Clamp for testing shear performance of composite material

A technology of composite materials and fixtures, which is applied in the direction of analyzing materials, measuring devices, and strength characteristics. It can solve problems such as difficulties in precise positioning and alignment, bending deformation of fixtures, and cumbersome disassembly and assembly of samples, so as to avoid stress concentration and solve positioning problems. Effect on medium and strong adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

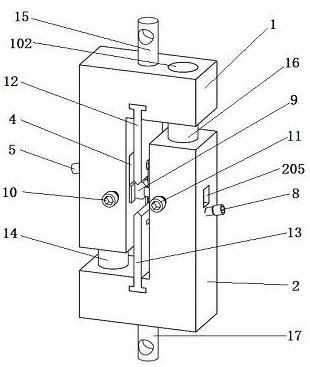

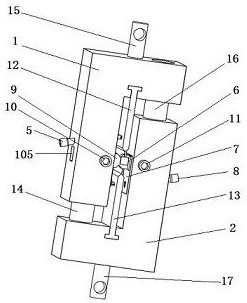

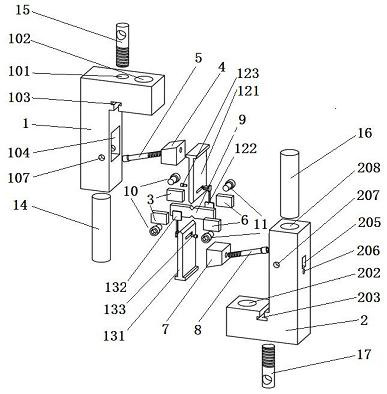

[0037] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present application will be clearly and detailedly described below in conjunction with the drawings in the embodiments of the present application.

[0038] Attached below Figure 1 to Figure 10 The present invention is described in further detail.

[0039] This embodiment provides a fixture for testing the shear performance of composite materials, including an upper pressing block 1, a lower pressing block 2, an upper rectangular spacer 3 and a lower rectangular spacer 6, a left wedge locking block 4 and a right side Wedge locking block 7, V-notch beam sample 9, left fastening bolt 5 and right fastening bolt 8, upper clamping bolt 10 and lower clamping bolt 11, upper centering device 12 and lower centering device 13. The upper rail column 14 and the lower rail column 16 as well as the upper loading rod 15 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com