Electromagnetic relay contact part laser brazing method and system and clamp

A technology for electromagnetic relays and contact parts, applied in relays, circuits, welding equipment, etc., can solve problems such as insufficient control of the operation process, deterioration of relay sealing quality, large deformation of weldments, etc., and achieve the effect of avoiding being burned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

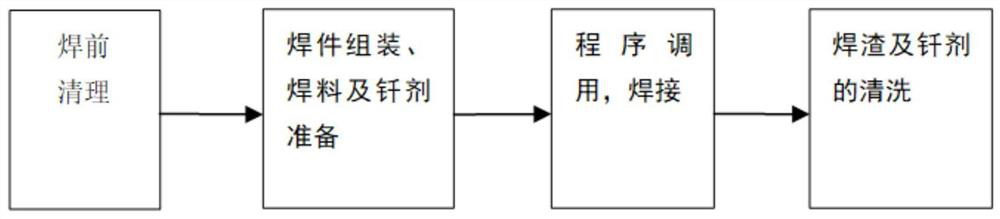

Method used

Image

Examples

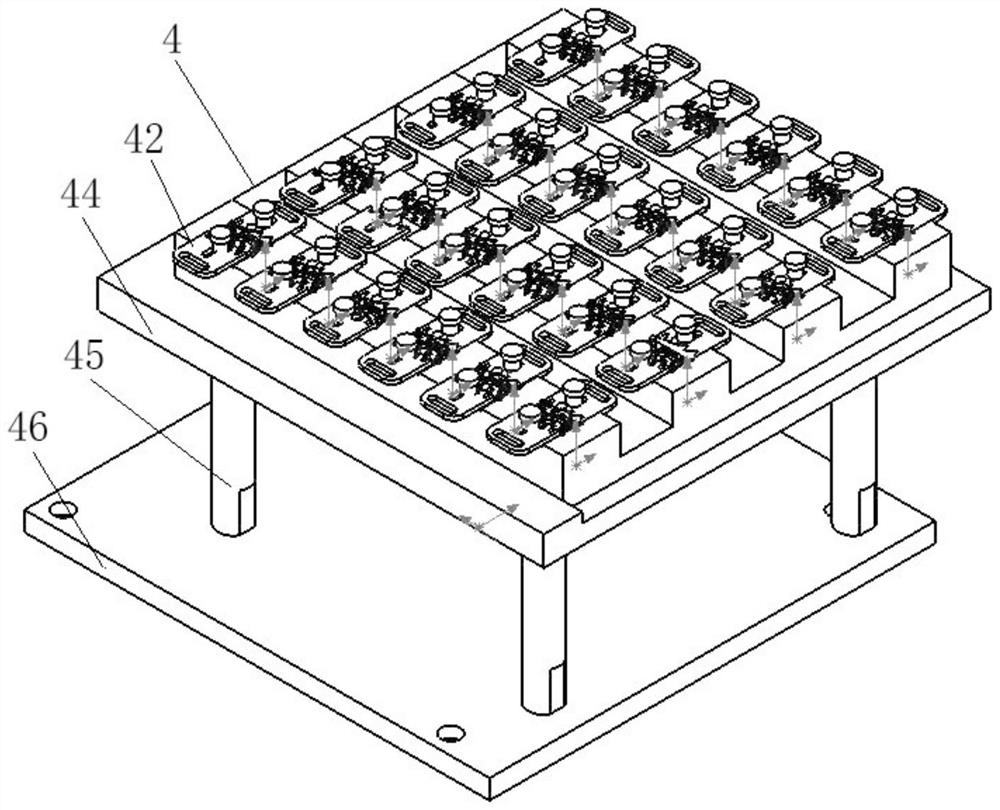

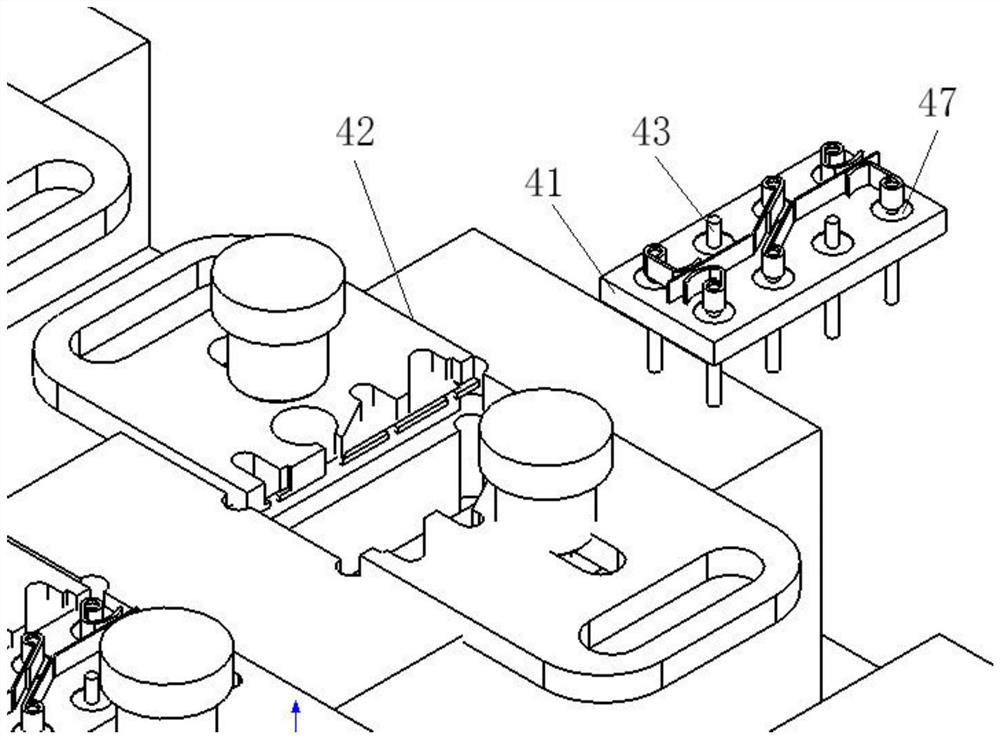

Embodiment Construction

[0035] An example embodiment will now be described more fully with reference to the accompanying drawings. However, an example embodiment can be implemented in a variety of forms, and is not to be construed as being limited to the examples set forth herein; in contrast, providing these embodiments will make the invention will be more comprehensive and complete, and the concept of an example embodiment is fully conveyed. Those skilled in the art will.

[0036] Moreover, the features, structures, or characteristics described may be incorporated in one or more embodiments in any suitable manner. In the following description, there is provided a number of specific details to give sufficient understanding of the embodiments of the invention. However, those skilled in the art will appreciate that there may be one or more of the invention without one or more of a particular detail, or other methods may be employed. In other cases, it is not shown or described in detail or described to av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com