Interferometer device and method for producing an interferometer device

A technology of interferometer and filter device, which can be used in interferometric spectroscopy, measurement devices, instruments, etc., and can solve problems such as reducing the robustness of spectrometers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the figures, identical reference numbers designate identical or functionally identical elements.

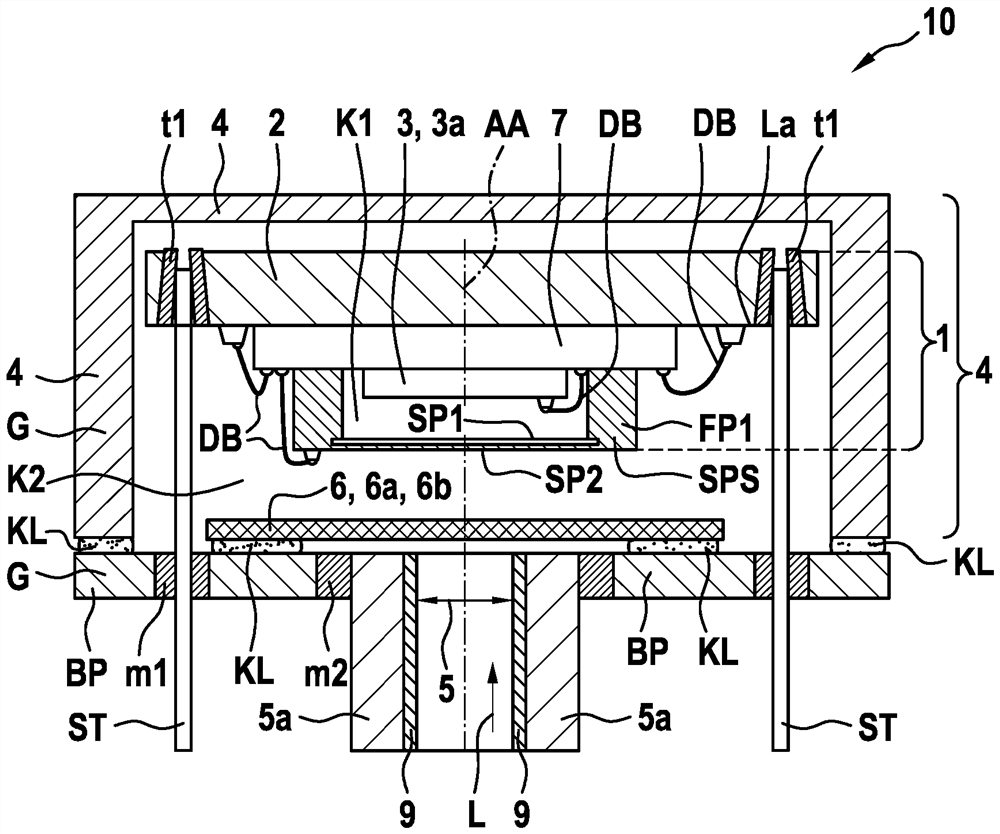

[0036] figure 1 A schematic side view of an interferometer arrangement according to an exemplary embodiment of the invention is shown.

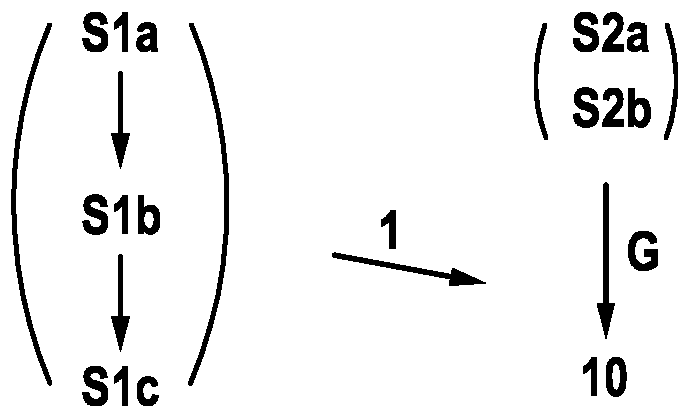

[0037]The interferometer device 10 comprises an interferometer unit 1 with: a base substrate 2 comprising electrical conductor connections La; a Fabry-Perot-unit FPI, the Fabry-Perot - the cells are arranged on the base substrate 2 and form a first cavity K1 in the region of the base substrate 2 and are connected to the electrical conductor connection La; and a detector device 3 , which It is arranged on the base substrate 2 and in the first cavity K1 between the base substrate 2 and the interferometer unit 1 and is connected to the electrical conductor connection La. Furthermore, the interferometer device 10 comprises a housing G which comprises a base plate BP and a cover structure 4 , wherein the cover structure 4 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com