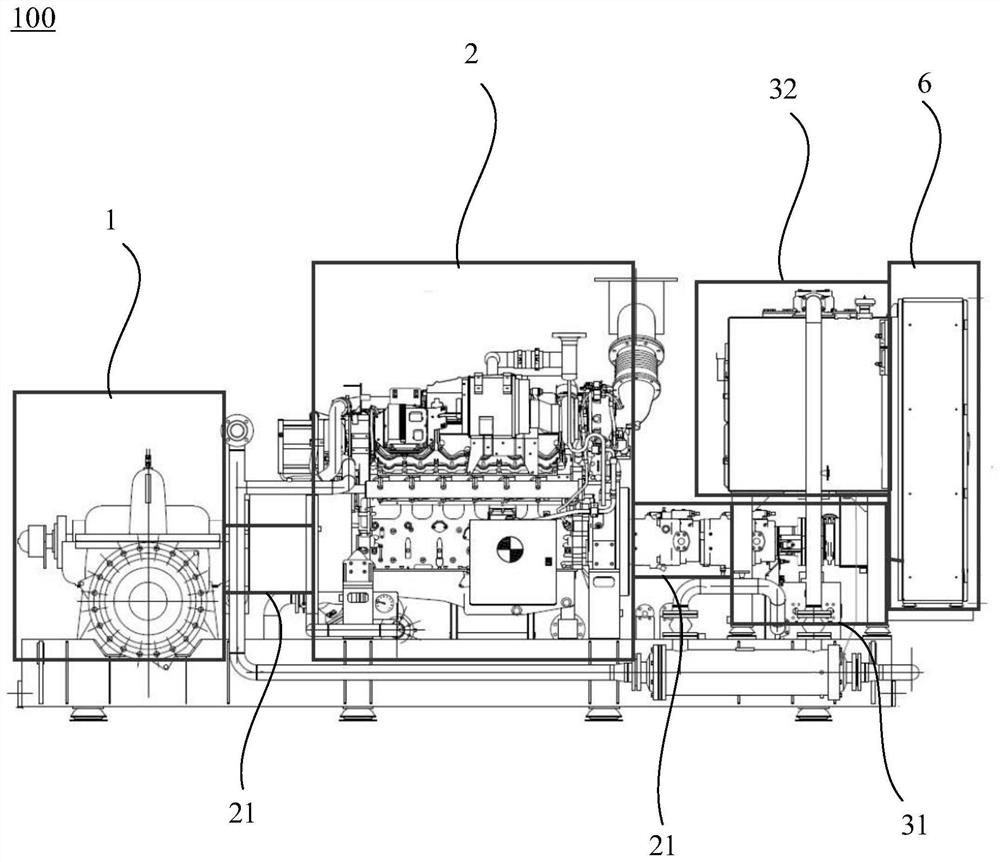

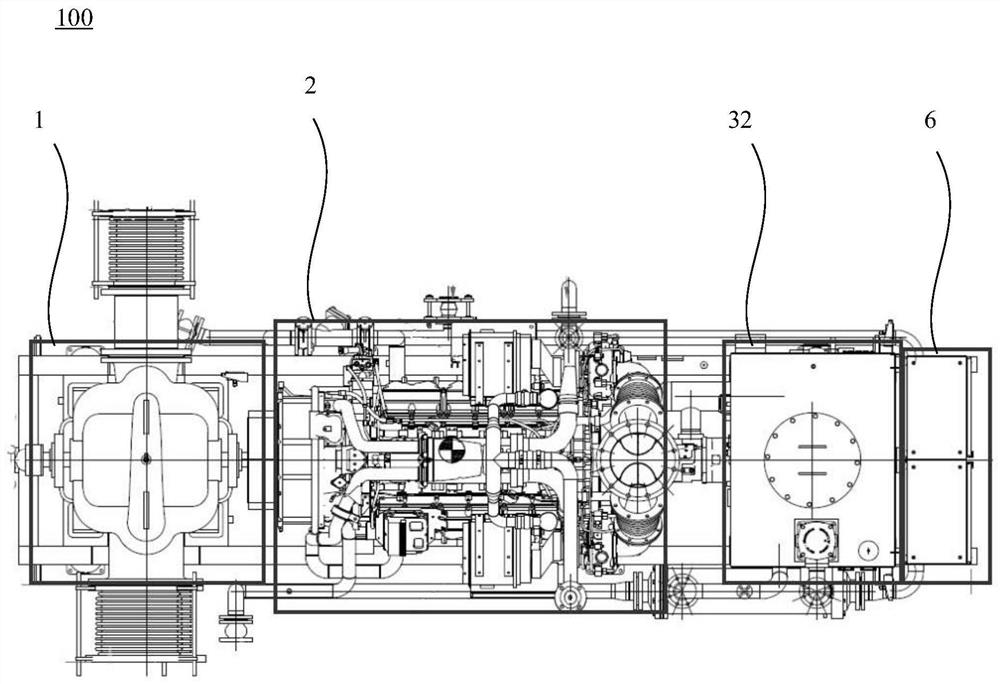

[0045] This embodiment provides a fire pump skid 100 . like Figure 1-3 As shown, the fire pump skid 100 includes a fire pump 1, a drive unit 2 and additional components. The drive unit 2 includes two output ends, one output end is connected to the fire pump 1 and provides driving force for the fire pump 1, and the other output end Connects to and provides driving force for additional components.

[0046] In this embodiment, the fire pump 1, the driving unit 2 and the additional components are designed in a reasonable skid layout, which improves the space utilization rate, provides more possibilities for the layout of the ship's cabin, and shortens the length of the pipeline. Save installation man-hours and reduce construction costs. In addition, both ends of the drive unit 2 are used simultaneously, one end drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com