Lifting and transverse moving three-dimensional parking equipment and using method thereof

A technology of three-dimensional parking, lifting and lateral movement, which is applied in the direction of the building, building type, building, etc. where the car is parked, to reduce the difficulty of use and avoid the effect of scratching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

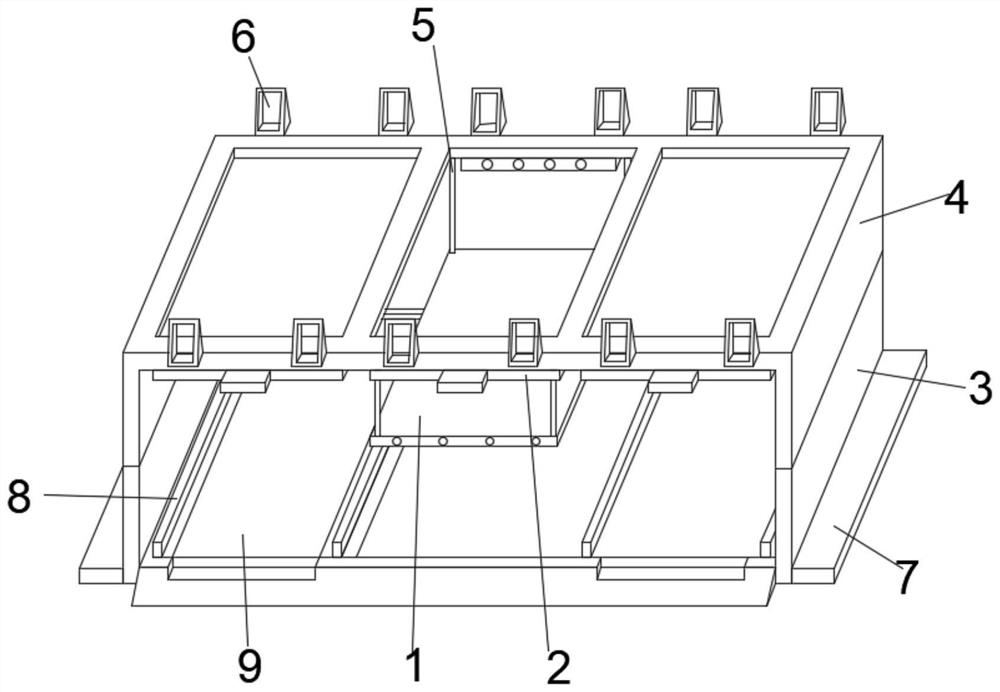

Embodiment 1

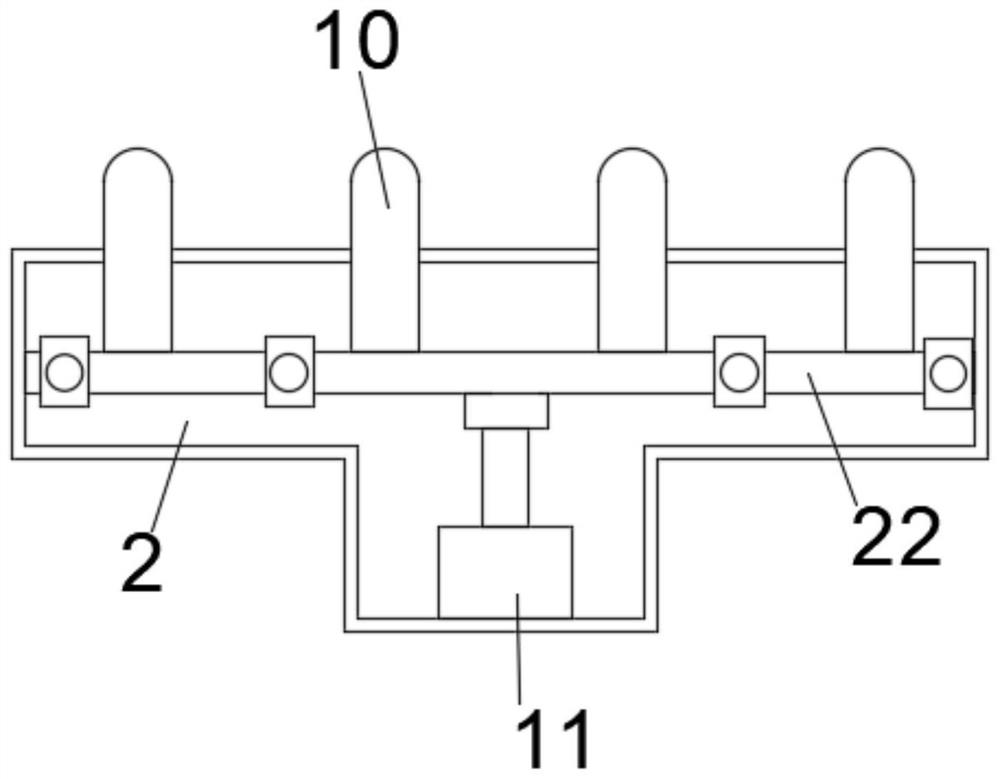

[0038] Four sets of positioning insert rods 10 are installed on the inner side of the limit ferrule 2, and one end of the positioning insert rod 10 is fixedly installed with a connecting rod 22. The outer surface of the other end of the positioning insert rod 10 is an arc structure, and the design of the arc structure It can reduce the resistance when the positioning insertion rod 10 is docked. When the lifting pallet 1 is in use, the traction cable 5 is rewound by the motor-driven runner, so that the traction cable 5 pulls the lifting pallet 1 to move upward. When the lifting pallet 1 is completed After the upward movement operation, the connecting rod 22 is driven by the electric push rod 11, so that the connecting rod 22 drives four sets of positioning inserting rods 10 to move at the same time, so that the positioning inserting rods 10 are inserted into the docking slot 13 of the lifting pallet 1, and the alignment is completed. The fixing operation of lifting pallet 1.

...

Embodiment 2

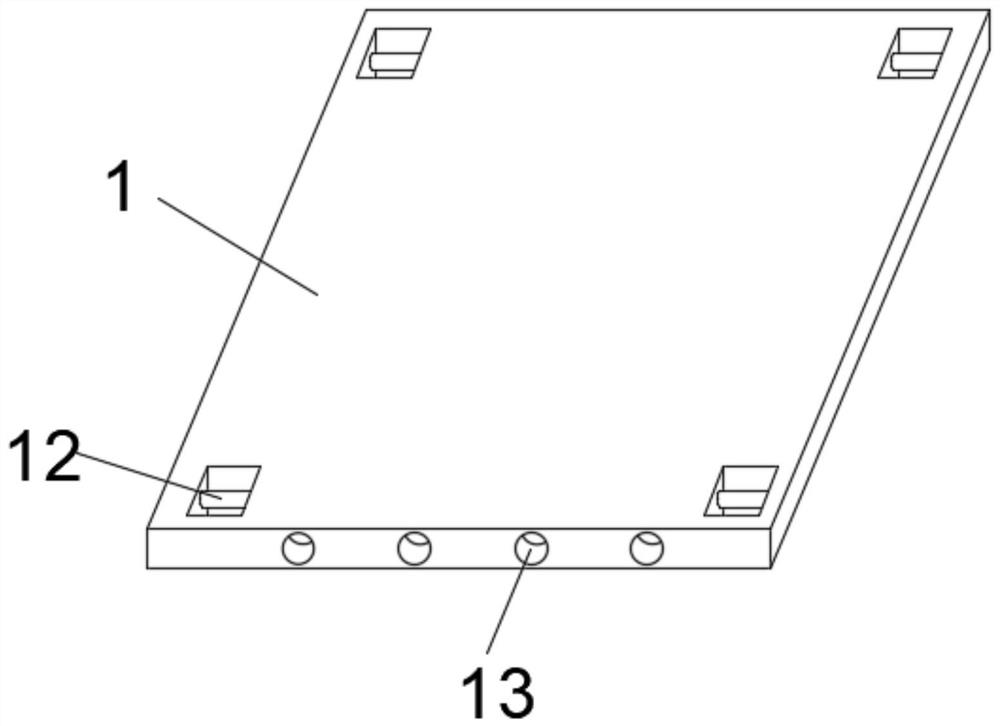

