Tooling for preparing blade thermal barrier coating

A technology of thermal barrier coating and tooling, applied in metal material coating process, coating, vacuum evaporation coating, etc., can solve the problems of difficult control of deposited coating, uncontrollable swing speed, limited inclination angle, etc., to achieve Improve uniformity and strain tolerance, achieve thickness and structure control, and extend service life effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

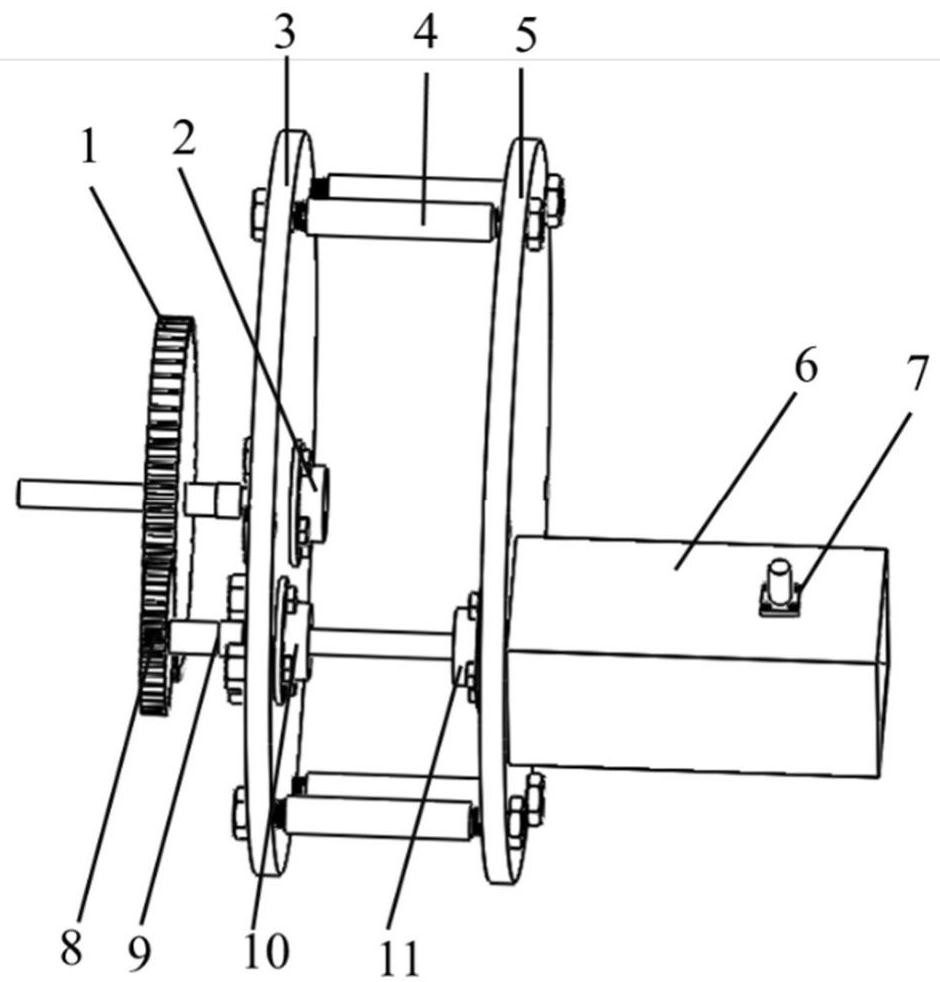

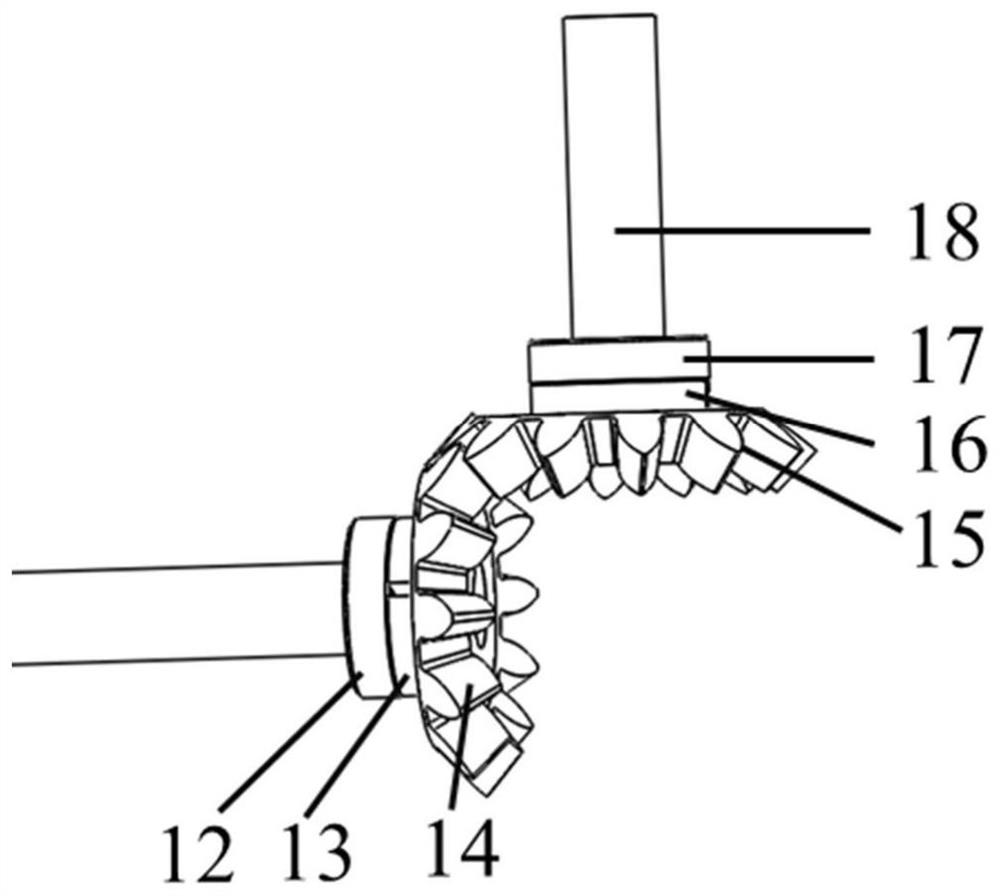

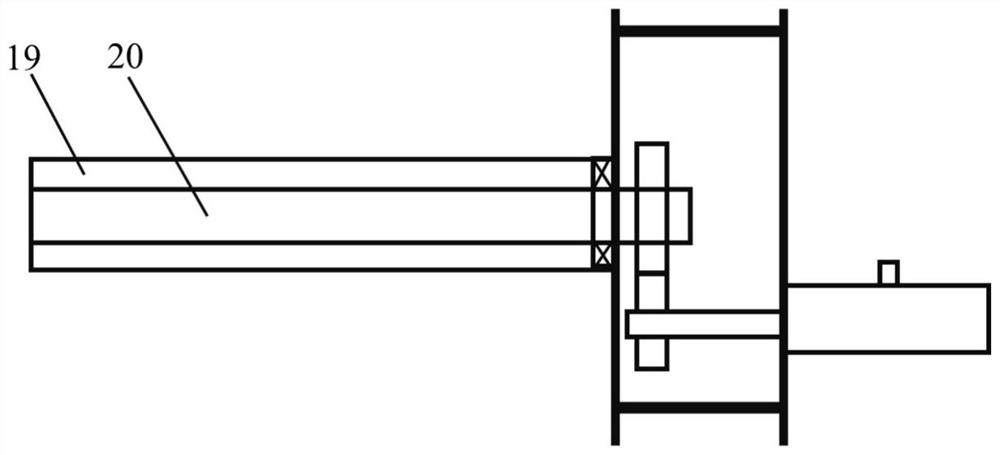

Method used

Image

Examples

Embodiment 1

[0055] Using the tooling of the present invention, the guide vane and the sample rotation axis are fixed, and the coating is prepared by EB-PVD. The equipment swing main shaft drives the entire tooling to swing by ±50° through the change of the rotation direction; at the same time, the rotation of the main rotation axis drives the rotation of the slave rotation axis, thereby driving the rotation of the sample rotation axis, and finally drives the rotation of the guide vane connected to the sample rotation axis. Finally, it is realized that the guide vane can rotate and swing simultaneously during the preparation of the coating.

[0056] attached Figure 5 For the cross-sectional topography of the coating of the blade body part of the guide vane prepared by the tooling of the present invention, the coating can be prepared by using the tooling of the present invention to realize the preparation of a dense columnar crystal structure coating on the blade body of the guide vane.

...

Embodiment 2

[0060] Utilizing the tooling of the present invention, the turbine blade and the rotation axis of the device sample are fixed, and the swing main shaft of the EB-PVD equipment drives the entire tooling to swing within the range of 0 to 90° through the change of the rotation direction; at the same time, the rotation of the main rotation axis drives the rotation of the slave rotation axis, thereby Drive the rotation axis of the sample to rotate, and finally drive the guide blade connected with the rotation axis of the sample to rotate. Finally, the turbine blades can rotate and swing simultaneously during the preparation of the coating.

[0061] attached Figure 10 It is the cross-sectional appearance diagram of the coating of the turbine blade blade pot part prepared by the tooling of the present invention, attached Figure 11 For the cross-sectional topography of the coating on the back of the blade of the turbine blade prepared by the tooling of the present invention, from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com