Locomotive side wall filter

A filter and side wall technology, which is applied in the field of locomotive side wall filters, can solve the problems of inability to filter, reduce the filtering effect, and hardening, and achieve the effect of increasing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

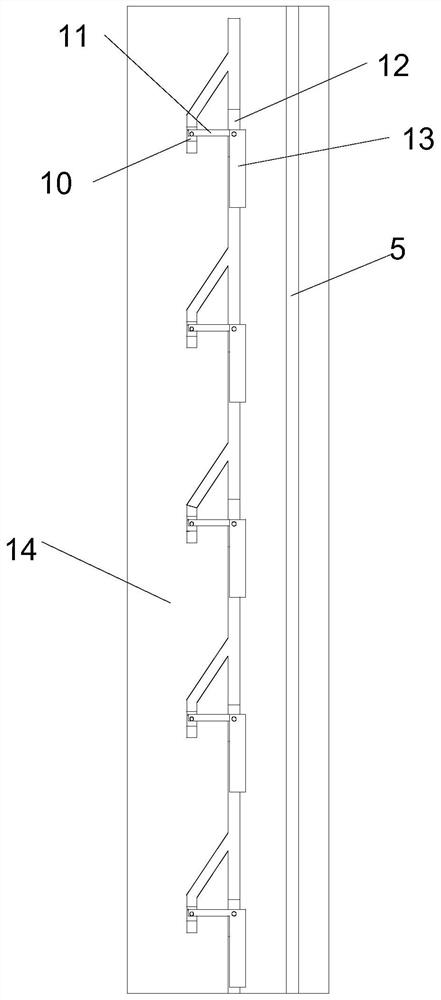

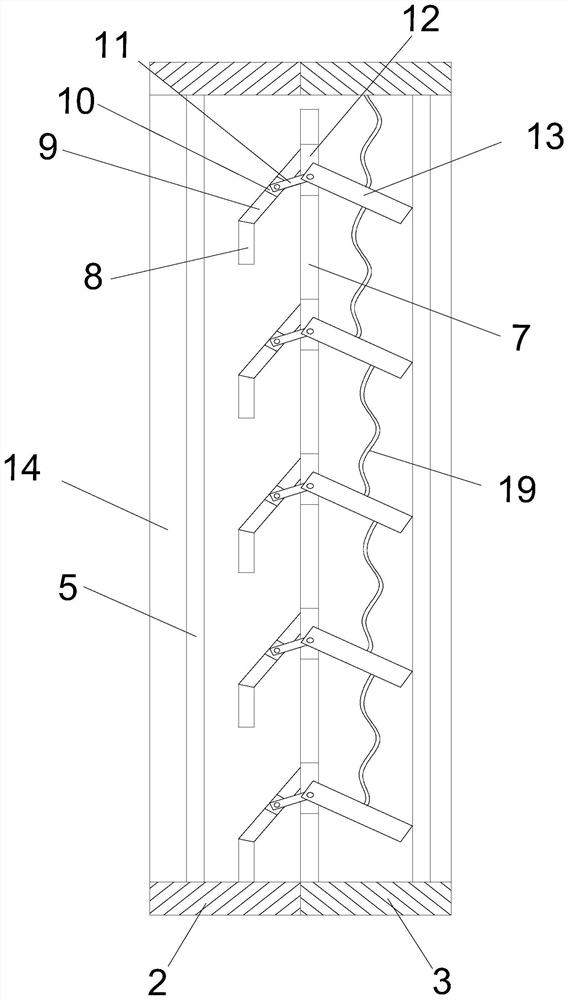

[0033] Please refer to Figure 1-Figure 5 as shown, figure 1 It is a schematic diagram of the main structure of the present invention; figure 2 It is a schematic diagram of the initial structure of the cleaning assembly in the present invention; image 3 It is a schematic diagram of the deformation structure of the cleaning assembly in the present invention; Figure 4 It is a structural schematic diagram of the fixed plate 14 and the driving assembly in the present invention; Figure 5 It is a schematic diagram of the three-dimensional structure of the present invention.

[0034]The embodiment of the present application provides a locomotive side wall filter, including the first frame 2 and the second frame 3 spliced by the first frame 2, and the area surrounded by the first frame 2 and the second frame 3 is provided with two A metal filter screen 18, any one metal filter screen 18 is provided with a first filter screen 4 on the side away from another metal filter scree...

Embodiment 2

[0037] Please refer to Figure 1-Figure 5 as shown, figure 1 It is a schematic diagram of the main structure of the present invention; figure 2 It is a schematic diagram of the initial structure of the cleaning assembly in the present invention; image 3 It is a schematic diagram of the deformation structure of the cleaning assembly in the present invention; Figure 4 It is a structural schematic diagram of the fixed plate 14 and the driving assembly in the present invention; Figure 5 It is a schematic diagram of the three-dimensional structure of the present invention.

[0038] In some embodiments of the present invention, the cleaning assembly includes a fixed plate 14, and the fixed plate 14 is vertically installed in the area surrounded by the first frame 2 and the second frame 3, and the side wall of the fixed plate 14 is vertically Direction is provided with guide groove 7, and the sidewall of fixed plate 14 is provided with the limit groove 9 that is communicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com