Connecting structure of moving cutter for shaver and cutter head assembly

A connection structure and technology of hair shavers, which are applied to the connection structure of a moving knife for hair shavers and the field of cutter head components, can solve problems such as affecting the cutting sharpness of the moving knife, affecting the shaving sharpness of the moving knife, and the installation deformation of the moving knife. , to achieve the effect of improving shaving efficiency and use comfort, high assembly efficiency, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

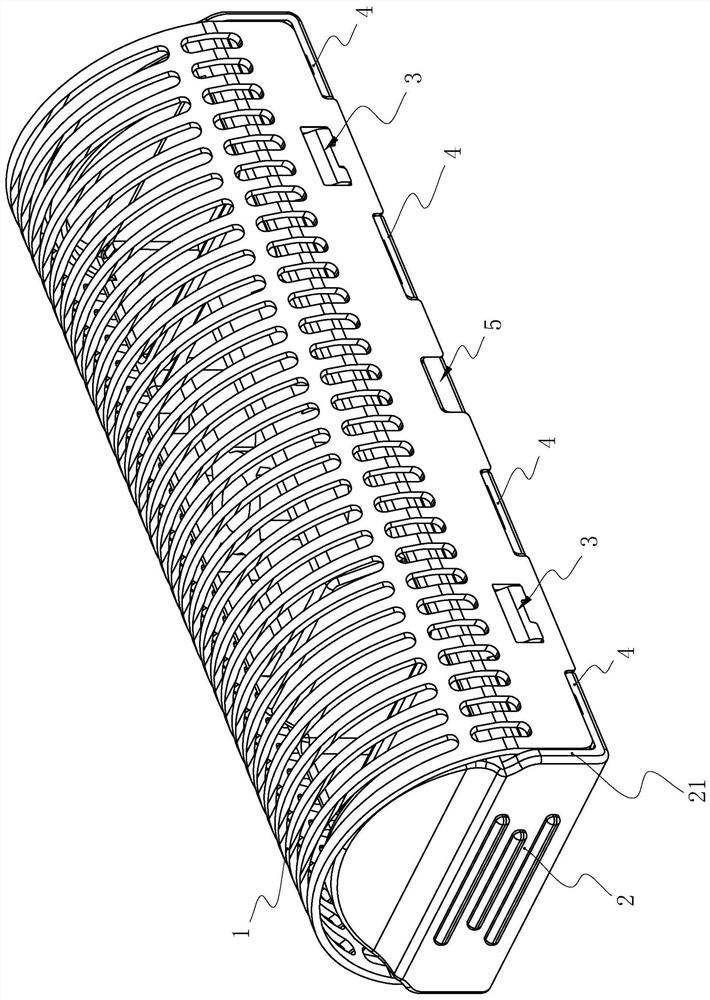

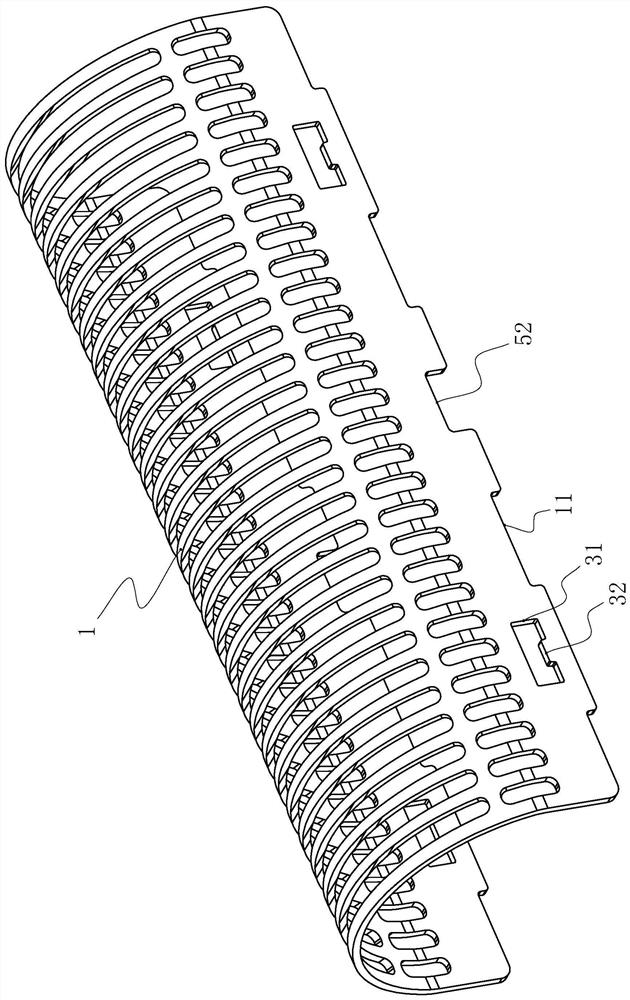

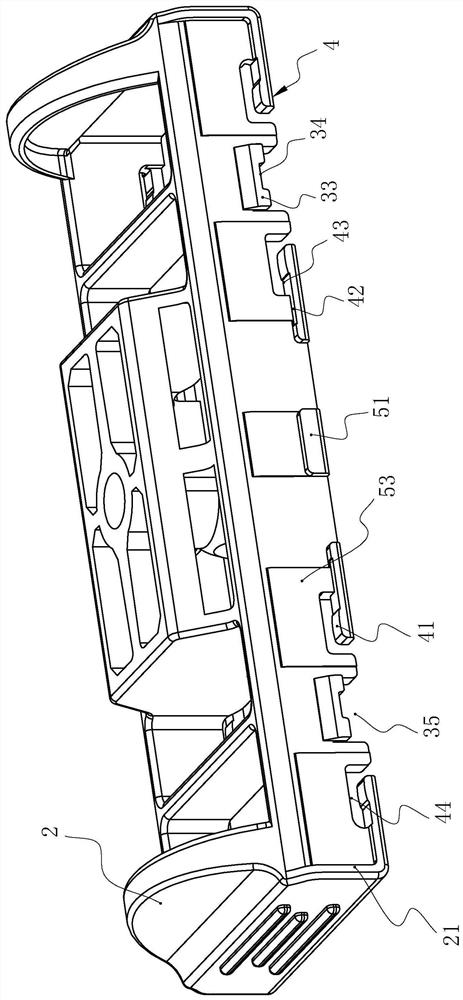

[0026] Such as Figure 1-3 As shown, the present invention is a connection structure of a moving knife for a shaver, including a moving knife 1 and a moving knife seat 2; The knife 1 is in contact with the elastic tongue piece 4 arranged on the movable knife seat 2 at the same time, and the elastic tongue piece 4 can automatically reset and synchronously drive the movable knife 1 to move upward when subjected to an external force. The movable knife 1 and the movable knife seat 2 are fixed by the buckle mechanism 3. The buckle mechanism 3 not only facilitates production and processing, but also has simple operation and high assembly efficiency during the assembly process, and can effectively reduce production costs. Secondly, when the snap connection between the movable knife 1 and the movable knife seat 2 is too tight, the assembly deformation of the movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com