Monitoring camera capable of avoiding influence of workshop steam atomization

A monitoring camera and steam technology, applied in the field of monitoring cameras, can solve the problems of dust spreading on the surface, affecting the video recording effect and clarity, affecting the normal operation of the camera, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

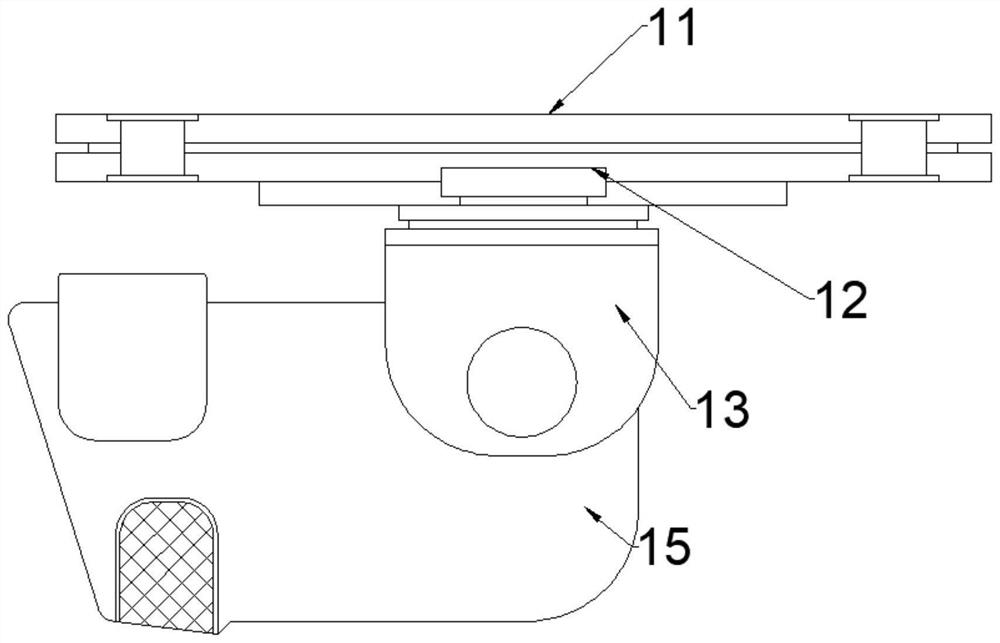

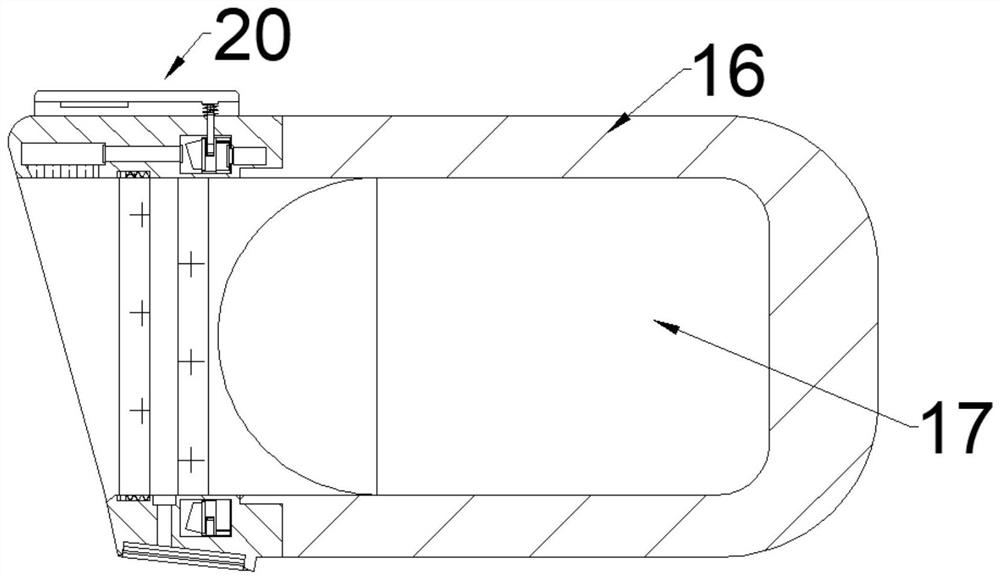

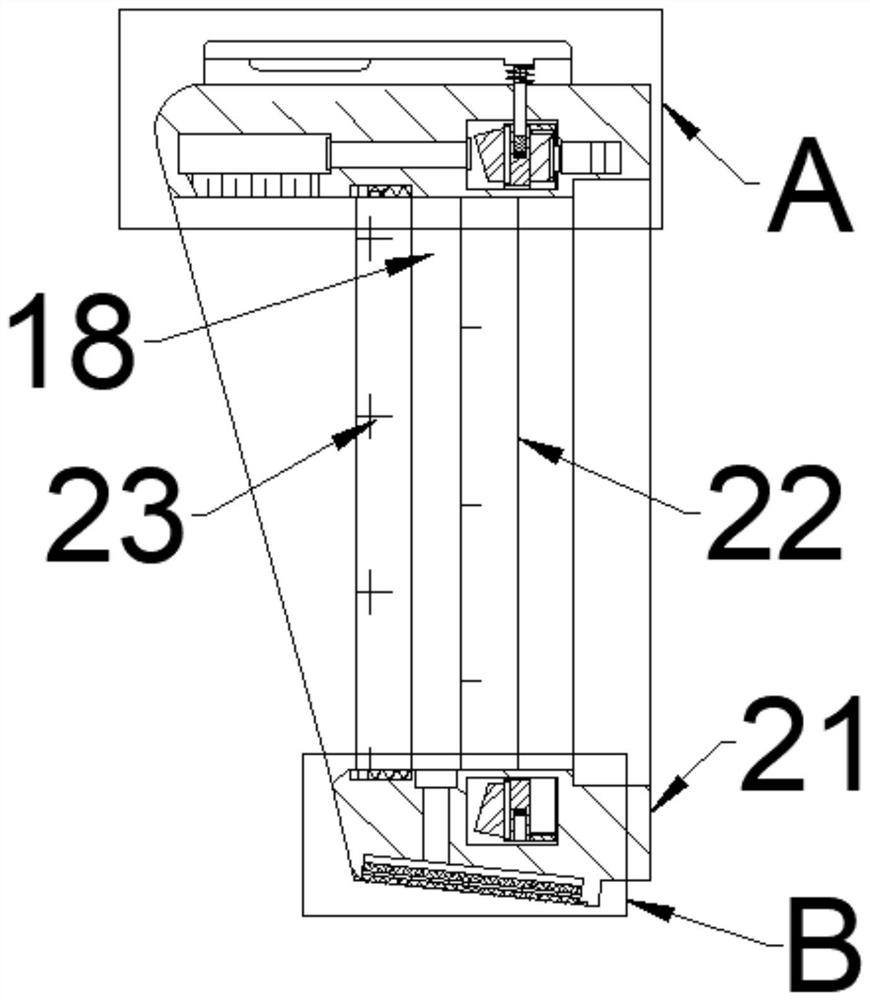

[0025] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0026] A monitoring camera for avoiding the influence of workshop steam atomization described in conjunction with accompanying drawings 1-6, includes a mounting fixture 11, and the mounting fixture 11 is rotatably mounted with a mounting frame 13, and the mounting frame 13 is equipped with a monitoring device 15 , the monitoring device 15 includes a carrying case 16, a monitoring module 17 is installed in the carrying case 16, and a steam treatment device 20 is detachably mounted on the carrying case 16, and the steam treatment device 20 includes a processing housing 21, the A fixed glass 22 is fixedly installed in the processing housing 21, an external glass sheet 23 is slidably inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com