Panel system having mounting and hinge assembly with mounting profile and hinge

A technology of hinge components and panels, applied in the direction of roof, roof cladding, construction, etc., to achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

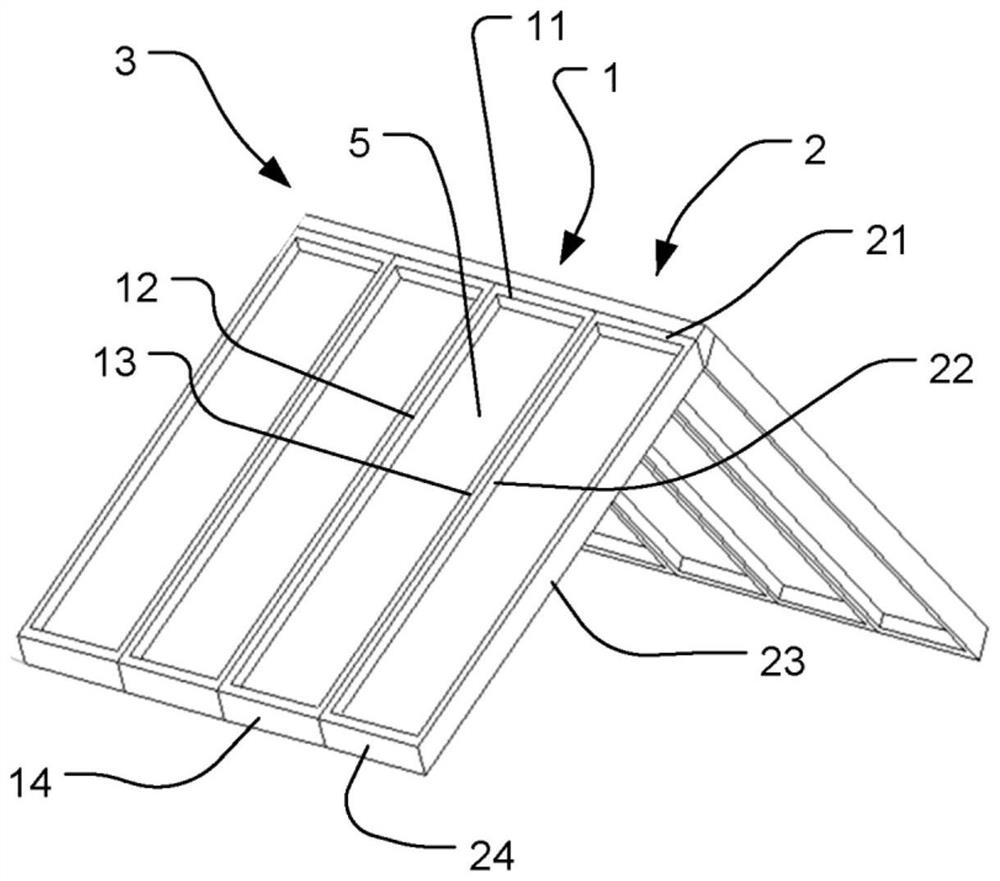

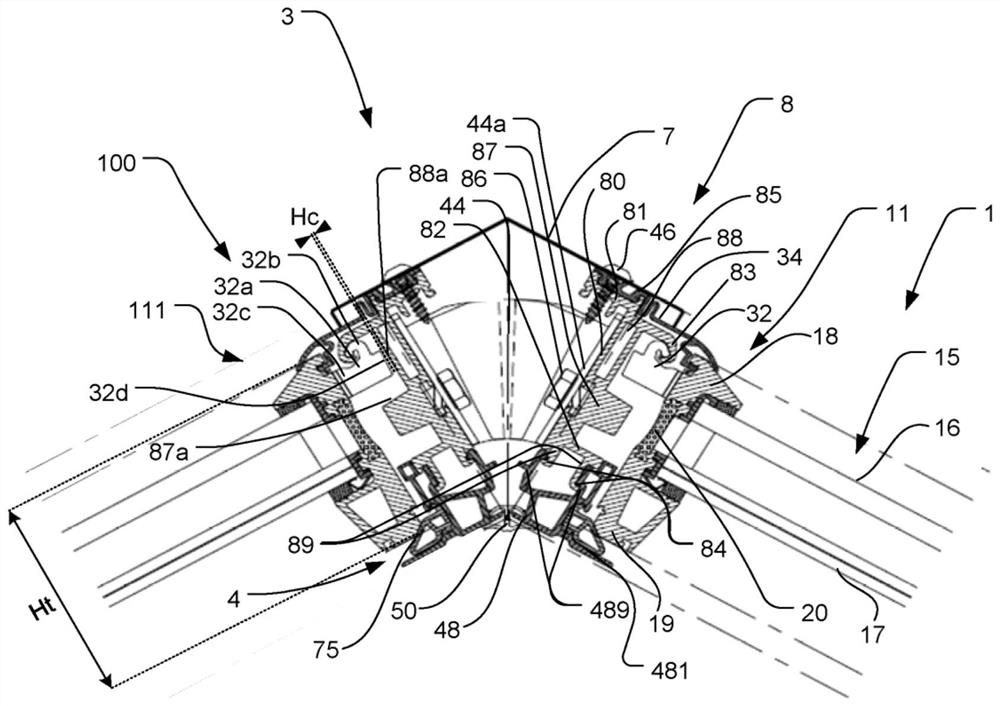

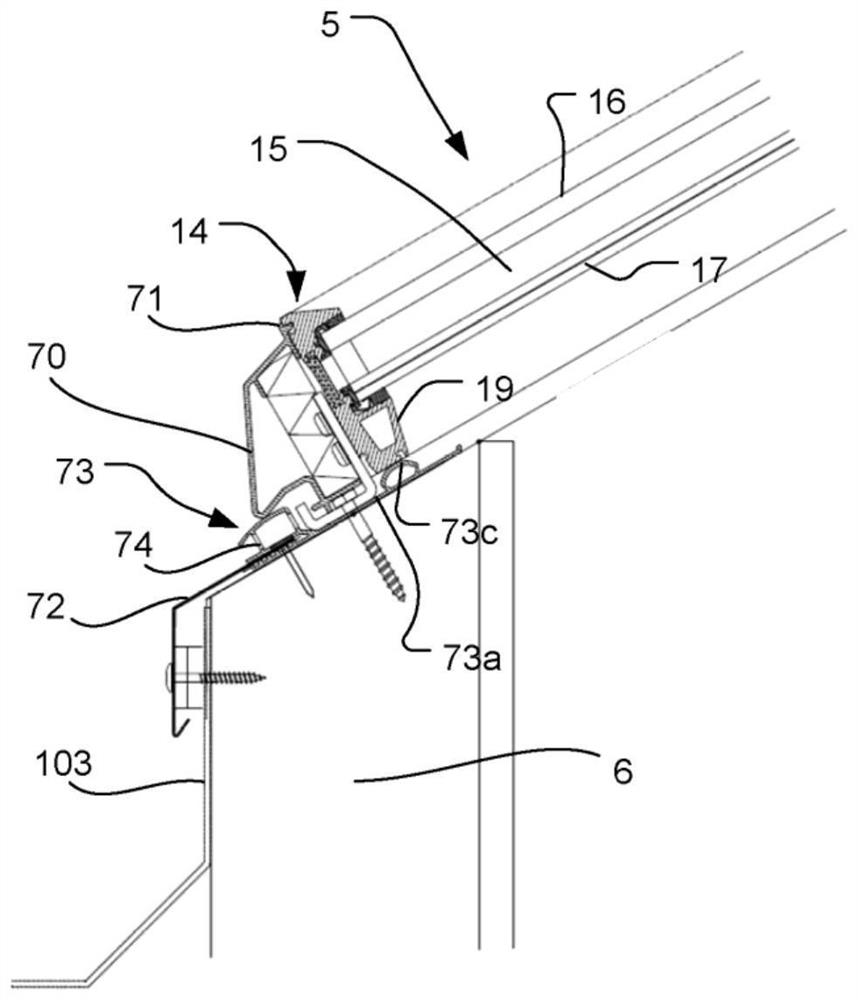

[0038] Figures 2 to 8 - First embodiment: panel structure in two-layer IGU, and various installation configurations

[0039] The principle of the structure of the profile element will now be described with reference to a first embodiment. It is pointed out that the described structure of the profile elements can in principle be applied to any one of the top profile element 11, the two side profile elements 12, 13 and the bottom profile element 14 of the fixed panel 1, and for possible Any one of the top profile element 21 , the two side profile elements 22 , 23 and the bottom profile element 24 of the panel 2 is opened.

[0040] will refer to figure 2 The top profile element 11 is depicted in the cross-sectional view of the fixed panel 1 shown in and a second fixed panel 100 positioned opposite the fixed panel 1 . In the first installation configuration, the fixed panel 1 and the second fixed panel 100 can be formed as figure 1 Part of the panel system 3 shown in , i.e...

no. 2 approach

[0063] Figure 9 -Second embodiment: a panel structure in the form of a three-layer IGU

[0064] Figure 9 in with Figure 8 A second embodiment of the panel system 3 is shown in the corresponding view to the first embodiment. The panel system 3 of the second embodiment also comprises one or more fixed panels and one or more openable panels, wherein adjacent fixed panels 1 and openable panels 2 are shown. In this second embodiment, the paneling element 5 comprises a three-layer IGU 15' having three glass sheets, such that the three-layer IGU 15'

[0065] like Figure 8 and Figure 9 As shown in , the insulating member 20 is an elongated element comprising protrusions 20a at both ends. The insulating member 20 has a thickness T extending in an axial direction A, which is a plane parallel to the surface of the IGU 15 , ie to the outer pane 16 and the inner pane 17 . The heat insulating member 20 has a height H extending in the longitudinal direction L of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com