Hip joint implant with reshapeable fastening brackets

A technology of hip joints and implants, applied in the direction of joint implants, joint implants, hip joints, etc., which can solve problems that cannot be satisfactorily solved, lack of shape stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

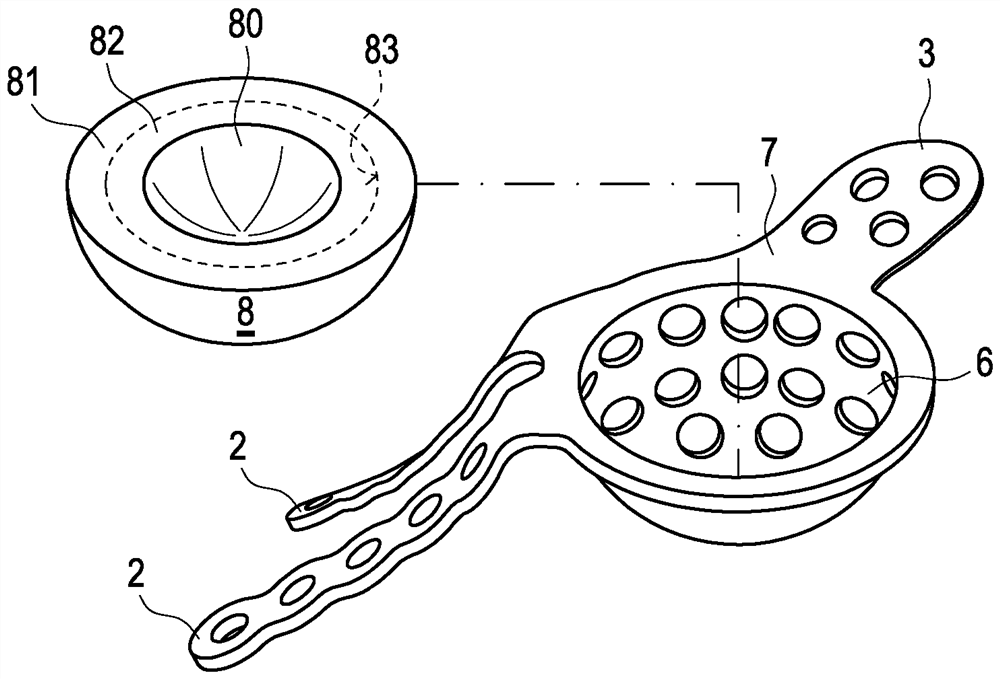

[0034] An embodiment of the hip implant according to the invention is in figure 1 The center is shown in the inserted state at the hip bone 9 (acetabulum).

