Feeding control system and control method for chinlon chip raw materials

A technology for controlling systems and raw materials, applied in chemical instruments and methods, dissolving, loading/unloading, etc., can solve problems such as troublesome feeding operations, oxidative scrapping of raw materials, misjudgment, etc., to avoid exposure to oxidation, avoid mutual cross-contamination, operation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

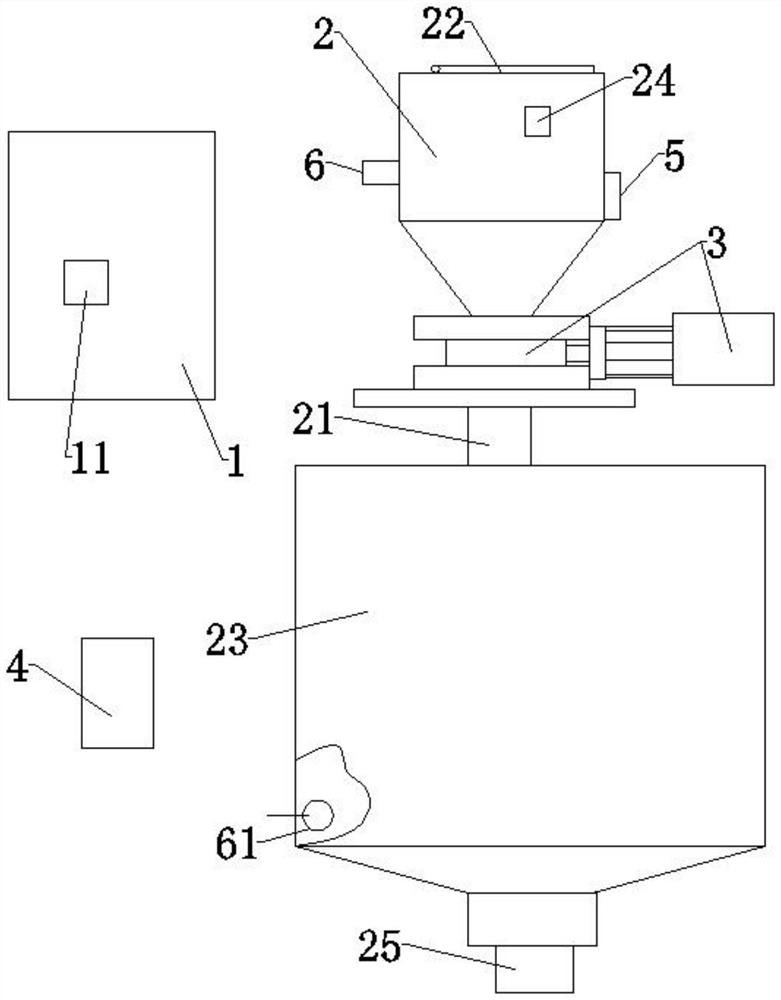

[0038] see figure 1 As shown, the present invention provides a technical solution: a feeding control system for nylon chip raw materials, including:

[0039] The feeding box 2 is a feeding device for nylon slicing raw materials. The top is provided with a feeding warehouse cover 22, which is provided with a feeding identification code 24, and the bottom is provided with a feeding port 21 for raw materials to enter the storage process. A feed bin 23 with a fixed capacity is connected to the bottom of the feeding port 21;

[0040] The feed identification code 24 is matched with the data of the corresponding feed bin 23, and each feed bin 23 is in one-to-one correspondence with a feed identification code 24;

[0041] The automatic valve 3 is installed on the feeding port 21;

[0042] The raw material bag 1 is a sealed bag containing a fixed amount of nylon chip raw material, on which a raw material identification code 11 is provided, and the identification code 11 matches the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com