Duckbilled door handle and production process thereof

A production process and duckbill technology, applied in the field of duckbill door handles and their production processes, can solve problems such as unfavorable environmental protection, high cost, low efficiency, etc., and achieve the effects of saving labor, reducing labor costs, and improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

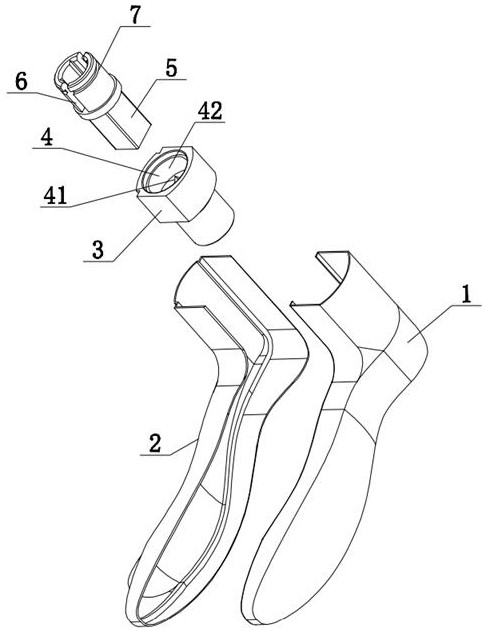

[0037] see figure 1 and 7 , a duckbill-shaped door handle, including an upper cover 1 and a lower cover 2, the edges of the upper cover 1 and the lower cover 2 are closely fitted by riveting, and the ends of the upper cover 1 and the lower cover 2 are installed with The universal head 3, the inside of the universal head 3 is provided with a socket 4.

[0038] see figure 1 , the lower half of the universal head 3 is set as cylindrical, and the upper half of the universal head 3 is provided with arcs on both sides. The inner side of each other fit together, so that the universal head 3 can be installed in the upper cover 1 and the lower cover 2 tightly.

[0039] see figure 1 , the socket 4 includes a rectangular opening 41 and a circular opening 42, the rectangular opening 41 is opened in the lower half of the universal head 3, and the circular opening 42 is opened in the upper half of the universal head 3, the said The rectangular opening 41 communicates with the circular ...

Embodiment 2

[0047] see Figure 6 , is another embodiment of this scheme. According to the needs of customers, movable heads 8 can also be installed at the ends of the upper cover 1 and the lower cover 2, and combined with the solution in Embodiment 1, it can be further improved in use. expanded scope of application.

Embodiment 3

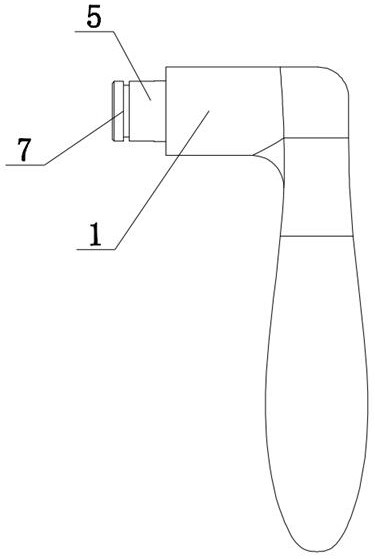

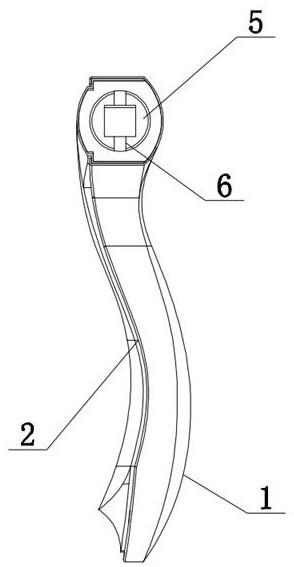

[0049] see Figure 2-5 , which is another embodiment of this solution, according to the needs of customers, a split head 5 can also be installed at the ends of the upper cover 1 and the lower cover 2, and the ends of the upper cover 1 and the lower cover 2 are provided with There is a split head 5, the upper side wall of the split head 5 is symmetrically provided with a vertical opening 6, the upper end of the split head 5 is provided with a ring groove 7, and the lower end of the split head 5 is set as a rectangle. body.

[0050] When in use, by setting the upper cover 1 and the lower cover 2, the upper cover 1 and the lower cover 2 are perfectly fitted by riveting, which greatly strengthens the structural strength of the entire door handle, and improves the appearance of the door handle. When in use, the handle of the door handle is improved, making it more comfortable for people to use. The universal head 3 installed inside the door handle is tightly connected to the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com