Engine crankshaft forging die for hydrogen fuel cell hybrid power system

A hybrid power system and fuel cell technology, applied in the field of crankshaft forging, can solve problems such as the influence of the continuity of the crankshaft forging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

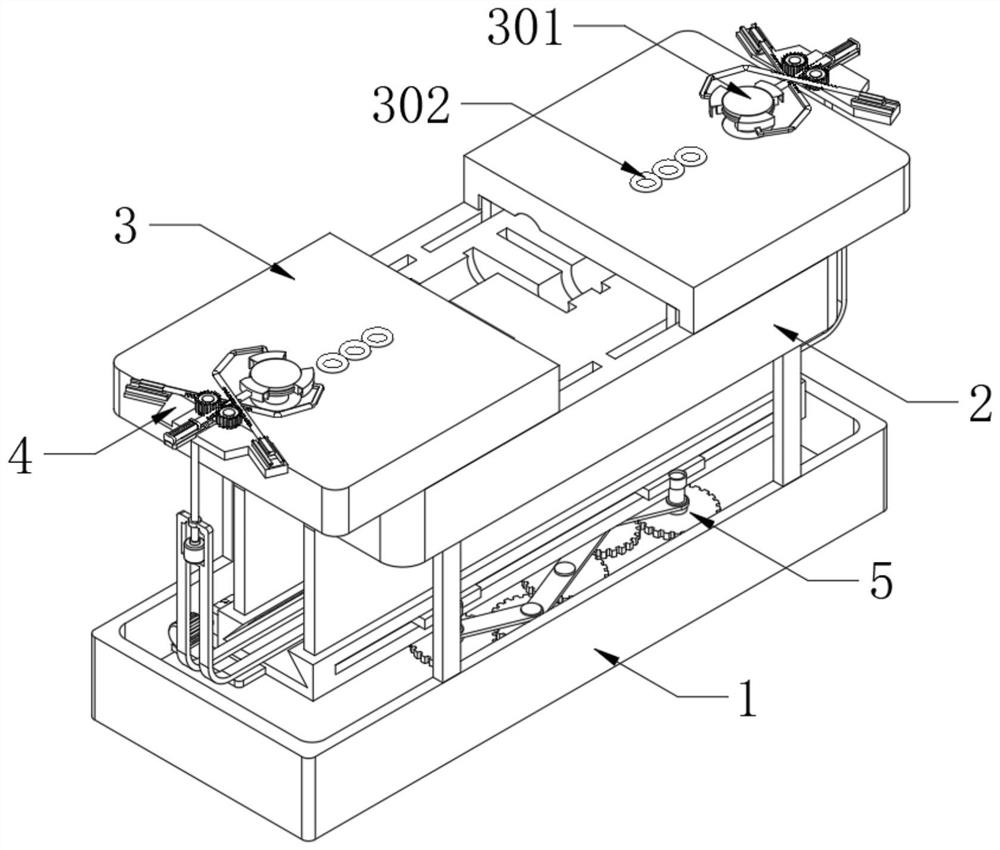

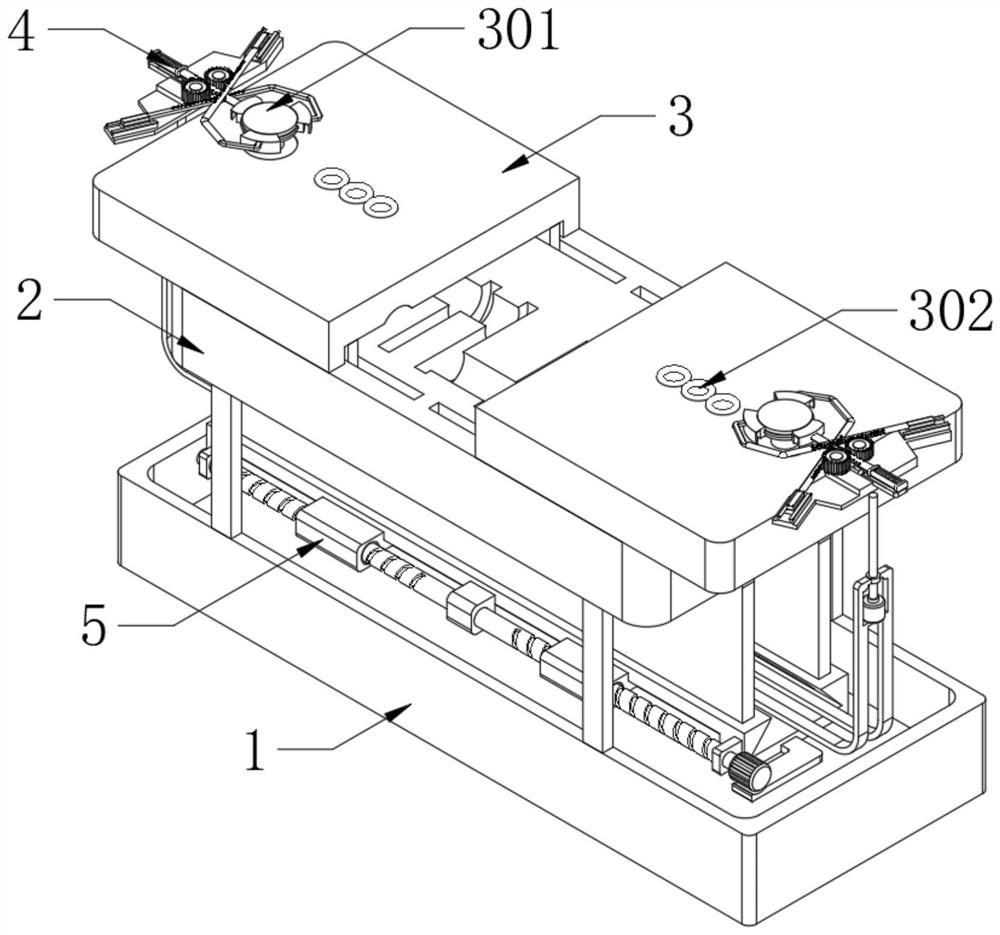

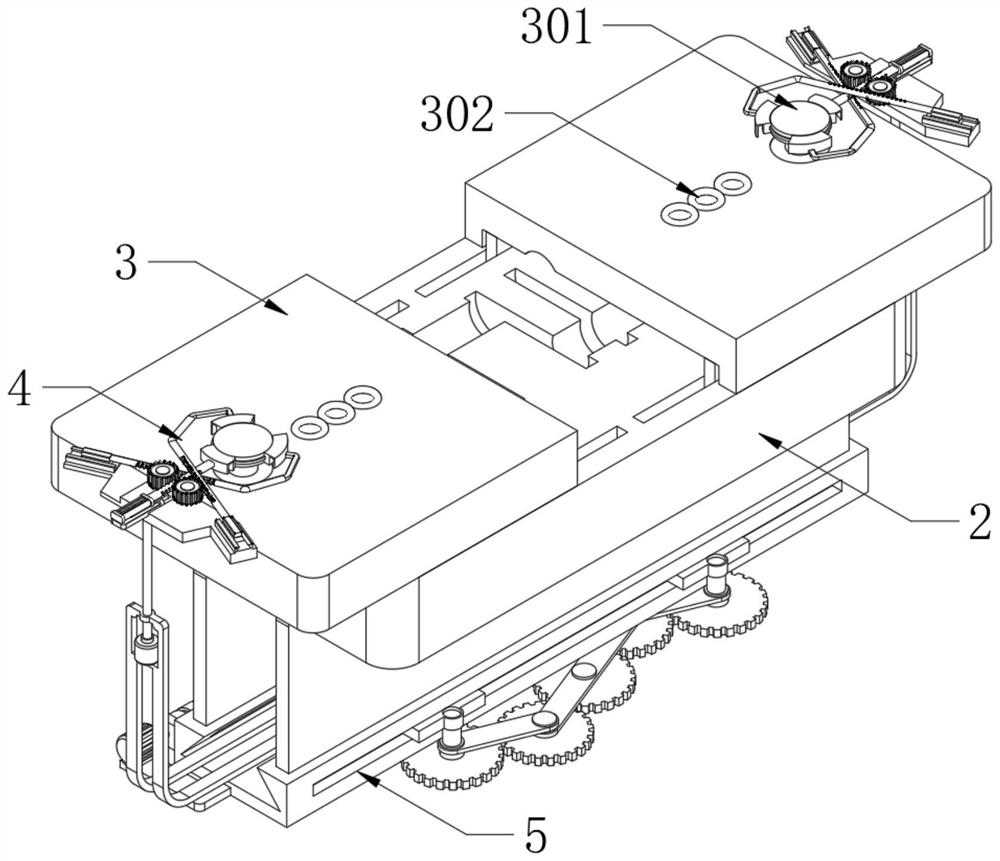

[0037] see Figure 1-3 , an engine crankshaft forging die for a hydrogen fuel cell hybrid power system, comprising an upper die 3 and a lower die 2, the upper die 3 is divided into two parts, the two parts of the upper die 3 are respectively movably connected with the upper side of the lower die 2, and the upper die 3 is provided with a sealable injection hole 302; the upper edge of the upper mold 3 is fixedly connected with a positioning column 301, and the outer side of the positioning column 301 is matched with a positioning component 4, and the lower side of the positioning component 4 is connected to the installation box 1 through a transverse adjustment member 5 above;

[0038] In the present invention, by setting the upper mold 3 and the lower mold 2, when the device is used for crankshaft forging, the required molding material is first poured into the forming groove of the lower mold 2, and then the lateral adjustment member 5 cooperates with the positioning assembly 4...

Embodiment 2

[0040] Such as Figure 4-8 As shown, the differences based on Embodiment 1 are:

