Novel foamed concrete, foamed concrete prefabricated part and preparation method of light filling cast-in-place wall

A new technology of foamed concrete, which is applied in the preparation of foamed concrete prefabricated parts and lightweight filled cast-in-place walls, in the field of foamed concrete, can solve the problems of low concrete construction efficiency and high production cost, and achieve reuse, Low production cost, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

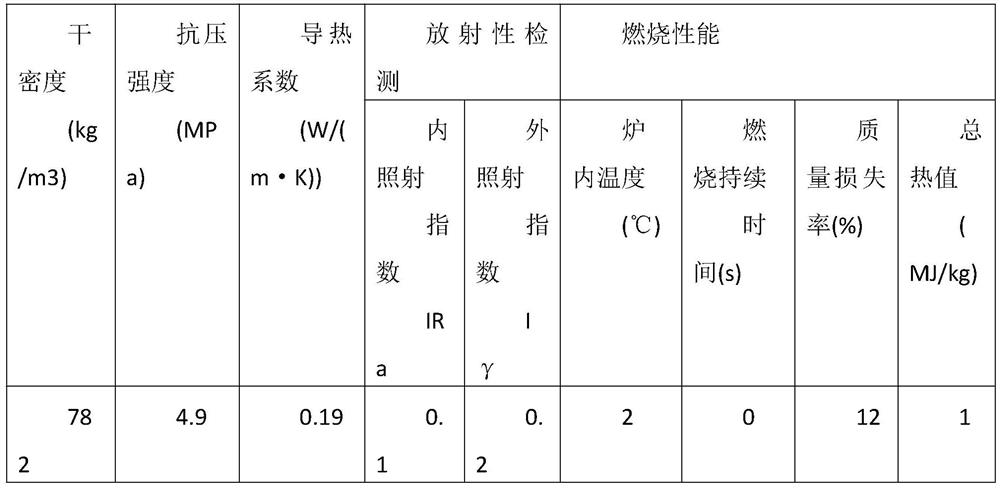

Embodiment 1

[0040] A method for preparing a lightweight filled cast-in-place wall, comprising the steps of:

[0041] S1, in parts by mass, add 200 parts of cement, 300 parts of stone powder, 300 parts of slag, 10 parts of admixture, and 120 parts of water into a mixer and stir evenly to obtain a mixture;

[0042] S2, after stirring evenly, put the mixture into the mixer truck and transport it to the construction site for pouring;

[0043] S3, according to the working conditions, use the reusable shaped plastic formwork to carry out the assembly and shaping of the process-oriented mold, and reinforce the shaped mold with pins;

[0044] S4, add 0.1 part of foaming agent in parts by mass to the mixture, avoid vibration, after foaming, pour it into the previously established mold through the delivery pump to form. Wherein, foaming agent is sodium lauryl sulfate.

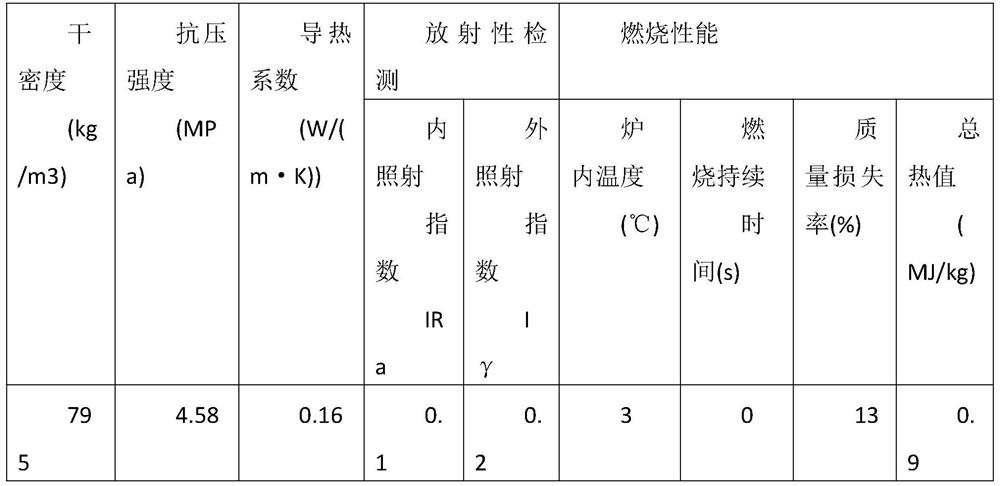

Embodiment 2

[0046] A method for preparing a lightweight filled cast-in-place wall, comprising the steps of:

[0047] S1, in parts by mass, add 200 parts of cement, 500 parts of slag, 12 parts of admixture, 130 parts of water, and 100 parts of fly ash into a mixer and stir evenly to obtain a mixture;

[0048] S2, after stirring evenly, put the mixture into the mixer truck and transport it to the construction site for pouring;

[0049] S3, according to the working conditions, use the reusable shaped plastic formwork to carry out the assembly and shaping of the process-oriented mold, and reinforce the shaped mold with pins;

[0050] S4, adding 0.25 parts of foaming agent in parts by mass to the mixture, avoiding vibration, pouring into the previously erected mold by a delivery pump after foaming to form. Wherein, foaming agent is sodium lauryl sulfate.

Embodiment 3

[0052] A method for preparing a lightweight filled cast-in-place wall, comprising the steps of:

[0053] S1, in parts by mass, add 200 parts of cement, 10 parts of admixture, 200 parts of stone powder, 130 parts of water, 250 parts of slag, and 150 parts of fly ash into a mixer and stir evenly to obtain a mixture;

[0054] S2, after stirring evenly, put the mixture into the mixer truck and transport it to the construction site for pouring;

[0055] S3, according to the working conditions, use the reusable shaped plastic formwork to carry out the assembly and shaping of the process-oriented mold, and reinforce the shaped mold with pins;

[0056] S4, add 0.2 parts of foaming agent by mass to the mixture, avoid vibration, after foaming, pour into the previously established mold by delivery pump to form. Wherein, foaming agent is sodium lauryl sulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com