Automatic binding and welding equipment for steel bars of highway T-beam wing plate and using method of automatic binding and welding equipment

A beam and wing plate and equipment technology is applied in the field of automatic binding and welding equipment for the reinforcement of the T beam and wing plate of the highway, which can solve the problems of low processing and installation efficiency of the steel bar of the T beam and wing plate, time-consuming and laborious, etc., so as to improve the binding and welding efficiency and release the manual labor. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention are described in detail below through the examples, and the following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations to the technical solutions of the present invention.

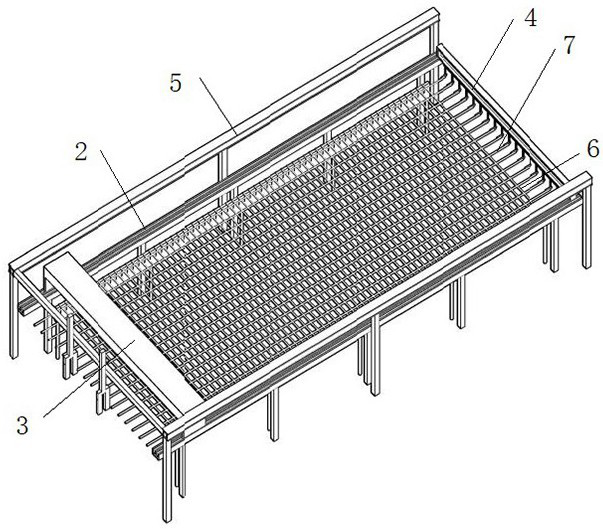

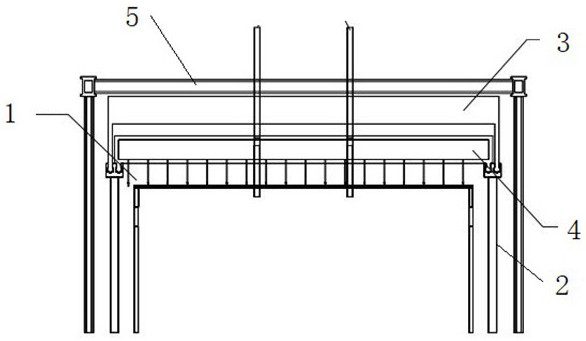

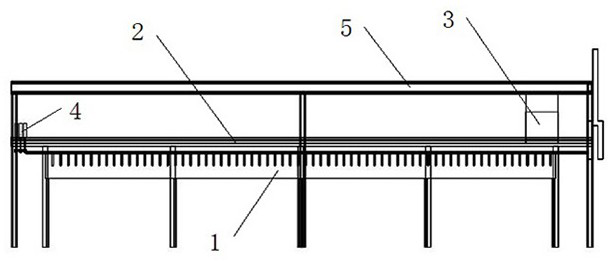

[0039] combine Figure 1-3 , an automatic binding and welding equipment for highway T-beam wing plate reinforcement, comprising,

[0040] The tire frame 1 is provided with a groove for placing the transverse steel bar 6 for positioning the transverse steel bar 6;

[0041] The equipment outer frame and guide rail 2 are set on the outer side of the tire frame 1, and both ends exceed the tire frame 1. The end beyond the tire frame 1 is equipped with an automatic welding device 3, and the other end beyond the tire frame 1 is installed with a longitudinal beam positioner 4;

[0042] The automatic binding and welding equipment 3 is slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com