[0041] The lateral adjustment member 5 includes a mounting rail 501, which is fixedly connected to the inner bottom surface of the mounting box 1, and the two ends of the lower side of the lower mold 2 are respectively fixedly connected to the upper side of the mounting rail 501 through a mounting plate; the mounting rail 501 is provided with a traverse groove 503, two traversing sliders 502 are slidably connected in the traversing groove 503;

[0042] The outer end of the traversing slider 502 is fixedly connected with a support plate 504, and the upper end of the support plate 504 is fixedly connected with an adjustment cylinder 505; The upper end of the plate 504 is slidingly connected;

[0043] An extension block A510 and an extension block B511 are fixedly connected to both sides of the traversing slider 502 respectively. Both sides of the installation rail 501 are provided with a through ...

Embodiment 3

[0050] Such as Figure 9-11 , based on Embodiment 1-2, the difference is:

[0051] The positioning assembly 4 includes a positioning slide rail A401, a positioning slide rail B402 and a positioning slide rail C403. The positioning slide rail A401, the positioning slide rail B402 and the positioning slide rail C403 are all fixedly connected to the mounting frame 6, and the lower side of the mounting frame 6 is fixedly connected to the The upper end of the adjustment cylinder 505; the upper side of the positioning slide rail A401, the positioning slide rail B402 and the positioning slide rail C403 are all slidably connected with the sliding block 404, the positioning slide rail C403 is fixedly connected with the drive cylinder 410, and the output end of the drive cylinder 410 is fixedly connected with a gear Bar bar 409; the lower side of the connection between the output end and the rack bar 409 is fixedly connected with a sliding part 4032, and the lower side of the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com