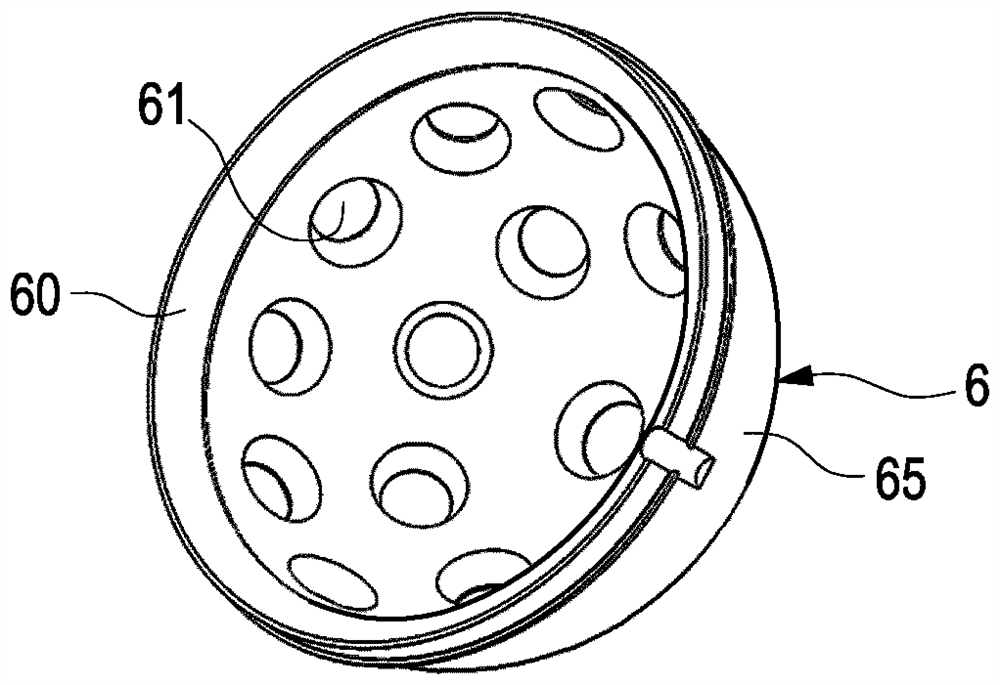

[0035] The hip joint implant is generally designated with reference numeral 1 and comprises a pot-shaped carrier 6 on which two flat and elongate fastening webs 2 are arranged pointing upwards (towards the cranium). On the pot-shaped carrier 6 (hereinafter also referred to as pot-shaped element for short), a shorter fastening web 3 extending downwards (towards the foot) is arranged opposite.

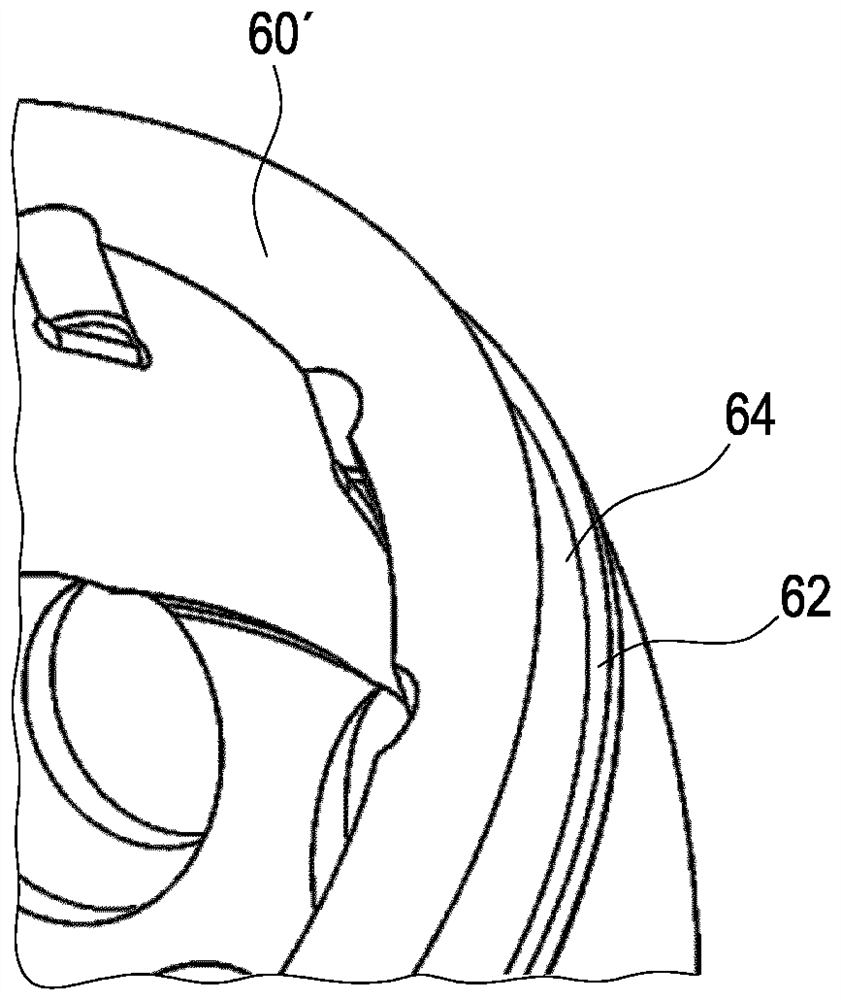

[0036] In the illustrated embodiment, the implant 1 consists of two parts, namely a pot 6 and a fixation part comprising fixation tabs 2, 3 and a fixation ring 4, the fixation tabs 2, 3 Arranged at the fixing ring. The fastening webs 2 are each elongated flat elements provided with a plurality of holes 21 for receiving fastening means. The fastening web 3 is likewise a flat element; however, in the exemplary embodiment shown it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com