Intelligent monitoring management system for production workshop

An intelligent monitoring and management system technology, applied in transmission systems, closed-circuit television systems, time registers, etc., can solve the problems of high cost, worker monitoring and analysis, and increase in processes, and achieve low cost, high positioning accuracy, and improved productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

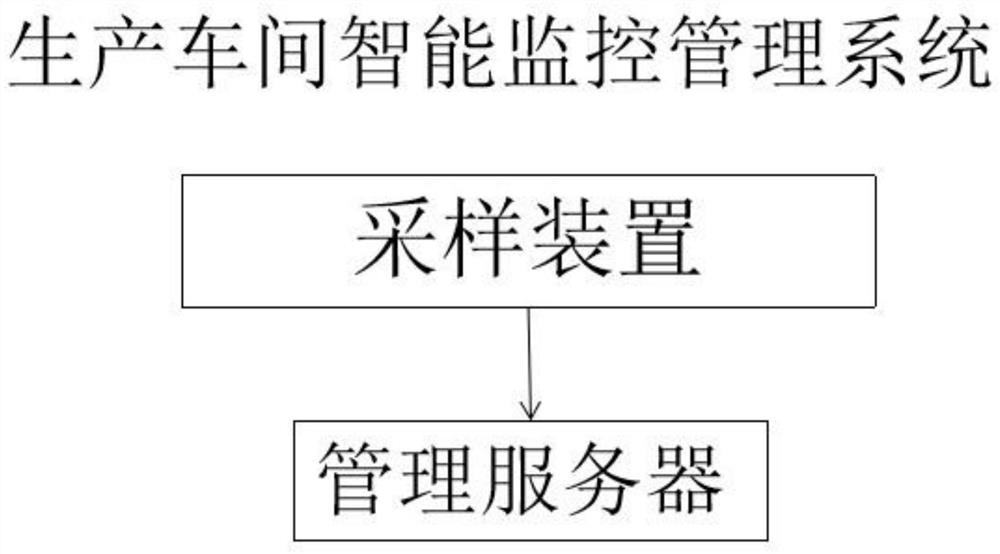

[0017] refer to figure 1 , the production workshop intelligent monitoring and management system provided by the embodiment of the present invention includes a sampling device and a management server, wherein: the sampling device is used to sample the location information and image information of each worker in the factory in real time and send the location information and image information to the management The server, wherein the sampling device uses a spatial positioning algorithm to perform spatial positioning processing on the objects included in the at least one scene video, and collects at least one object positioning data.

[0018] In an embodiment of the present invention, at least one camera is installed in the factory, such as a camera, that is, the installed camera needs to ensure that the formed shooting range covers the targe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com