Rapid feeding device and feeding method for injection molding equipment

A technology of injection molding equipment and material suction device, which is applied in the field of rapid feeding device of injection molding equipment, can solve the problems of high labor intensity, small packaging capacity, waste of site area, etc., so as to improve the qualified rate of products, reduce the number of feeding times, and reduce inventory. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

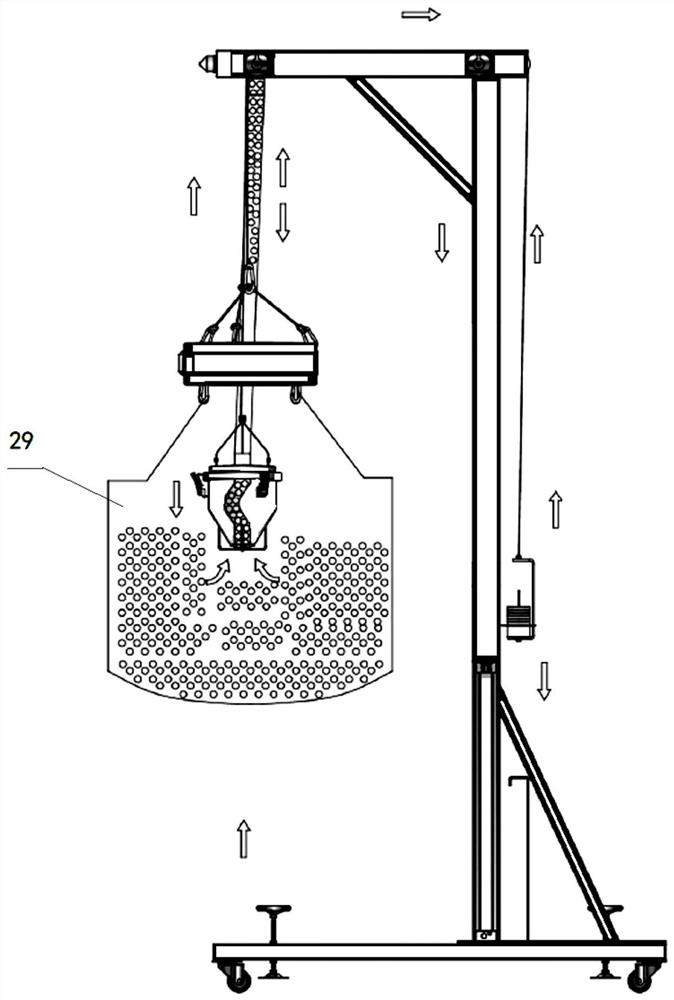

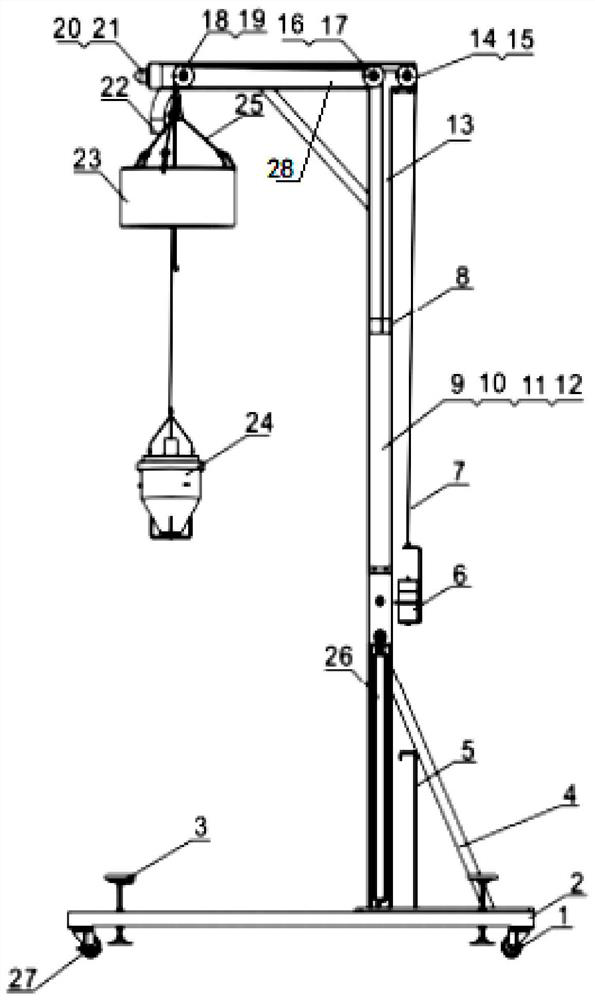

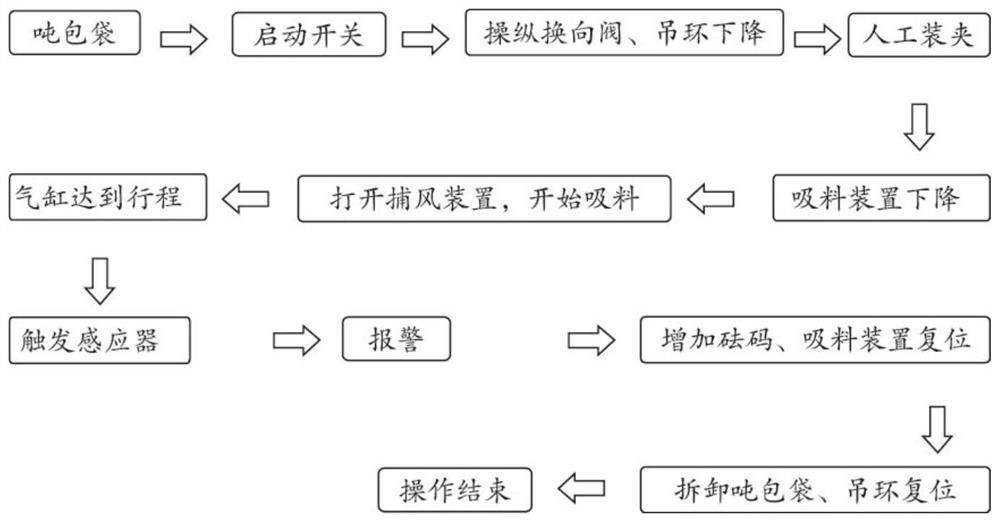

[0023] Such as Figure 1-2 As shown, a fast feeding device for injection molding equipment of the present invention includes a bracket, and one end of the top of the bracket is provided with a first pulley 14, a first wire baffle 15, a second pulley 16, a second wire baffle 17, and the other end Set the third pulley 18, one end of the first steel wire rope 7 is connected with the weight set 6, and the other end is passed through the first pulley 14 and the third pulley 18 in turn, and passes through the suspension ring 23 and is connected with the suction device 24 , the bottom of the suction device 24 is provided with a feed port for sucking the material in the ton bag 29, and the top of the suction device 24 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com