Magnetic steel magnetization equipment for magnetic steel production

A technology of magnetic equipment and magnetic steel, applied in the direction of conveyor objects, measuring devices, instruments, etc., can solve the problems of low magnetization efficiency, no unloading function, and inability to meet the demand for magnetic steel, and achieve increased stability , Improving the effect of magnetizing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

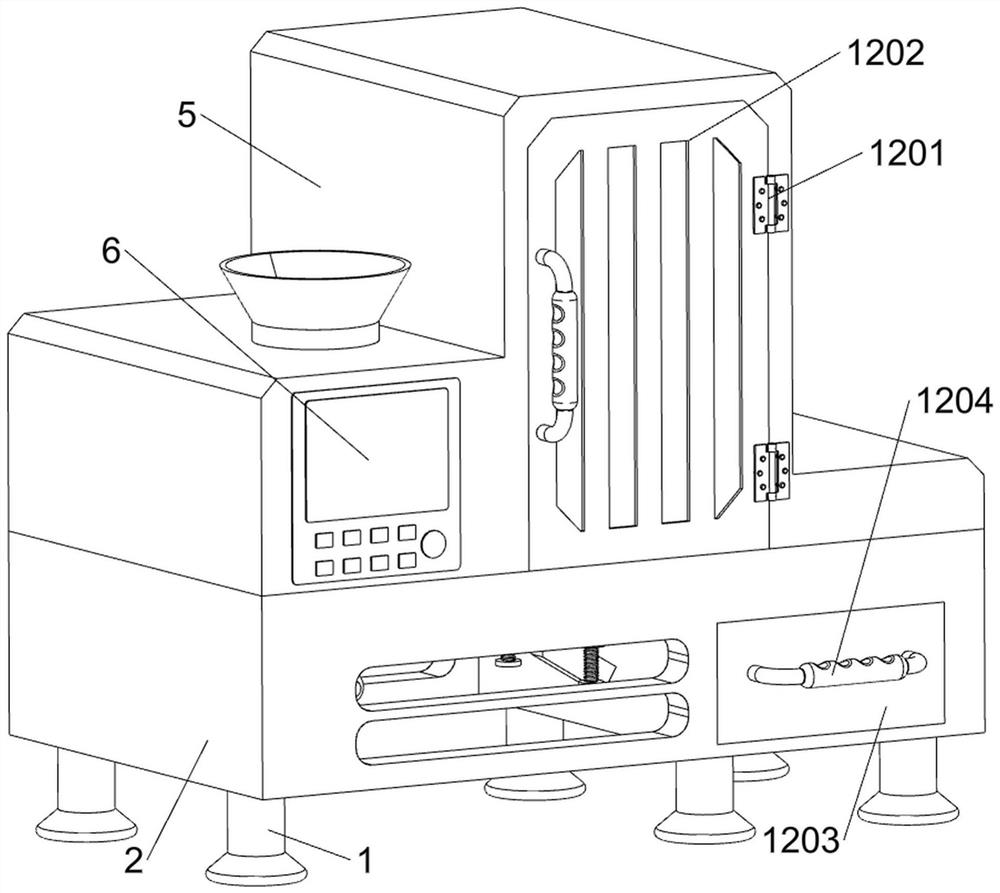

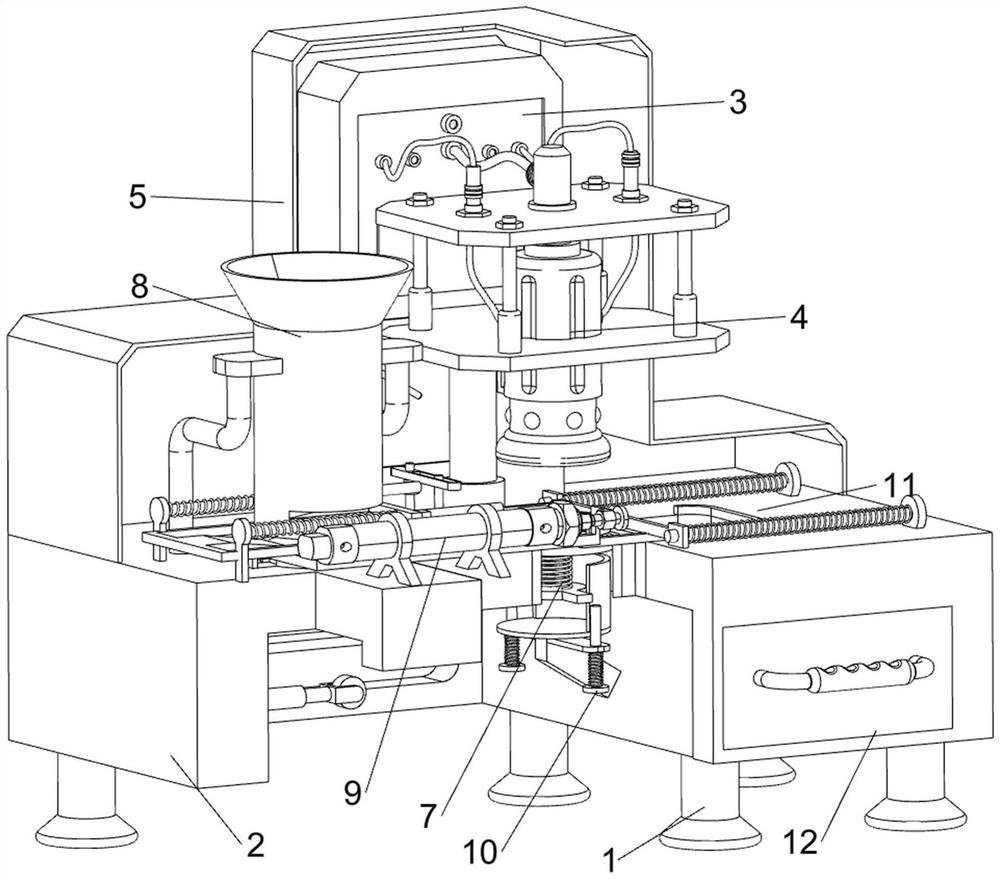

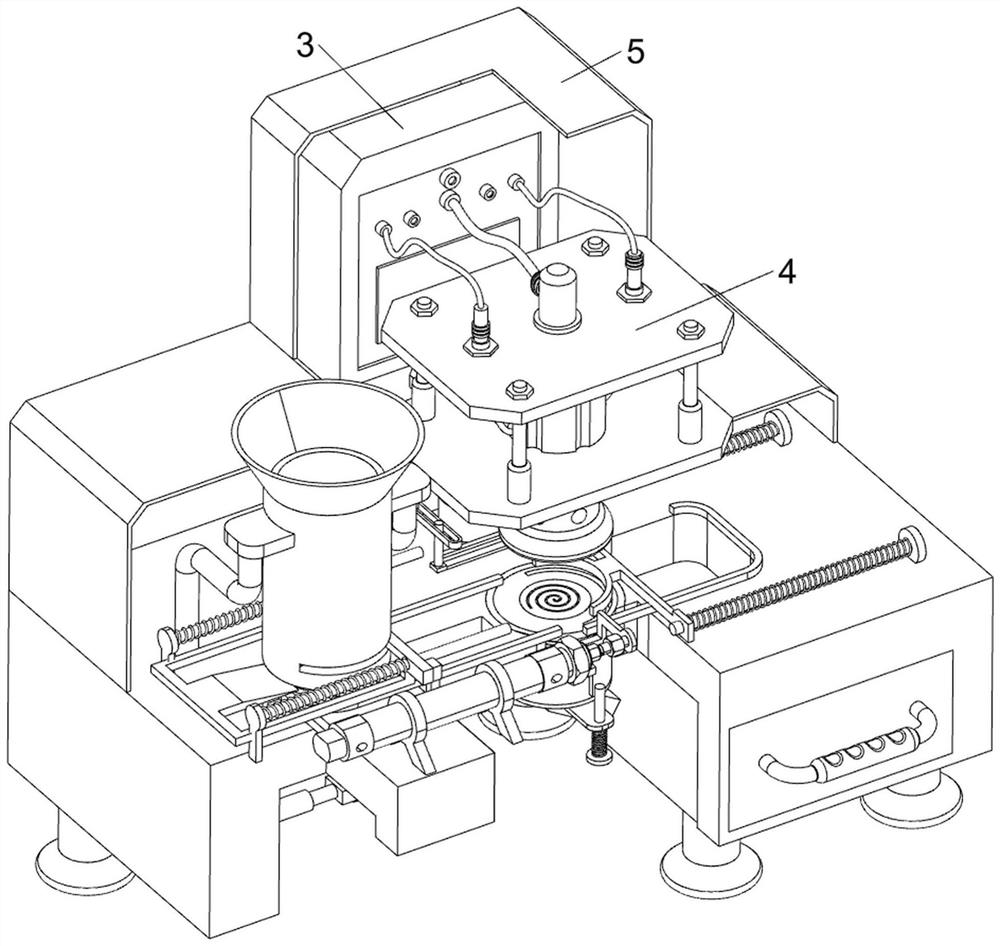

[0035] A kind of magnetic equipment for magnetic steel during the production of magnetic steel, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 10 As shown, it includes a support column 1, a workbench 2, an electric control box 3, a magnetization module 4, a protective frame 5, a control panel 6, an ejection assembly 7, a discharge assembly 8 and a push assembly 9, and the workbench 2 There is a groove on the right front side of the top, three support columns 1 are provided on the front and rear sides of the bottom of the workbench 2, a protective frame 5 is provided on the top of the workbench 2, an electric control box 3 is provided on the rear side of the top of the workbench 2, and the electric control box 3 Located on the rear side of the protective frame 5, the top and rear side of the workbench 2 is provided with a magnetization module 4, which is connected to the electric control box 3 through wires, and the magnetization mo...

Embodiment 2

[0041] On the basis of Example 1, such as figure 1 , Figure 5 , Figure 7 , Figure 8 , Figure 9 , Figure 11 , Figure 12 , Figure 13 , Figure 14 with Figure 15 As shown, a positioning assembly 10 is also included, and the positioning assembly 10 includes a telescopic rod 1001, a pulley 1002, a third spring 1003, a second guide rod 1004, a wedge block 1005, a positioning block 1006 and a fourth spring 1007, and the push rod 903 The right side of the lower part is provided with a telescopic rod 1001, the right side of the telescopic rod 1001 is slidingly provided with a pulley 1002, a third spring 1003 is provided between the pulley 1002 and the telescopic rod 1001, and a second guide rod 1004 is provided on the front and rear sides of the bottom of the guide ring 701 The second guide bar 1004 is slidingly provided with a wedge block 1005, the pulley 1002 is combined with the wedge block 1005, the inside of the guide ring 701 is slidingly provided with a positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com