Method and device for testing wettability of battery cell pole group

A test method and a test device technology, which are applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as poor wetting effect of pole pieces, serious stress on batteries, abnormal center of pole pieces, etc., so as to facilitate technical realization and facilitate Observation and control of flow rate, effect suitable for test requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention relates to a method for testing the wetting performance of an electrode group of an electric core. The method provides a parameter standard for characterizing the performance of an electrode group infiltrated with an electrolyte solution and the method steps for obtaining the test.

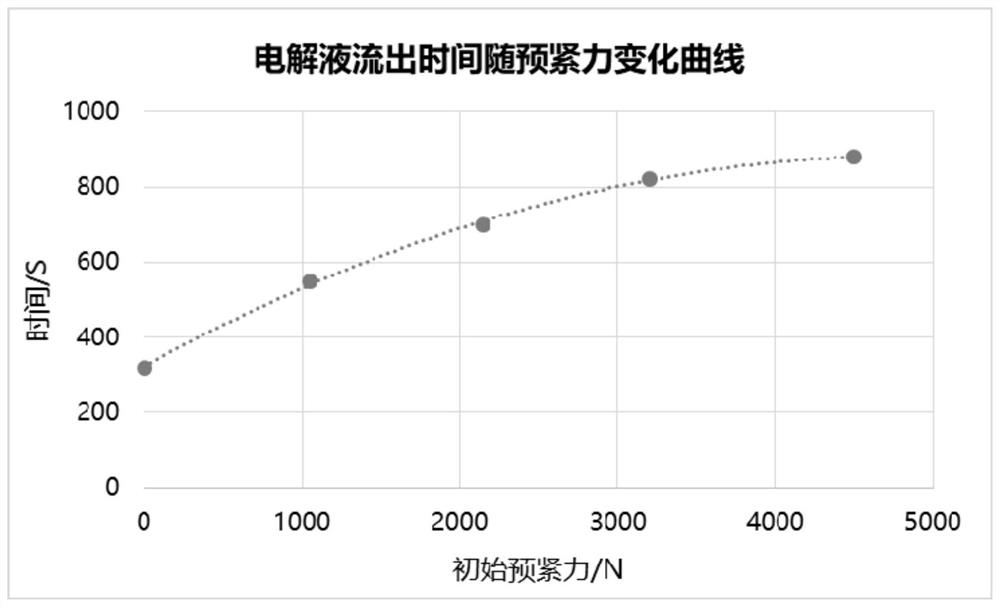

[0036] On the whole, in the test method of the wettability of the cell electrode group, firstly, the cell electrode group is placed under the simulated extrusion condition with the pre-tightening force K set. Afterwards, the electrolyte was dripped into the cell electrode assembly from above the cell electrode assembly at a constant flow rate, and the time T1 at which the dripping started was recorded. After that, observe the time for the electrolyte to flow out from the bottom of the cell electrode group, and record this time as T2. Finally, the difference between T2 and T1 is used as the outflow time ΔT to characterize the wetting performance of the cell electrode group unde...

Embodiment 2

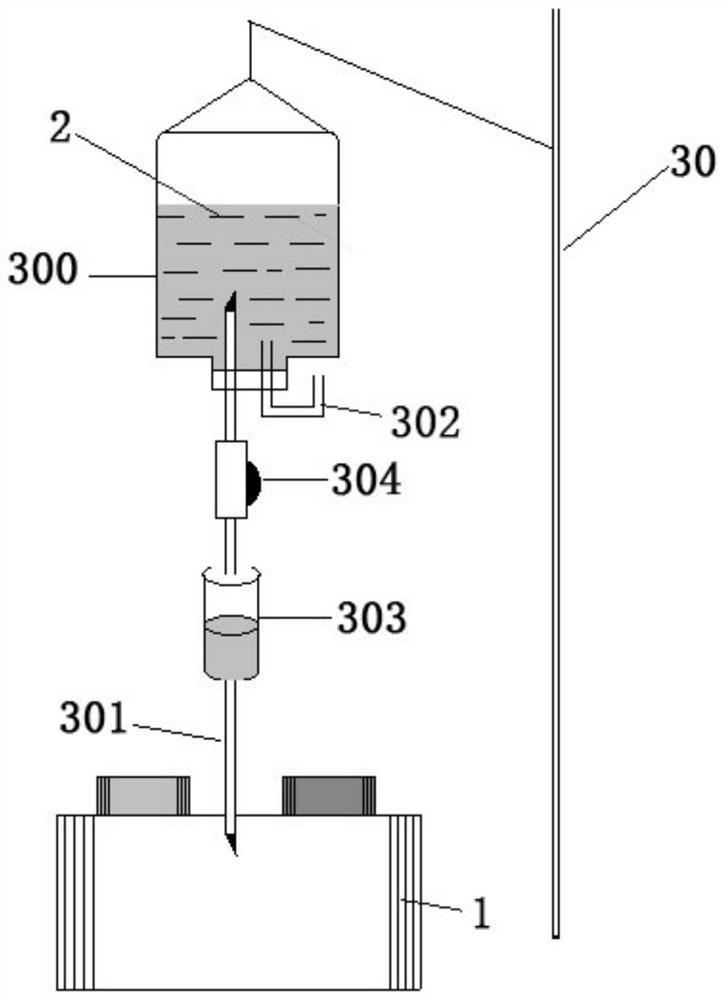

[0055] The present invention relates to a test device for the wetting performance of the battery electrode group. The test device is set based on the test method for the wetting performance of the battery electrode group provided in Embodiment 1. An exemplary structure thereof is as follows image 3 As shown, it mainly includes an extrusion platform for simulating the extrusion working conditions of the cell electrode group 1, and a dripping device arranged above the extrusion platform.

[0056] Among them, two pressure plates with adjustable spacing are arranged on the extrusion platform, and the two pressure plates can fix the cell electrode group 1, and the extrusion force given to the cell electrode group 1 by the two pressure plates can be changed through adjustment. The pressure plate is adopted, and the clamping force of the pressure plate can be adjusted through guiding, locking and other structures. It has the advantages of simple structure, convenient construction, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com