Method for analysing quality defects

A quality defect and quality-related technology, applied in the direction of general control system, device for coating liquid on the surface, comprehensive factory control, etc., can solve problems such as impossible production rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

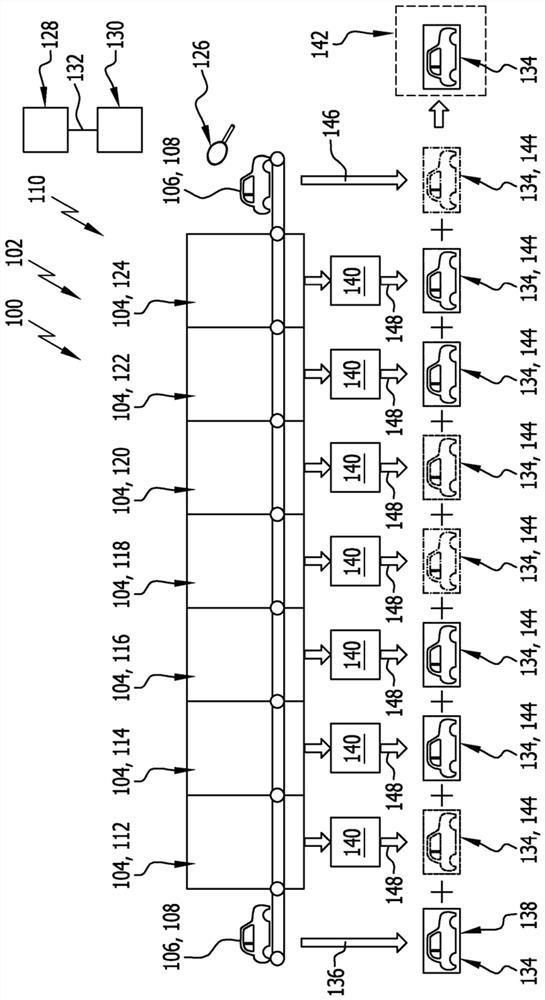

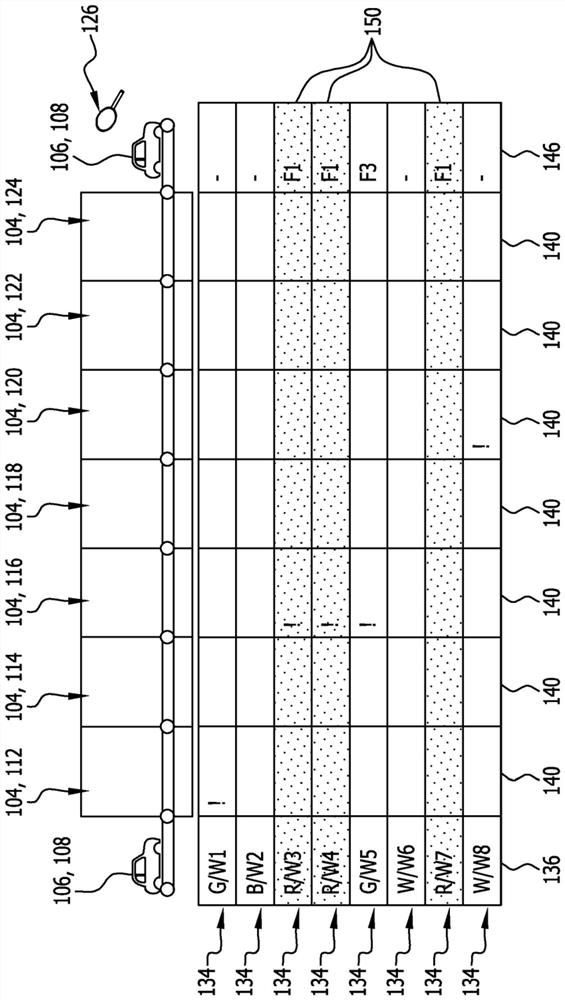

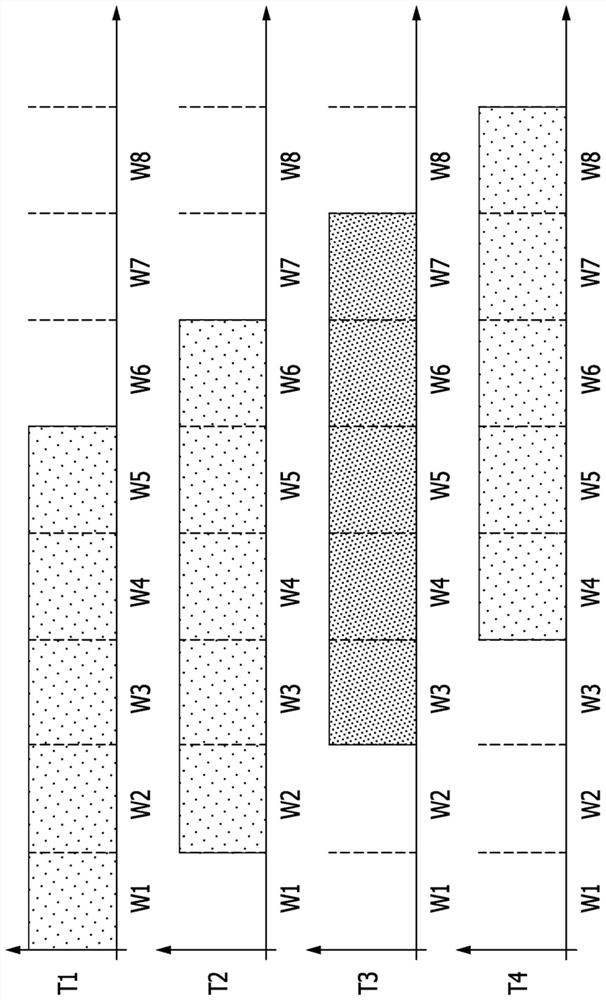

[0150] figure 1 Process flow equipment, generally indicated at 100, is shown.

[0151] The process plant 100 is in particular a painting plant 102 .

[0152] The process flow facility 100 preferably includes a plurality of processing stations 104 .

[0153] In this case, the process plant 100 , in particular the painting plant 102 , includes seven treatment stations 104 .

[0154] Preferably, a production process can be carried out on a workpiece 106 , in particular a vehicle body 108 and / or a vehicle accessory, by means of the process plant 100 .

[0155] In particular, one or more process steps of the production process can each be carried out in a plurality of processing stations 104 .

[0156] figure 1 The illustrated process plant 100 , in particular the painting plant 102 , is here in particular a painting line 110 .

[0157] In the coating line 110, the processing stations 104 are preferably connected in series with each other.

[0158] For example, it is conceiva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com