Flexible flow shop combinatorial scheduling rule generation method considering batch processing

A flexible flow workshop and batch processing technology, applied in the direction of control/regulation systems, instruments, comprehensive factory control, etc., can solve problems such as single dimension and cannot be solved directly, and achieve the effect of improving algorithm performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

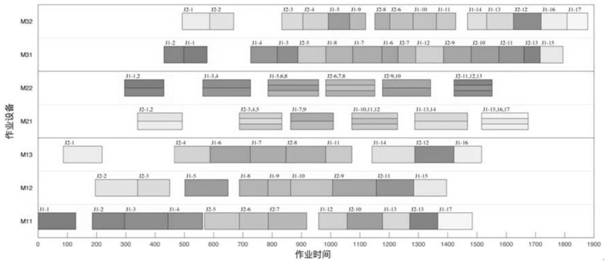

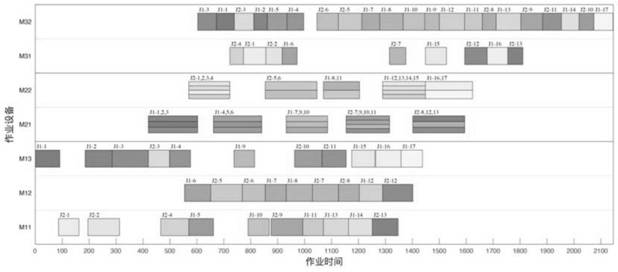

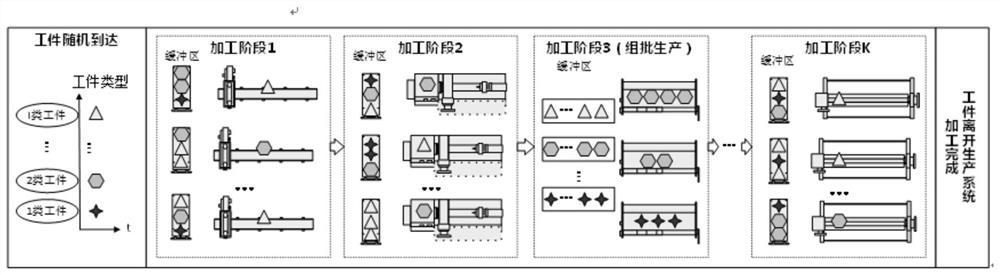

[0173] Using an improved gene expression programming algorithm. Design the relevant parameters of the calculation example, the number of production stages obeys the uniform distribution U(3,7), and the batch processing stage B k at No. stage and the batch processor capacity B obeys the uniform distribution U(2,6), the number of workpiece types obeys the uniform distribution U(2,6), the workpiece scale obeys the uniform distribution U(300,1000), and the equipment utilization follows the uniform distribution U( 0.5,0.9); the delivery time stress factor obeys the uniform distribution U(4,8), and the present invention sets three levels respectively according to the distribution range of the calculation example parameters.

[0174] Set relevant parameters for each calculation example, and set the job time distribution for the discrete process of the batch process. Batch process processing time p b Obey the uniform distribution U(100,200), discrete process processing time p d O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com