External parameter calibration method and system for single-line laser radar and visible light camera

A single-line laser radar and calibration method technology, which is applied in image data processing, instruments, calculations, etc., can solve the problems of low calibration accuracy of external parameters of laser radar and cameras, and achieve the effects of high efficiency, simplified calibration process, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

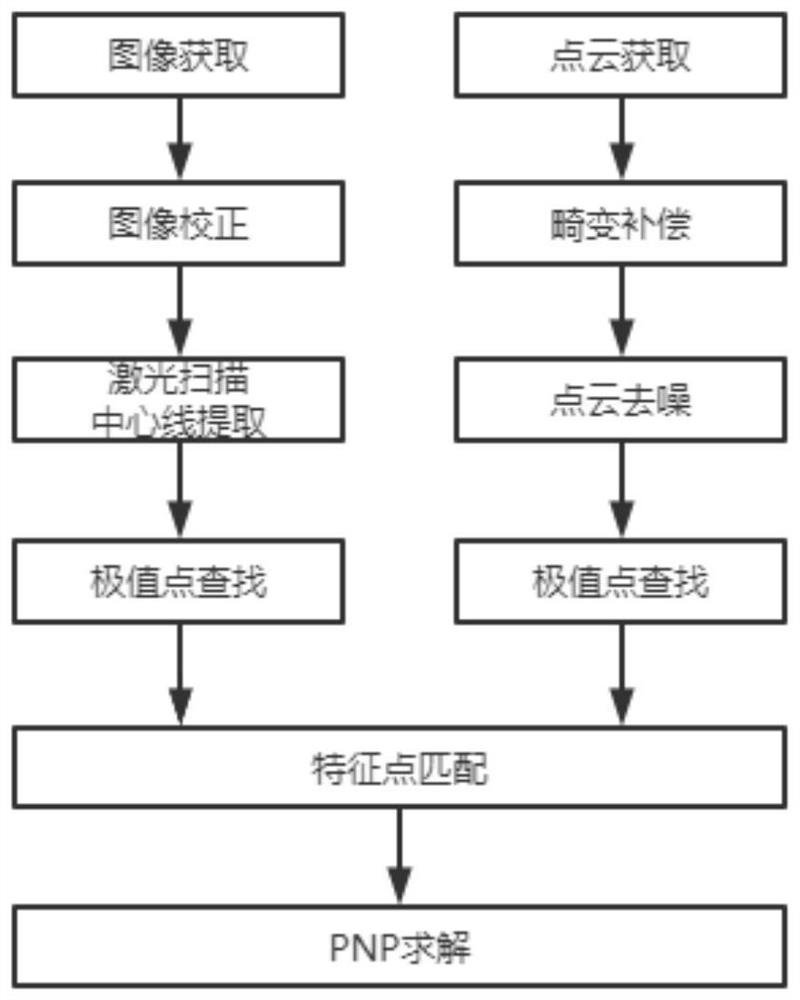

[0052] The external parameter calibration method of single-line laser radar and visible light camera provided by Embodiment 1 of the present invention includes:

[0053] Step S101, obtain multi-frame burden image data collected by visible light cameras and multi-frame point cloud data collected by single-line lidar in the same time period, and realize single-frame furnace burden image and single-frame point cloud according to the time difference threshold and point cloud data volume threshold Time matching of data;

[0054] Step S102, establishing a camera distortion model, and correcting the burden image according to the camera distortion model;

[0055] Step S103, extracting the laser scanning center line according to the corrected charge image, and determining the two-dimensional coordinates corresponding to the local extremum of the laser scanning center line in the image coordinate system;

[0056] Step S104, interpolating the sparse point cloud data according to the ste...

Embodiment 2

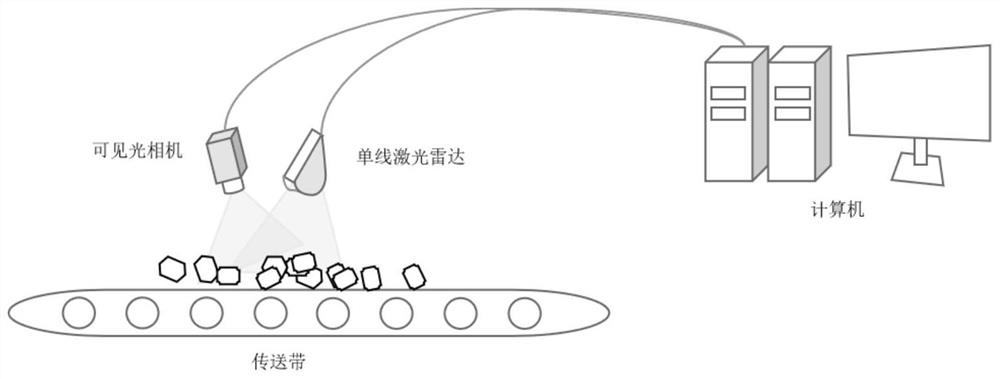

[0062] refer to figure 1 , figure 1 It is a schematic diagram of a particle size detection system installed on a blast furnace burden conveyor belt according to an embodiment of the present invention, including a single-line laser radar, a visible light camera, and a computer.

[0063] refer to figure 2 The method for calibrating external parameters of a single-line laser radar and a visible light camera provided in Embodiment 2 of the present invention includes the following steps:

[0064] (1) Use an industrial camera to obtain the image of the furnace charge ore on the conveyor belt, scan the surface of the furnace charge through a single-line laser radar to form point cloud data, and perform time matching between the single frame image and the single frame point cloud data according to the time constraint relationship and the number of point clouds.

[0065] (2) Establish the camera imaging model and distortion model, use the Zhang Zhengyou checkerboard calibration meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com