[0041] Four groups of traction steel cables 5 are arranged between the fixed top frame 4 and the lifting pallet 1, and the inner side of the lifting pallet 1 is provided with fixed bayonet pins 12 for docking the traction steel cables 5, and the two ends of the lifting pallet 1 are provided with Four groups of docking slots 13 utilize the setting of the fixed bayonet pin 12 to play a docking and fixing effect on the installation of the traction steel cable 5, and the docking slots 13 play a docking effect on the insertion of the positioning plunger 10 simultaneously.

[0042] Three groups of buffer pads 14 are fixedly installed on the outer surfaces of both sides of the traversing slide 8, and three sets of electric casters 15 are installed on the lower parts of both ends of the traversing slide 8, and the rotation of the electric casters 15 can be used to make the electric casters 15 Drive the traversing slide 8 to move, make the traversing slide 8 move laterally inside the fi...

Embodiment 3

[0045] The side of moving frame 19 is movably installed with docking frame 18, is connected by docking frame 18 between moving frame 19 and traversing slide seat 8, and the front end of rotating supporting plate 9 is movably installed with inclined rotating plate 20, and the length of docking frame 18 is greater than The length of the fixed base 3 is fixed, and the lower parts of both ends of the fixed base 3 are fixedly equipped with auxiliary support plates 7, which can effectively avoid the collision phenomenon between the rotating support plate 9 and the fixed base 3 during the rotation operation, and the docking frame 18 is driven by electric wheels Move the frame 19, so that the movable frame 19 and the rotating pallet 9 are moved out of the fixed base 3 at the same time, and the rotating pallet 9 is driven to rotate by the rotating clamp 21. When the vehicle enters the rotating pallet 9, the rotating pallet 9 is rotated and reset At the same time, use the electric wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com